Turbulence anti-clogging dripper

A dripper and flow channel technology, applied in the field of agricultural production irrigation equipment, can solve the problems of easy clogging drip irrigation system, unable to operate normally, poor turbulent effect, etc., and achieve the effect of reducing cost, improving anti-clogging performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

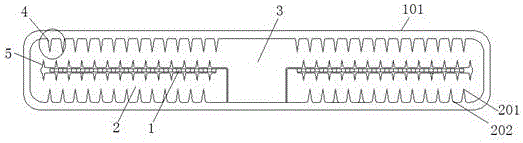

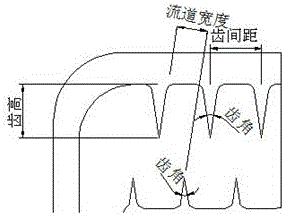

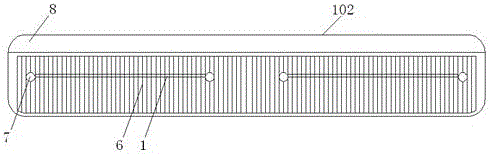

[0017] A turbulent flow anti-clogging dripper, comprising a dripper body front 101 and a dripper body back 102, the dripper body front 101 includes a water inlet filter window 1, a flow channel 2 and a water outlet tank 3, and the dripper body back 102 is formed by a screening recess The platform 7 and the weight-reducing platform 8 are composed; the water inlet filter window 1 is located at the symmetrical position on both sides of the water outlet tank 3, the flow channel 2 is connected with the water outlet tank 3, the water outlet tank 3 is located in the middle of the front side 101 of the dripper body, and the back side 102 of the dripper body is along the In the length direction, there are screening concave platforms 7 and weight-reducing platforms 8 at both ends of the water inlet filter window 1; the water inlet filter window 1 adopts a horizontal straight filter window; Composed of long teeth 4 and short teeth 5, short teeth 4 are used in the middle of the toothed dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com