Torsion spring force measuring tooling

A torsion spring, tooling technology, applied in measuring devices, workpiece clamping devices, force/torque/work measuring instruments, etc., can solve the problems affecting the normal delivery of products, unable to meet the requirements of drawings, unstable installation, etc., to achieve clamping The effect of stability, improving measurement accuracy and improving force measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

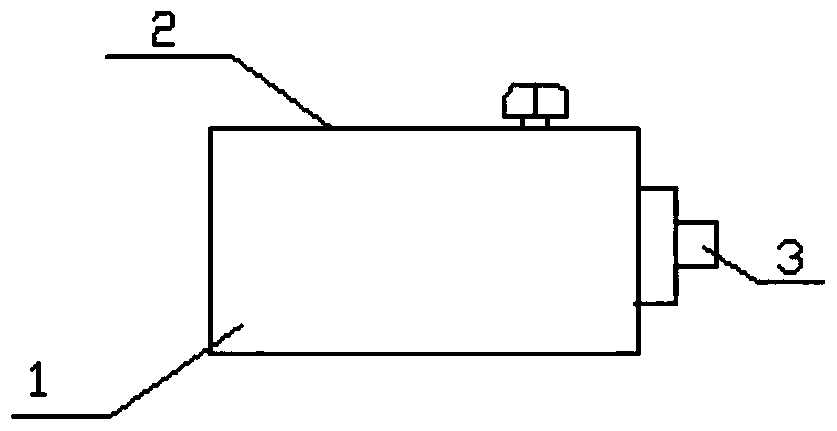

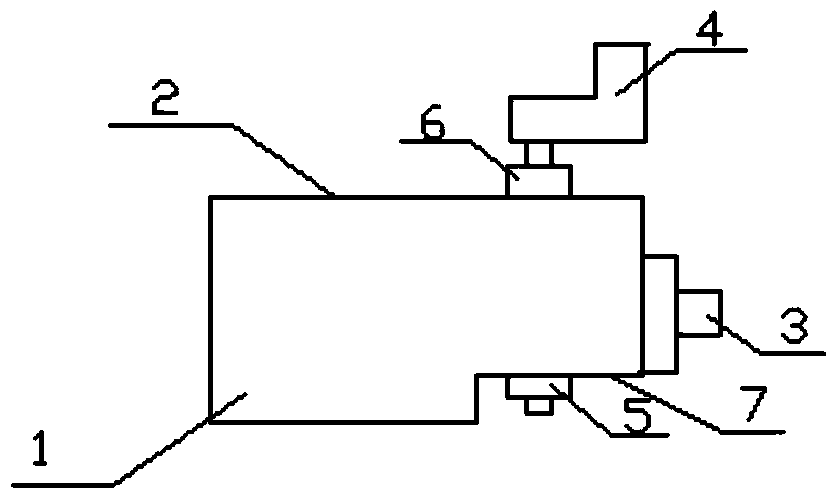

[0013] see figure 2 , torsion spring force measuring tooling, which is composed of connecting end 3, mandrel 1, pressure block 4, nut 5, and protrusion 6, the upper part of the right end of mandrel 1 is provided with protrusion 6, and the lower part of the right end of mandrel 1 is The corresponding part is processed with a concave surface 7, and a through hole is drilled on the protrusion 6 and the concave surface 7. Through the through hole, the end of the pressure block 4 with the bolt passes through the right end of the spring, the protrusion 6 and the concave surface 7 and extends out of the mandrel 1 The lower part of the bottom, and then tighten the end of the briquetting block 4 with the bolt with the nut 5; the tooling is connected with the torsion dynamometer through the connection end 3; the left end of the spring contacts the slide block on the torsion dynamometer. There is a surface contact between the right end of the spring and the upper plane of the boss 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com