Axial flexible deburring spindle

A deburring and spindle technology, applied in the field of machining and manufacturing, can solve the problems of easy damage to workpieces, tool damage, high processing costs, and achieve the effect of easy gas supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

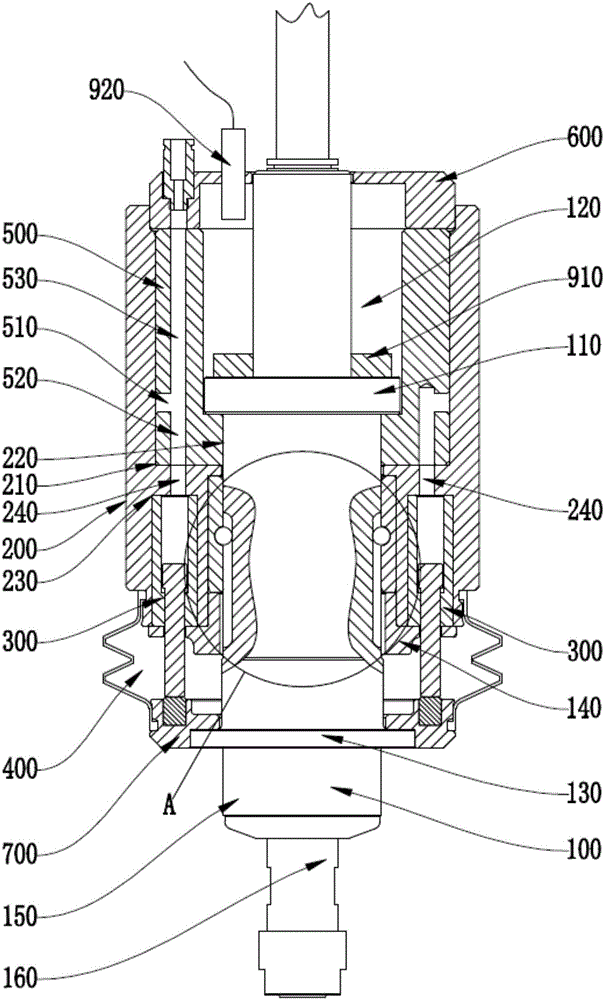

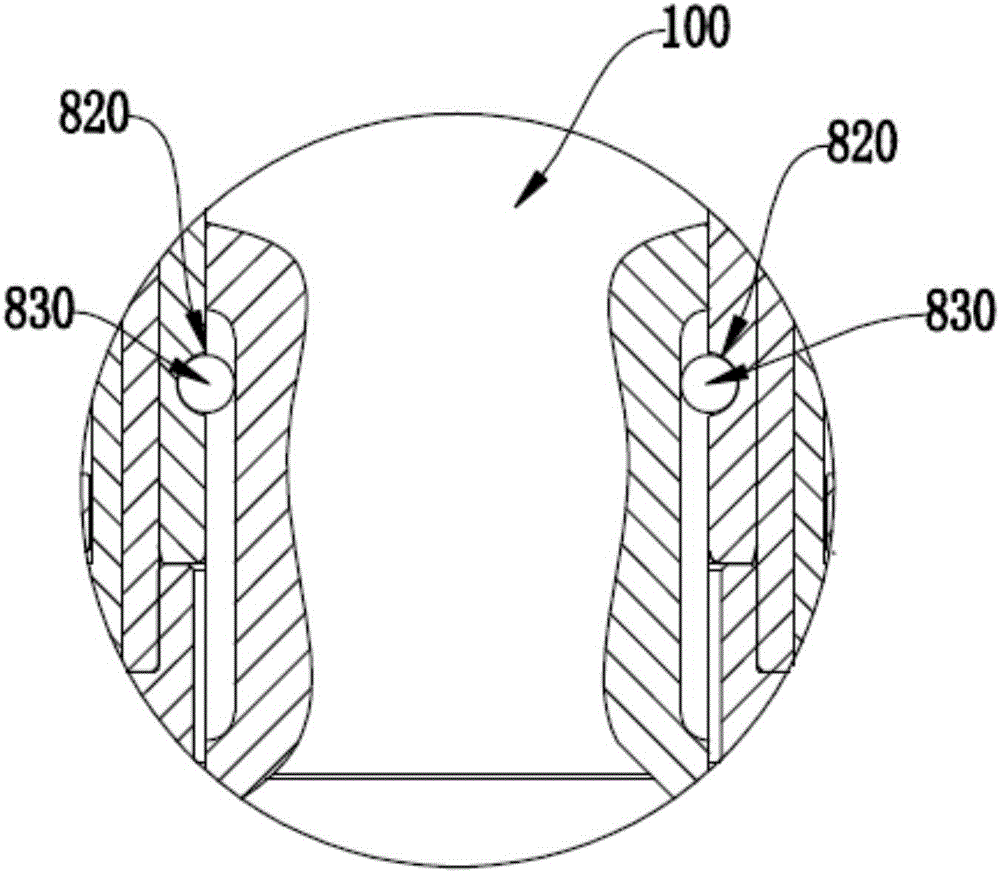

[0022] Such as Figure 1-2 As shown, it includes a main shaft 100, a casing 200, and a cylinder 300; the main shaft 100 includes an outer sliding shaft 150 and an inner working shaft 160, and the inner working shaft 160 is rotatably arranged on the outer sliding shaft 150, and the inner working shaft 160 and the outer sliding shaft 150 are rotationally matched; the main shaft 100 is installed in the main shaft installation hole 220 of the casing 200, and the main shaft 100 slides axially along the main shaft installation hole 220, and at least two of the cylinders 300 are installed in the lower end of the casing 200 in an annular array, and the cylinder 300 acts on the outer sliding shaft 150 at the same time, so that the working end of the inner working shaft 160 can play a flexible and self-adapti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com