Multi-section pipe sleeve structure

A technology of segmented tubes and inner tubes, which is applied in the field of multi-section tube sleeve structures, can solve problems such as poor locking effect, potential safety hazards, and inconvenient adjustment, so as to ensure safe use, reliable position locking or telescopic adjustment, and avoid shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

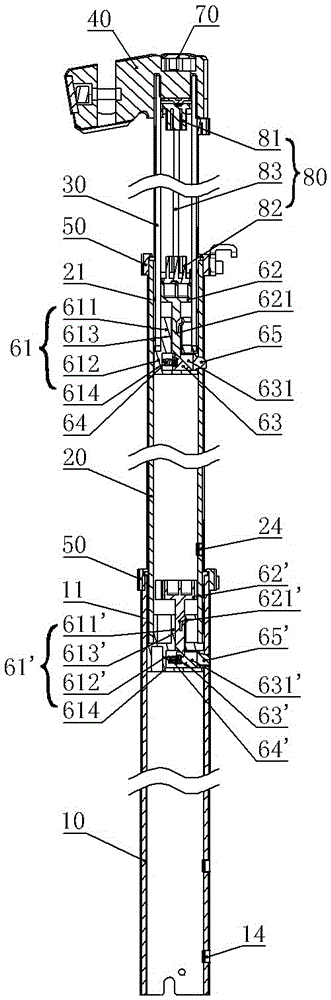

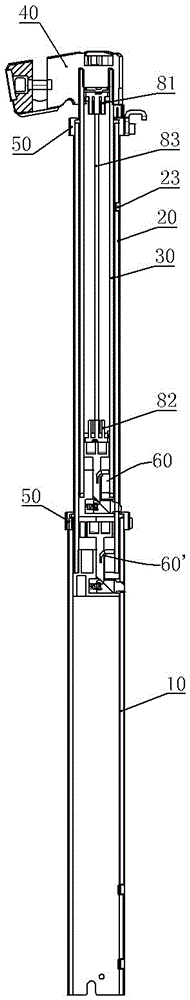

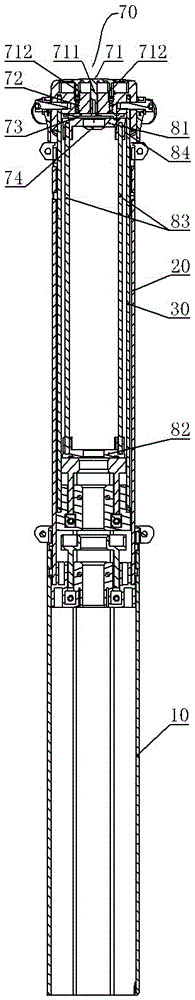

[0023] See Figure 1 to Figure 7 , the multi-section pipe sleeve structure of the present embodiment comprises an outer pipe 10, a middle pipe 20 and an inner pipe 30, the inner circle of the top of the middle pipe 20 and the inner circle of the top of the outer pipe 10 are respectively embedded with inner sliding sleeves 21, 11, and the inner pipe 30 The bottom and the bottom of the middle pipe 20 are inserted into the middle pipe 20 and the outer pipe 10 through the inner sliding sleeves 21 and 11 respectively, and the inner pipe 30 and the middle pipe 20 can move linearly in the middle pipe 20 and the outer pipe 10 respectively. The top of 30 is fixedly connected to the handlebar stand 40, and the top port of the middle pipe 20 and the top port of the outer pipe 30 are respectively provided with opening grooves 22, 12, and clamping adjustment devices 50 are respectively installed at the positions of the opening grooves 22, 12, The outer tube 10 and the middle tube 20, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com