Automatically-controlled building surface cleaning device and working method thereof

A surface cleaning device and building technology, applied in the direction of building structure, construction, cleaning machinery, etc., can solve the problems of low cleaning efficiency, unguaranteed safety, and inability to realize automatic control, so as to avoid unsafe, Efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

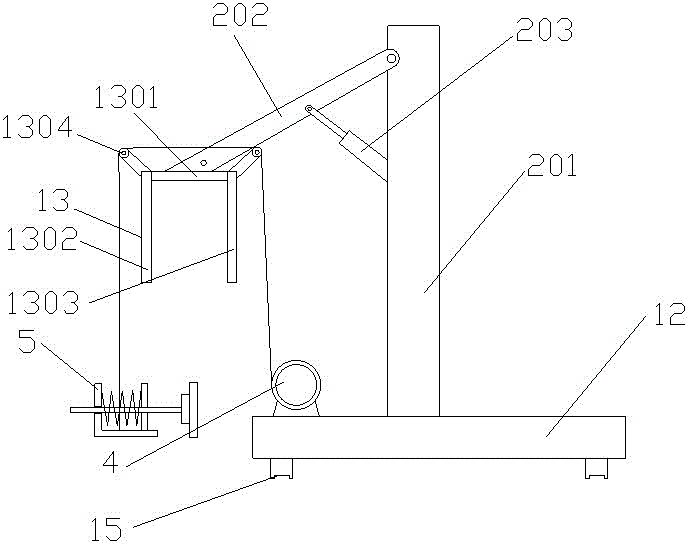

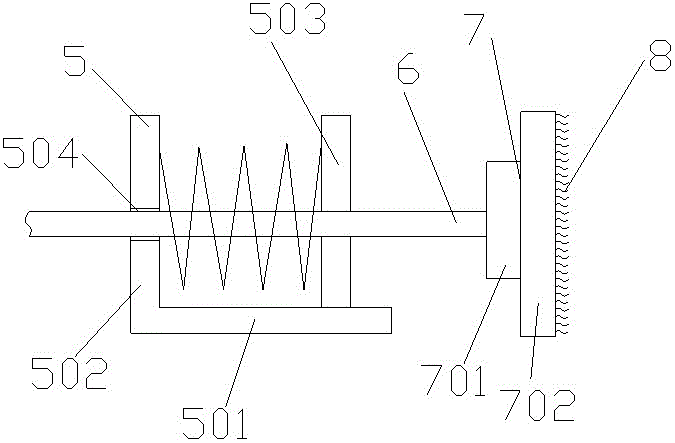

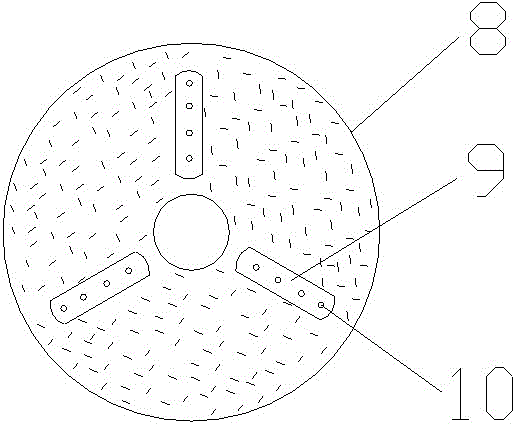

[0023] The automatic control building surface cleaning device of the present invention includes a frame 1 and a support frame 2 arranged on the frame 1, and the frame 2 is also provided with a winding mechanism 4 for winding cables 3, the The cable 3 outputs the cable through the winding mechanism 4 and crosses the support frame 2, and its end is connected to the support frame 5. The support frame 5 is threaded with a support shaft 6, and the end of the support shaft 6 is hinged on the turntable 7. On the inner end face, a cleaning cloth 8 is provided on the outer end face of the turntable 7; the turntable 7 includes a fixed plate 701, a moving plate 702 and a third motor arranged on the fixed plate to drive the moving plate to rotate; There is a guide rail, and the bottom of the frame is provided with a guide rail groove that can move along the guide rail; the winding mechanism is controlled by the first motor to retract and unwind the winding wire, and the guide rail groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com