Combined flue gas washing tank

A washing tank and combined technology, which is applied to combined devices, gas treatment, dispersed particle separation, etc., can solve the problems of low utilization rate of washing liquid, flue gas emission, and consumption of large washing liquid, and increase the initial investment and maintenance cost. , Guarantee the discharge standard, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with specific embodiments.

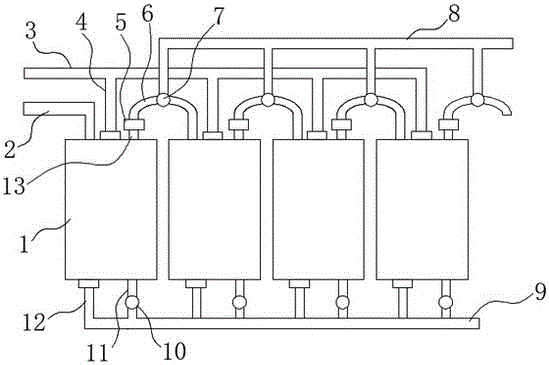

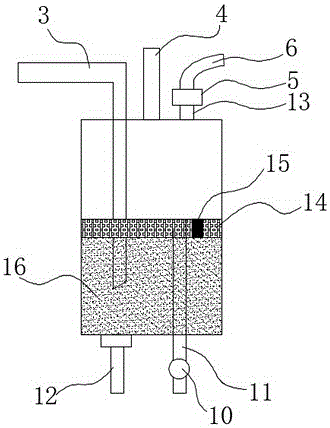

[0014] A combined flue gas washing tank proposed by the present invention includes a plurality of washing tank bodies 1 arranged side by side. The upper end of the washing tank body 1 is provided with an air inlet pipe 2, a liquid feeding pipe 4 and an air outlet pipe 13. The washing tank body 1 The lower end of the washing tank body 1 is provided with a drain pipe 12 and an overflow pipe 11, and the top of the washing tank body 1 is provided with a liquid filling pipe 3. A gas outlet main pipe 8 is provided, and the gas outlet pipe 13 of the washing tank body 1 communicates with the inlet pipe 2 of a washing tank body 1 adjacent to it through the connecting pipe 6, and one end of the connecting pipe 6 is connected to a washing tank body 1 through a first sleeve joint. The outlet pipe 13 is connected, and the other end of the connecting pipe 6 is connected to the inlet pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap