Hydraulic braking system

A hydraulic brake and brake master cylinder technology, applied in the direction of brakes, brake transmission devices, foot start devices, etc. Dynamic, precise control, guarantee the effect of pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

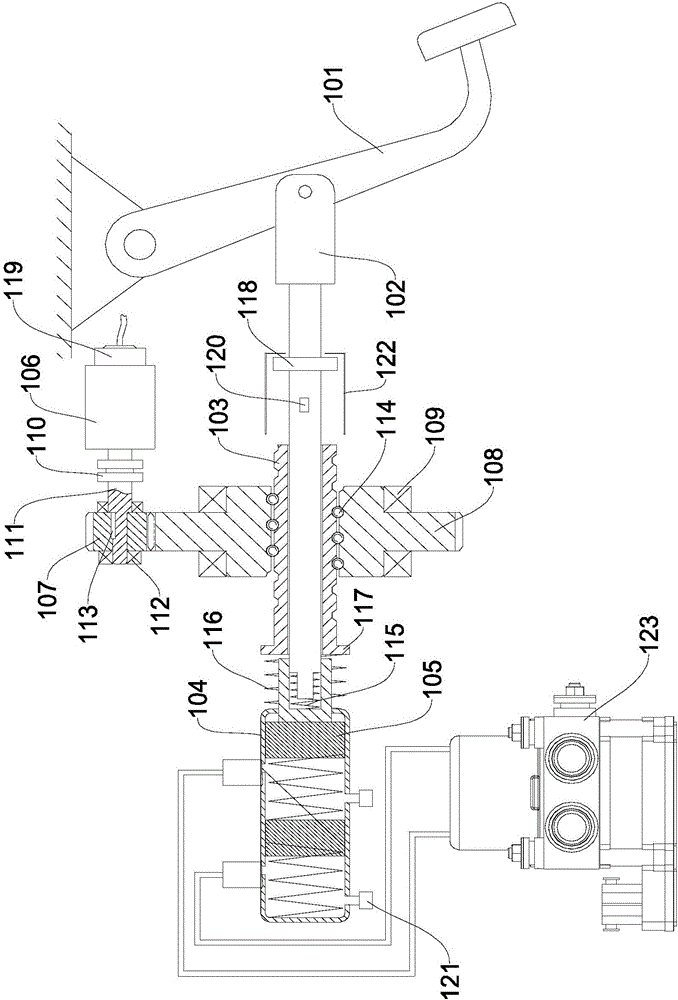

[0032] see figure 1 As shown, the embodiment of the present invention provides a hydraulic braking system, including a pedal mechanism, a servo mechanism and a braking force distribution system; the pedal mechanism includes an input rod 102 and a brake pedal 101, the servo mechanism includes a core tube 103, and the braking force distribution system The system includes a brake master cylinder; the brake pedal 101 is hinged to one end of the input rod 102, and the other end of the input rod 102 is used to push the master cylinder piston 105 of the brake master cylinder to move; the core tube 103 is sleeved on the input rod 102, Used to assist the input rod 102 to move the master cylinder piston 105 of the brake master cylinder.

[0033] Specifically, when the driver steps on the brake pedal 101, the brake pedal 101 can make the input rod 102 move along the axial direction of the input rod 102 itself, so as to push the master cylinder piston 105 to move; The movement of the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com