Press bound type water valve

A water valve and valve core technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of product service life, water valve blockage, wear and other problems, and achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

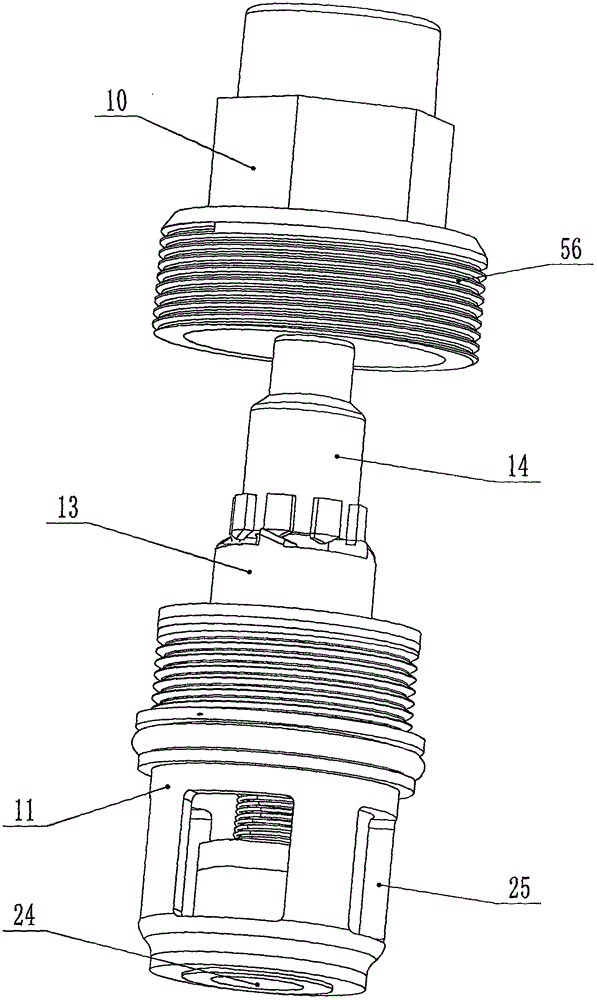

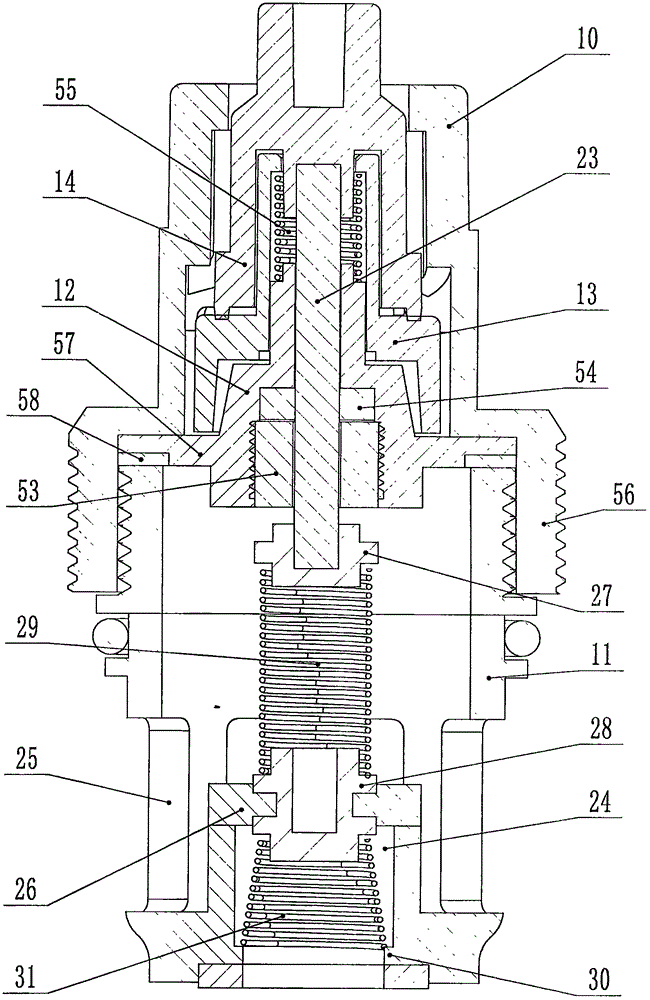

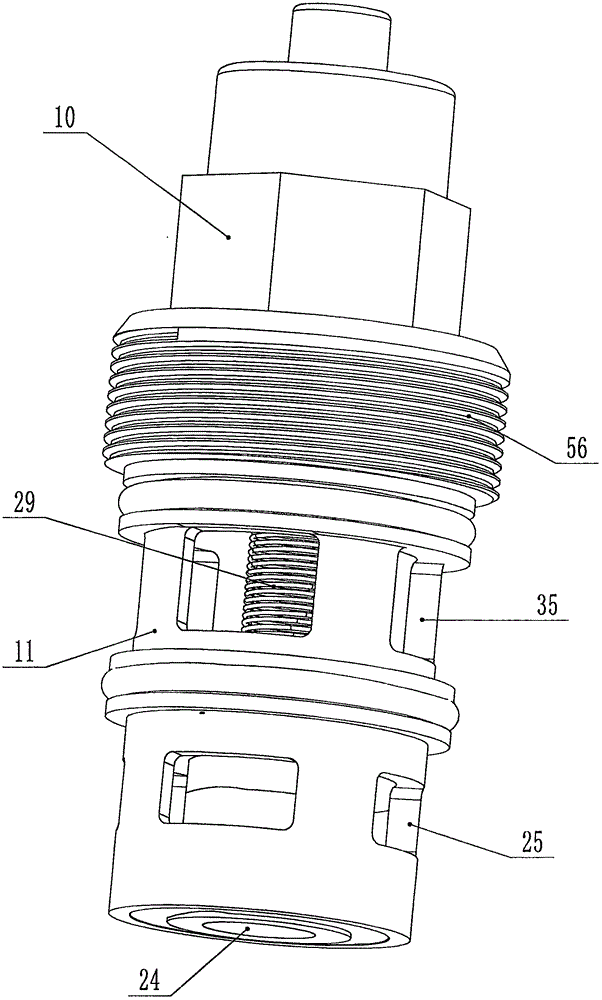

[0036] refer to Figures 1 to 9 , is a push-and-bounce water valve disclosed in the present invention, comprising an upper housing 10 and a lower housing 11 fixedly connected to the upper housing 10, a guide sleeve 12 is provided between the upper housing 10 and the lower housing 11, The guide sleeve 12 in the upper housing 10 is provided with a rotating sleeve 13, the rotating sleeve 13 is provided with a pressure sleeve 14, and the rotating sleeve 13 is provided with several protrusions 15 arranged at intervals along the circumference. The top faces of the tops are all provided with an inclined surface 16 downwards in the counterclockwise direction, and the lower end of the pressure sleeve 14 is provided with several convex teeth 17 arranged at intervals, and the lower end surface of the convex teeth 17 is provided with an inclined surface 16 that matches the inclined surface 16. The inclined surface 2 18 of the upper housing 10 is evenly distributed along the circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com