Shearing device for iron core

A shearing device and iron core technology, which is applied in the direction of shearing device, nibbling cutting device, and accessory device of shearing machine, etc. It can solve the problems of inability to adjust the iron core, difficulty in controlling the length of the iron core, and the production of the iron core. The equipment is not ideal enough to achieve the effect of compact structure connection and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

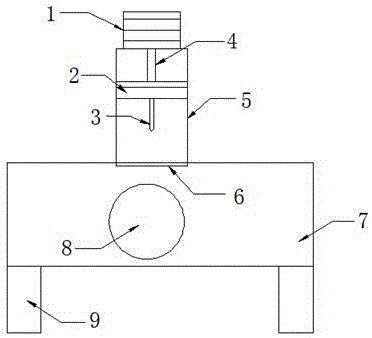

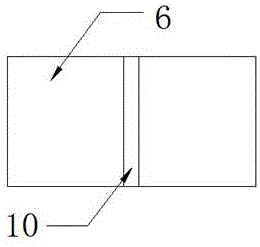

[0018] Example: such as Figure 1-2 As shown, a shearing device for iron core includes a drive motor 1, a connecting plate 2, a cutting knife 3, a telescopic rod 4, a support seat 5, a cutting plate 6, a frame 7, a rotating shaft 8, a leg 9 and a cutting Groove 10; the top of frame 7 is equipped with support seat 5, and the top of support seat 5 is provided with drive motor 1, and the bottom of drive motor 1 is provided with telescopic rod 4, and the bottom end of telescopic rod 4 is connected with connecting plate 2, connecting plate The bottom end of 2 is equipped with cutting knife 3, and the bottom end of frame 7 is equipped with four legs 9, and the inside of frame 7 is provided with rotating shaft 8, and the surface of frame 7 is provided with cutting board 6, and the middle part of cutting board 6 Cutting grooves 10 are provided.

[0019] As a technical optimization solution of the present invention, the rotating shaft 8 and the frame 7 are connected in rotation.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com