Buffer hinge suitable for thick door plate

A technology for hinges and door panels, which is applied to hinges with pins, hinges, door/window accessories, etc. It can solve problems such as inability to install and use, and achieve good cushioning effects, long service life, and easy installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

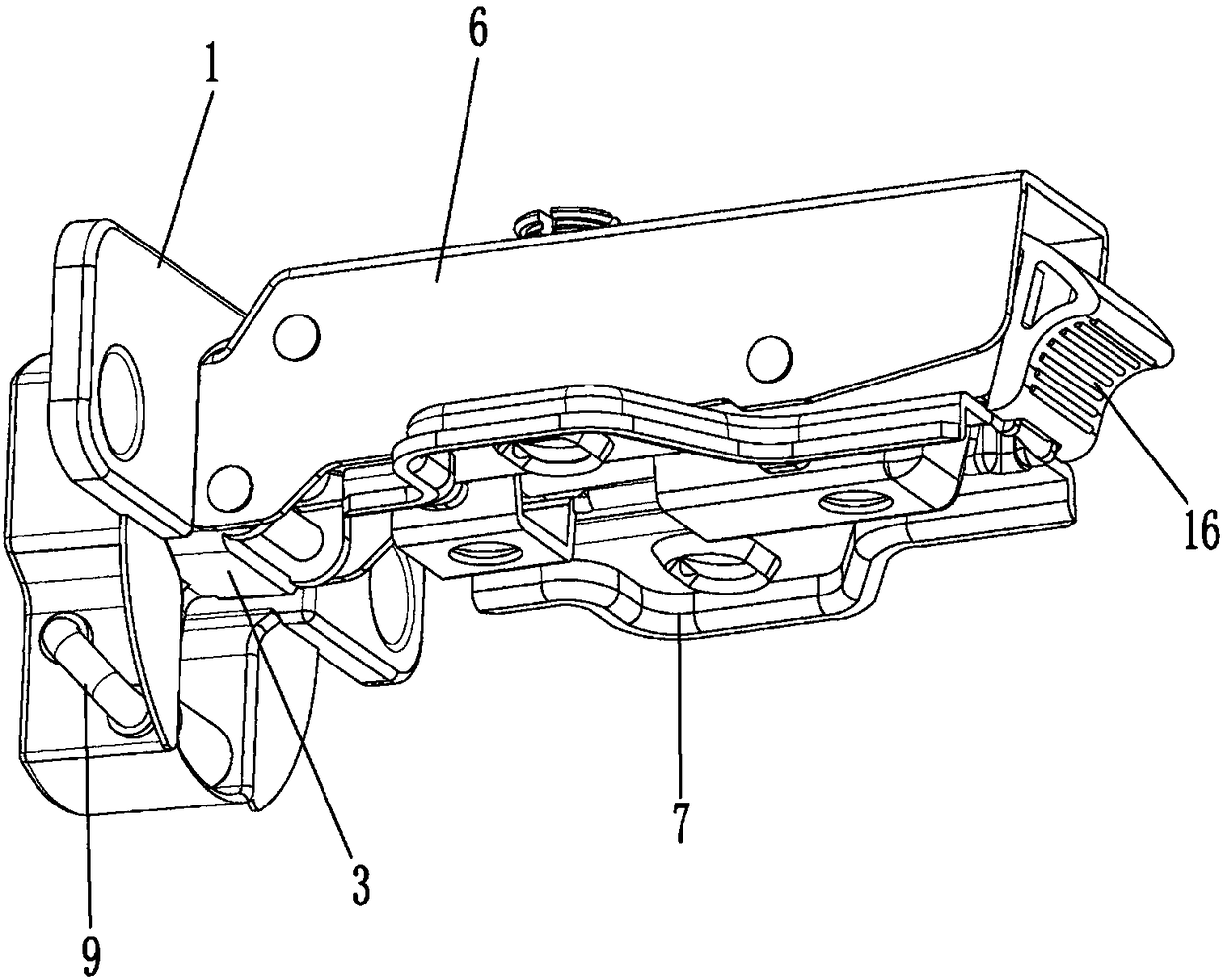

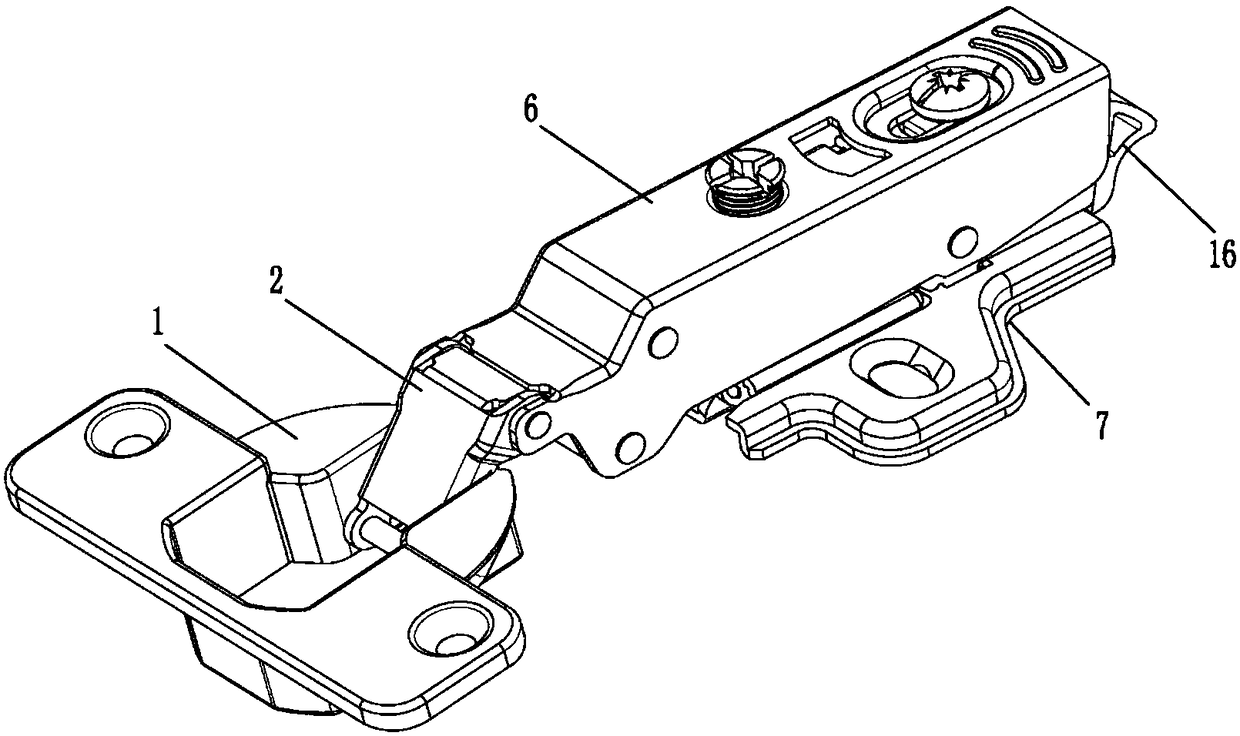

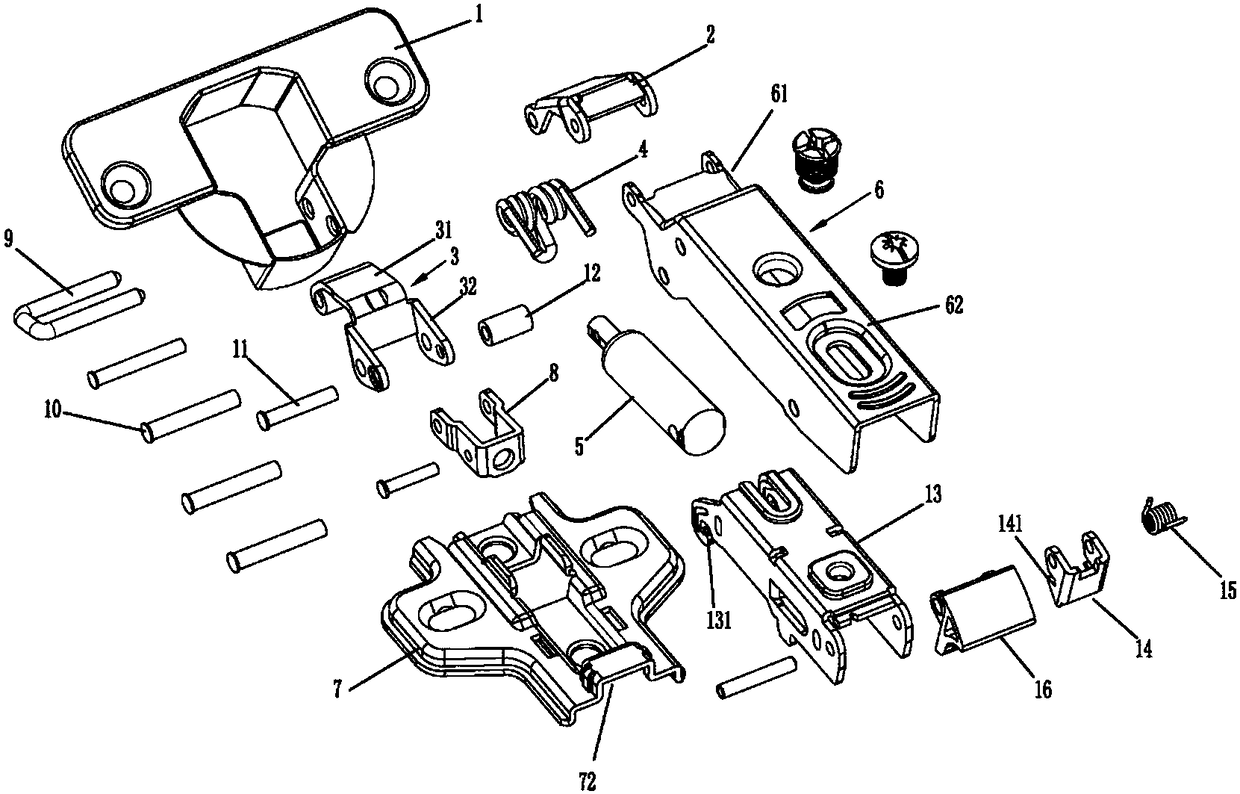

Embodiment 1

[0039] Such as Figure 4~5 As shown, the hinge arm 6 is a straight arm hinge arm, which is suitable for a full cover hinge.

Embodiment 2

[0041] like Figure 7-8 As shown, the hinge arm 6 is a middle-curved hinge arm, which is suitable for half-cover hinges. The left and right sides of connector 8 are provided with guide rail groove 81, and the frame in guide rail groove 81 is provided with guide rod 82 that two ends are fixed on the hinge arm 6, and guide rail groove 81 and guide rod 82 limit the movement track of connector 8, guarantee The damper 5 hinged with the connector 8 performs telescopic movement according to this movement track.

Embodiment 3

[0043] like Figure 9-10 As shown, the hinge arm 6 is a large curved hinge arm, which is suitable for a built-in hinge. The connector 8 includes a first connector 83 and a second connector 84, the front end of the first connector 83 is hinged to the end of the rotating part 32, the end of the first connector 83 is hinged to the front end of the second connector 61, and the second connector 83 is hinged to the front end of the second connector 61. The end of the connecting piece 61 is hinged with the telescopic end of the buffer 5 . The rotation of the rotating part 32 sequentially drives the first connecting part 83 and the second connecting part 84 , and then drives the buffer 5 to perform telescopic movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com