Machining process method for complex support parts

A process method and machining technology, which are applied in the field of machining process of complex bearing parts to achieve the effect of improving the machining efficiency and ensuring the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The installation and working methods of the present invention will be described below in conjunction with the accompanying drawings.

[0027] A kind of mechanical processing technology method of complex bearing parts, concrete steps are as follows:

[0028] 1 process: milling

[0029] Milling hexagon: blank size: length: 436, width: 328, thickness: 95

[0030] 2 process: fitter

[0031] Deburring

[0032] 3 process: machining center

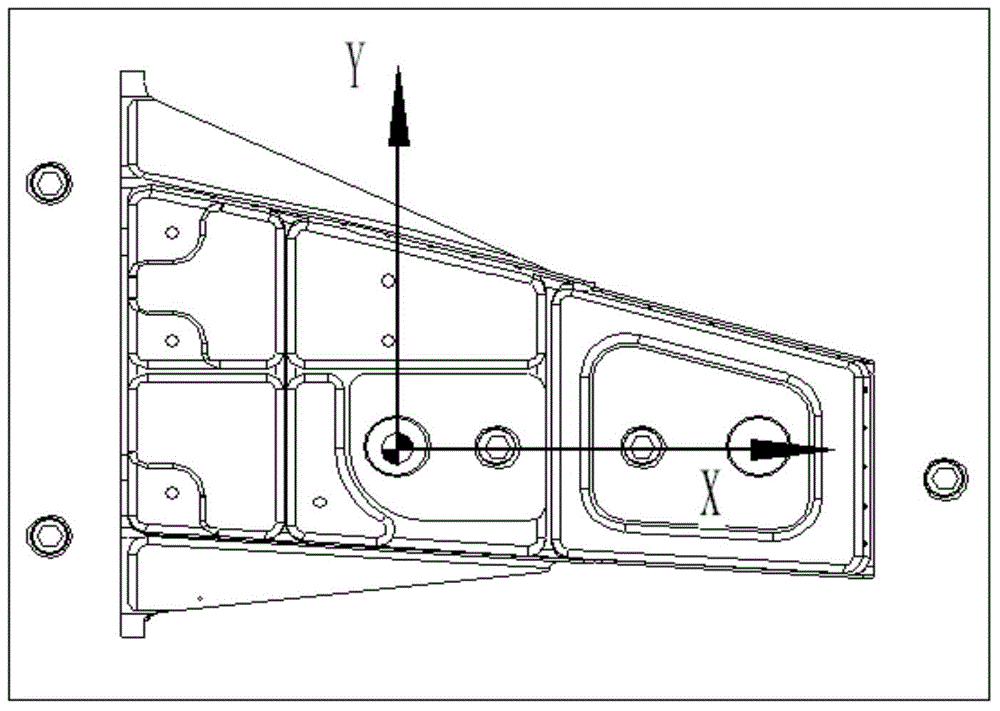

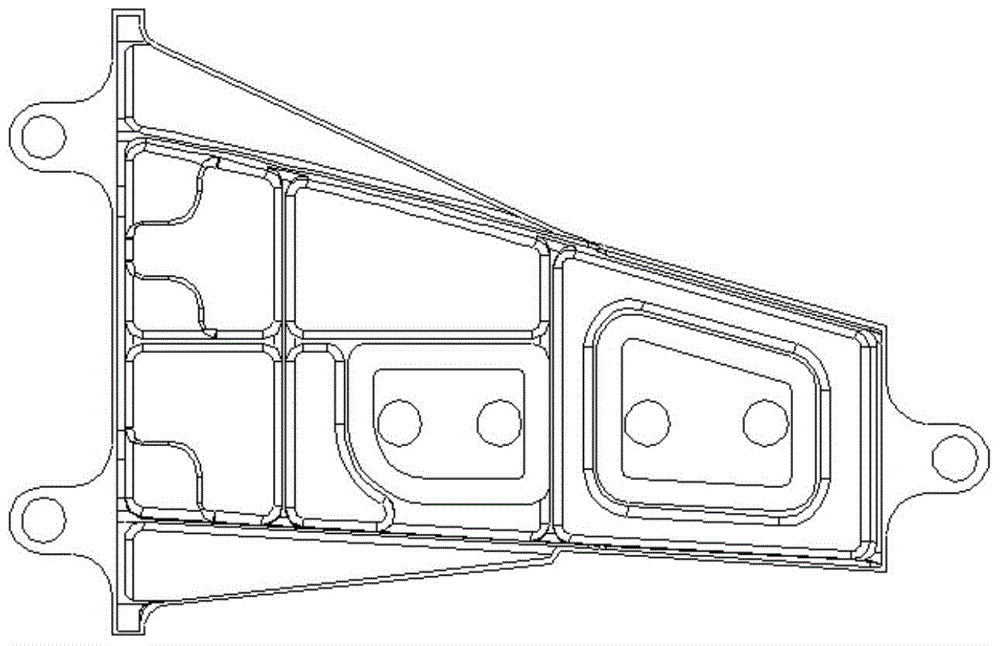

[0033] The CNC machining center is used to process this part, and the machine tool used is UCP800 five-axis CNC machining center. Processing content of the first coordinate system: Z0 value is the lower surface of the blank. The origin is at the center of the positioning hole, and the X-axis is the line connecting the centers of the 2-D20H7 positioning holes.

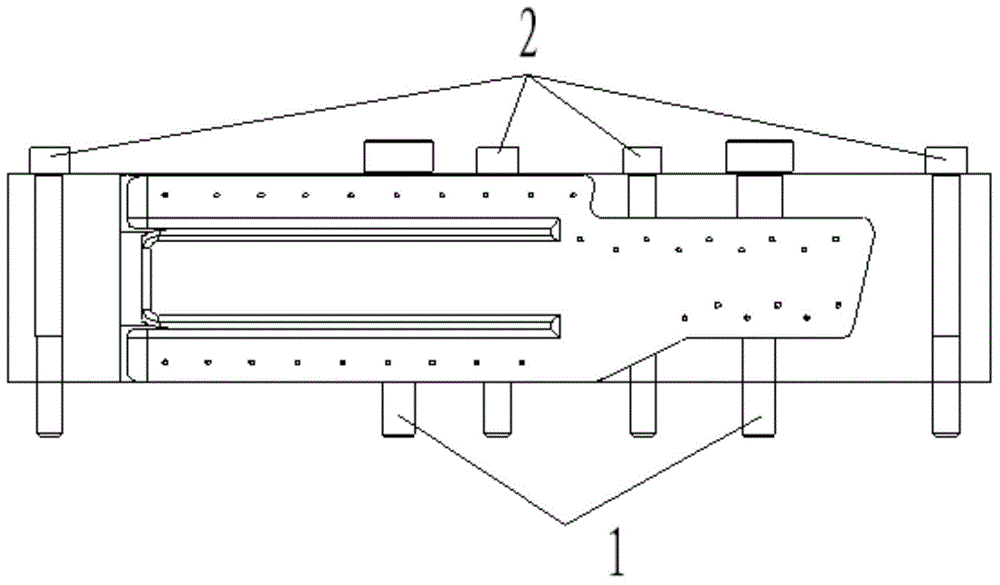

[0034] See the clamping method figure 1 . 1 is two positioning pins, 2 is five countersunk head bolts, see the specific figure Figure 6 .

[0035] First coordinate system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com