A kind of calcium carbonate sheet and preparation technology thereof

A calcium carbonate and particle size technology, applied in the field of health food, can solve the problems of increasing bone density and low apparent absorption rate of calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

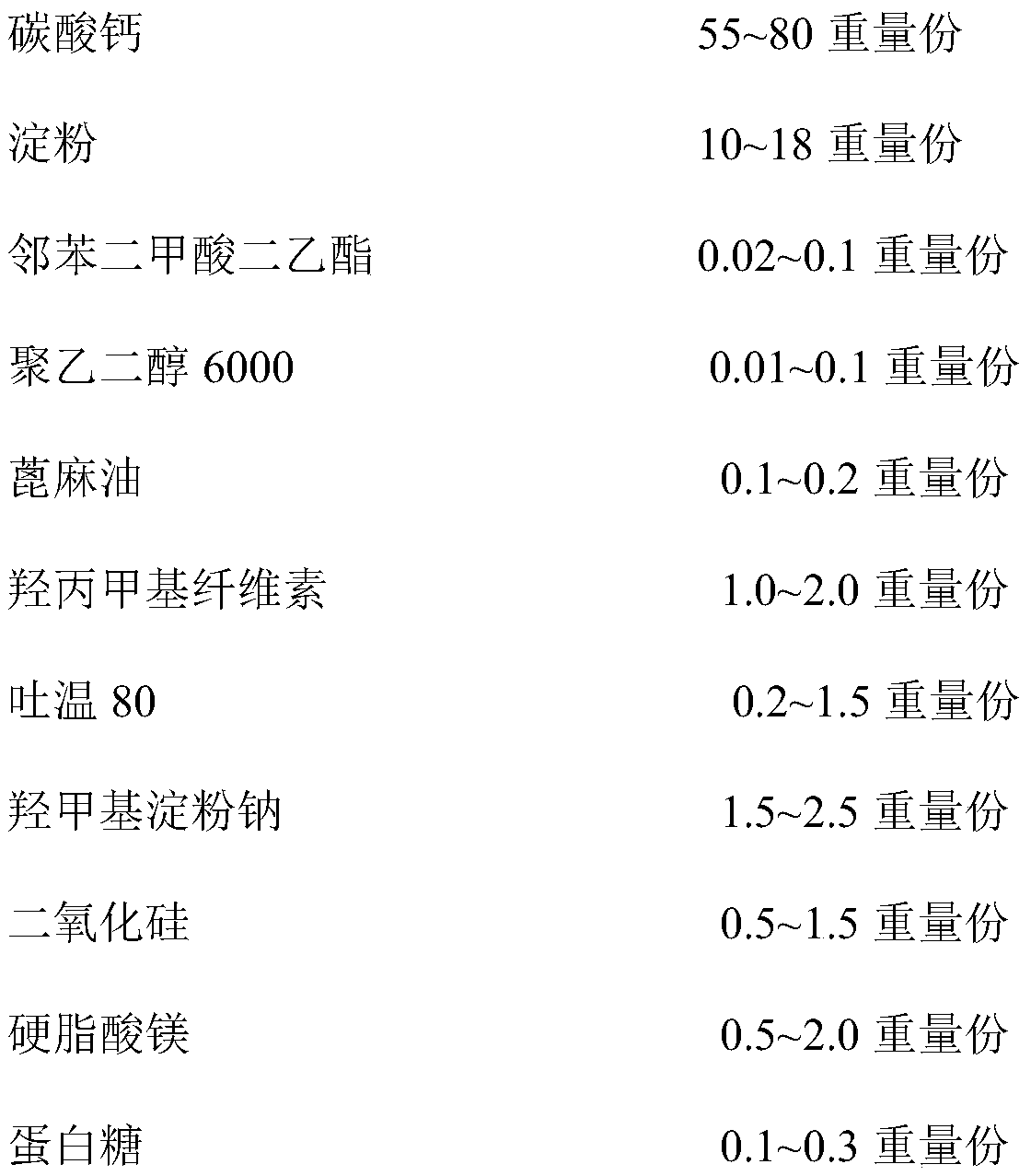

[0045] prescription:

[0046]

[0047] The particle size of the calcium carbonate is 80nm.

[0048] Preparation:

[0049] (1) Adhesive solution preparation

[0050] Weigh the prescribed amount of hydroxypropylmethylcellulose, disperse and dissolve it with ethanol to obtain the hypromellose ethanol solution; weigh the prescribed amount of starch, disperse it with purified water, add Tween 80, and take another boiling purified water Rush into it quickly to obtain starch paste; pour the hydroxypropyl methylcellulose ethanol solution into the starch paste, stir well and set aside;

[0051] (2) Granulation

[0052] Weigh calcium carbonate, diethyl phthalate, polyethylene glycol 6000, protein sugar and castor oil according to the prescription, put them into the wet granulator together, and mix well; pour the binder solution in step (1) into Mix uniform raw and auxiliary materials, make soft materials, stir, and make granules;

[0053] (3) Drying and granulation

[0054] The...

Embodiment 2

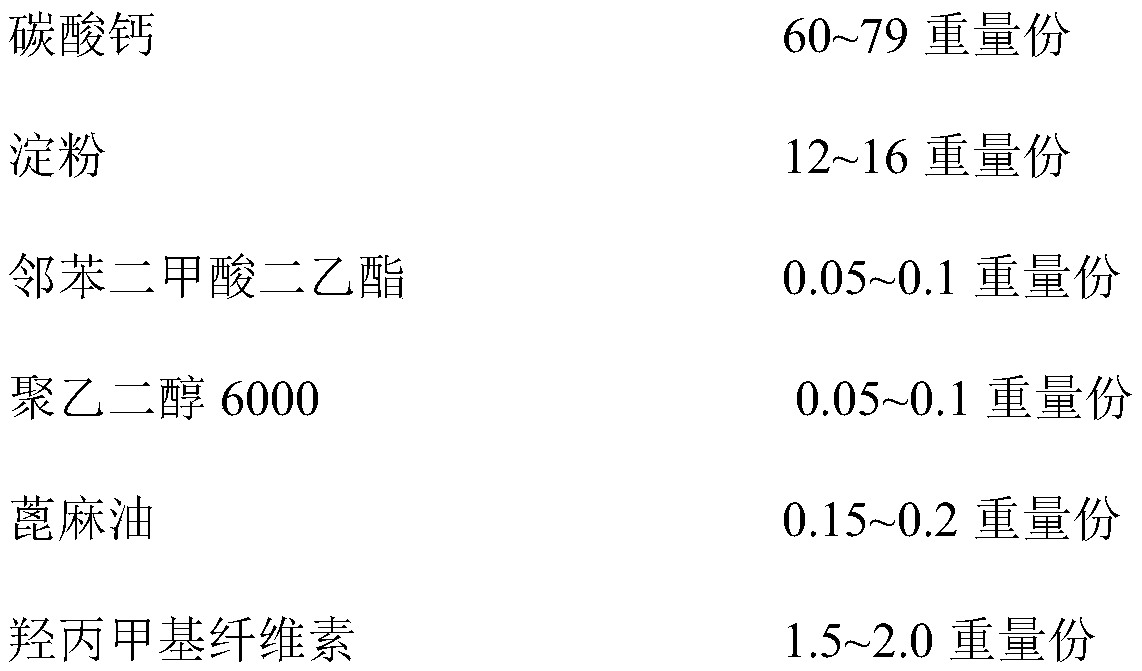

[0060] prescription:

[0061]

[0062] The particle size of the calcium carbonate is 160nm.

[0063] Preparation:

[0064] (1) Adhesive solution preparation

[0065] Weigh the prescription amount of hydroxypropyl methylcellulose, disperse and dissolve it with ethanol to obtain the hypromellose ethanol solution; weigh the prescription amount of starch, disperse it with purified water, add Tween 80, and take boiling purified water Rush into it quickly, obtain starch paste; Wherein, the weight ratio of hydroxypropyl methylcellulose and ethanol is 1:3, and the weight ratio of hydroxypropyl methylcellulose and purified water is 1:4; Pour the ethanol solution into the starch paste, stir well and set aside;

[0066] (2) Granulation

[0067] Weigh calcium carbonate, diethyl phthalate, polyethylene glycol 6000, protein sugar and castor oil according to the prescription, put them into the wet granulator together, and mix well; pour the binder solution in step (1) into Mix unifor...

Embodiment 3

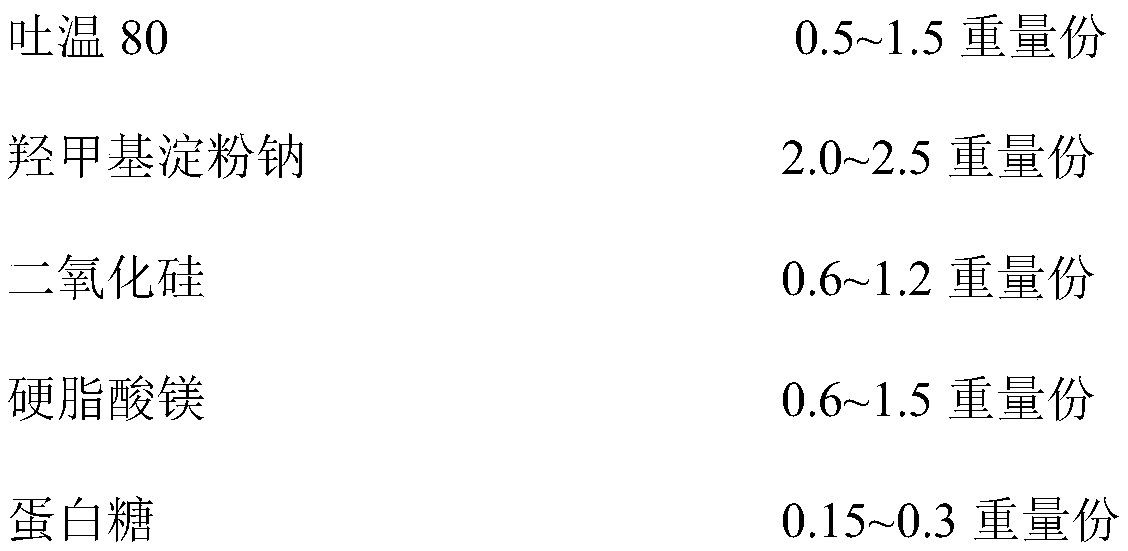

[0075] prescription:

[0076]

[0077]

[0078] The particle size of the calcium carbonate is 90nm.

[0079] Preparation:

[0080] (1) Adhesive solution preparation

[0081] Weigh the prescribed amount of hydroxypropylmethylcellulose, disperse and dissolve it with ethanol to obtain the hypromellose ethanol solution; weigh the prescribed amount of starch, disperse it with purified water, add Tween 80, and take another boiling purified water Rush into it quickly, obtain starch paste; Wherein, the weight ratio of hydroxypropyl methylcellulose and ethanol is 1:4, and the weight ratio of hydroxypropyl methylcellulose and purified water is 1:5; Pour the ethanol solution into the starch paste, stir well and set aside;

[0082] (2) Granulation

[0083] Weigh calcium carbonate, diethyl phthalate, polyethylene glycol 6000, protein sugar and castor oil according to the prescription, put them into the wet granulator together, and mix well; pour the binder solution in step (1) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com