Welding jig suitable for buckling pipe fittings

A technology for welding fixtures and bending pipes, applied in the field of pipe fitting welding and machining, can solve the problems of large space occupation, high cost, long time consumption, etc., and achieve the effect of saving overhead and cost, ensuring welding accuracy, and reducing welding time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

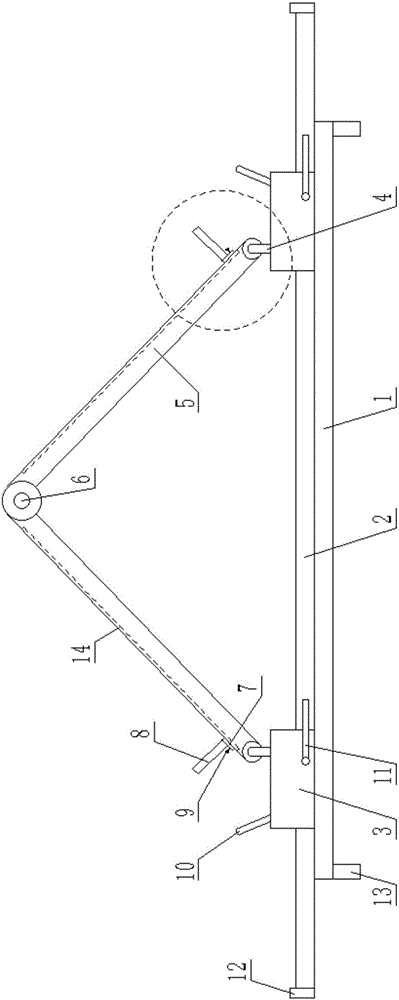

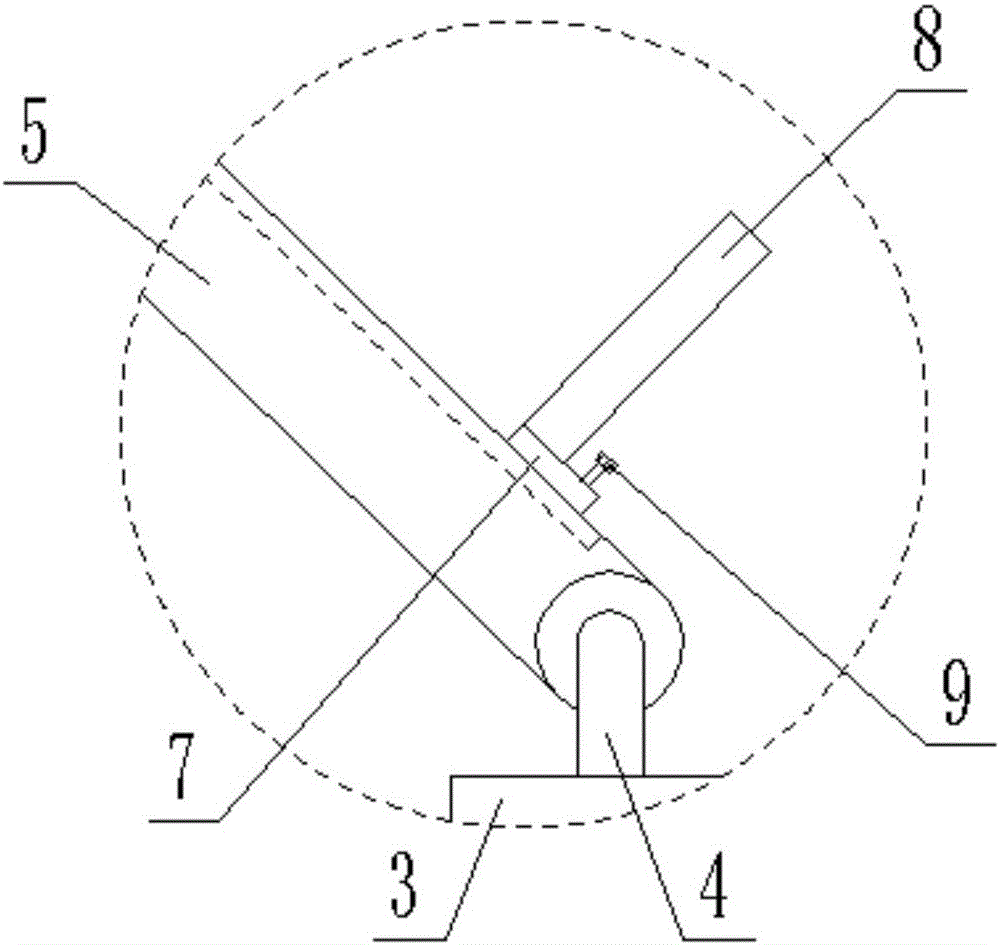

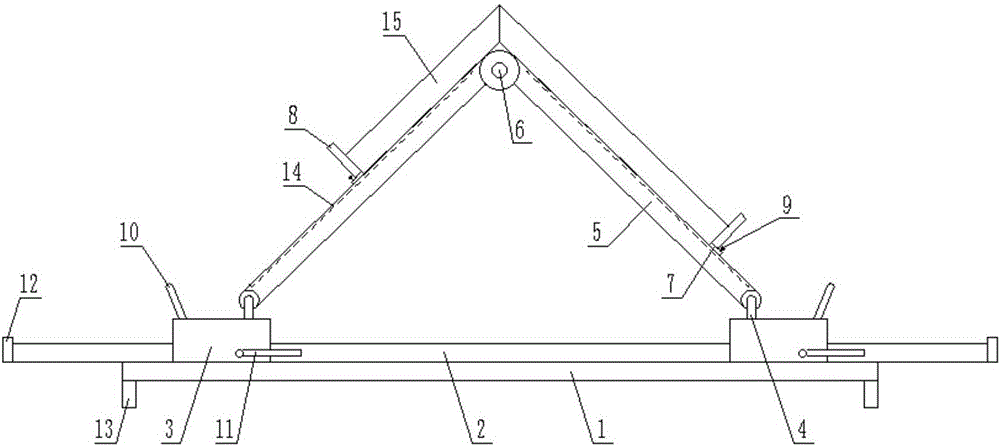

[0023] Example 1: When it is necessary to weld a 90° bent pipe fitting and the lengths of the two pipe bodies 15 are different, the slide seat 3 is pushed or pulled by the handle 10 to slide on the slide rail 2, so that a 90° clip is formed between the two support plates 5 Angle, after the position is adjusted, fix the two sliding seats 3 on the slide rail 2 by rotating the lock 11 to avoid secondary sliding. At this time, place the two pipe bodies 15 to be welded on the support plate 5, loose The locking screw 9 pushes the slider 7 to slide on the chute 14, the lower end of the pipe body is against the baffle plate 8, and the two sliders 7 are pushed at the same time so that the two pipe bodies 15 on both sides are close to each other and spliced together, and then reassembled Tighten the locking screw to fix the slider 7, image 3 In the state shown, tailor welding of the pipe body 15 can be carried out, and the finished product is a bent pipe fitting with an included angl...

Embodiment 2

[0024] Example 2: When it is necessary to weld a 120° bending pipe fitting, push or pull the slide seat 3 to slide on the slide rail 2 through the handle 10, so that a 120° included angle is formed between the two support plates 5, and the position is adjusted by rotating The lock 11 fixes the two sliding seats 3 on the slide rail 2 to avoid secondary sliding. At this time, place the two pipe bodies 15 to be welded on the support plate 5, and loosen the locking screw 9 to push the slider 7 Sliding on the chute 14, the lower end of the pipe body is against the baffle plate 8, and at the same time push the two sliders 7 so that the two pipe bodies 15 on both sides are close to each other and spliced together, and then re-tighten the locking screw to lock the slider 7 fixed Figure 4 In the state shown, tailor welding of the pipe body 15 can be carried out, and the finished product is a bent pipe fitting with an included angle of 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com