Side fixing clamp of heat radiator

A tooling fixture and radiator technology, applied in the field of tooling fixtures, can solve the problems of low clamping efficiency and cumbersome use, and achieve the effect of high clamping efficiency and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

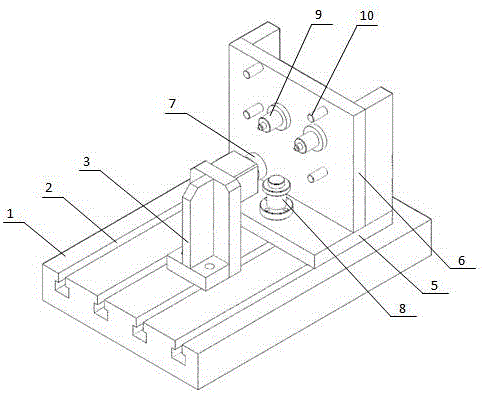

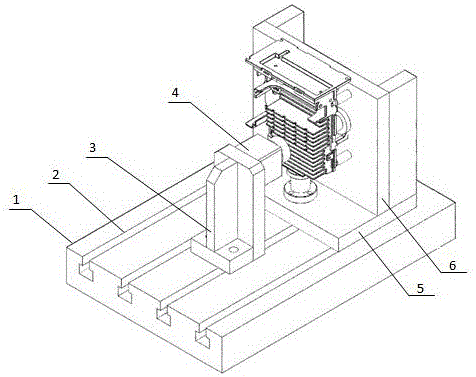

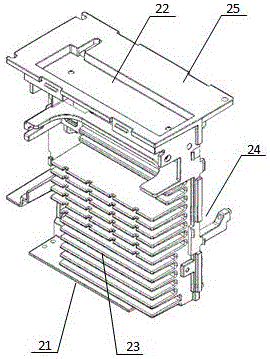

[0013] Such as figure 1 , figure 2 As shown, it includes a bottom plate 1, a positioning seat and a pressing seat 3; the positioning seat includes a base plate 5 and a support plate 6 vertically arranged on the base plate, and the lower part of the base plate 5 is provided with a slider (not shown) that cooperates with the chute 2 on the top of the base plate shown in the figure), the slider and the chute 2 are T-shaped structures, the upper part of the substrate is provided with a support frame 8, and the side of the support plate facing the pressing seat 3 is provided with a positioning pin 9 and a supporting pin 10; The seat 3 is fixed on the base plate, and the upper end of the pressing seat 3 is fixed with a cylinder 4, the piston rod of the cylinder 4 faces the support plate, and the end of the piston rod is provided with a rubber briquetting block 7.

[0014] Among them, the chute 2 is arranged along the length direction of the bottom plate 1, and its length is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com