Rear derailleur with continuous multi-gear switching function

A rear derailleur and multi-speed technology, which is applied in the field of rear derailleurs, can solve the problems of difficulty in controlling the position of chain guide components, difficulty in controlling the length of cables, and complicated structure of the rear derailleur, so as to improve the riding performance. Experience, improve riding balance, improve the effect of riding safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

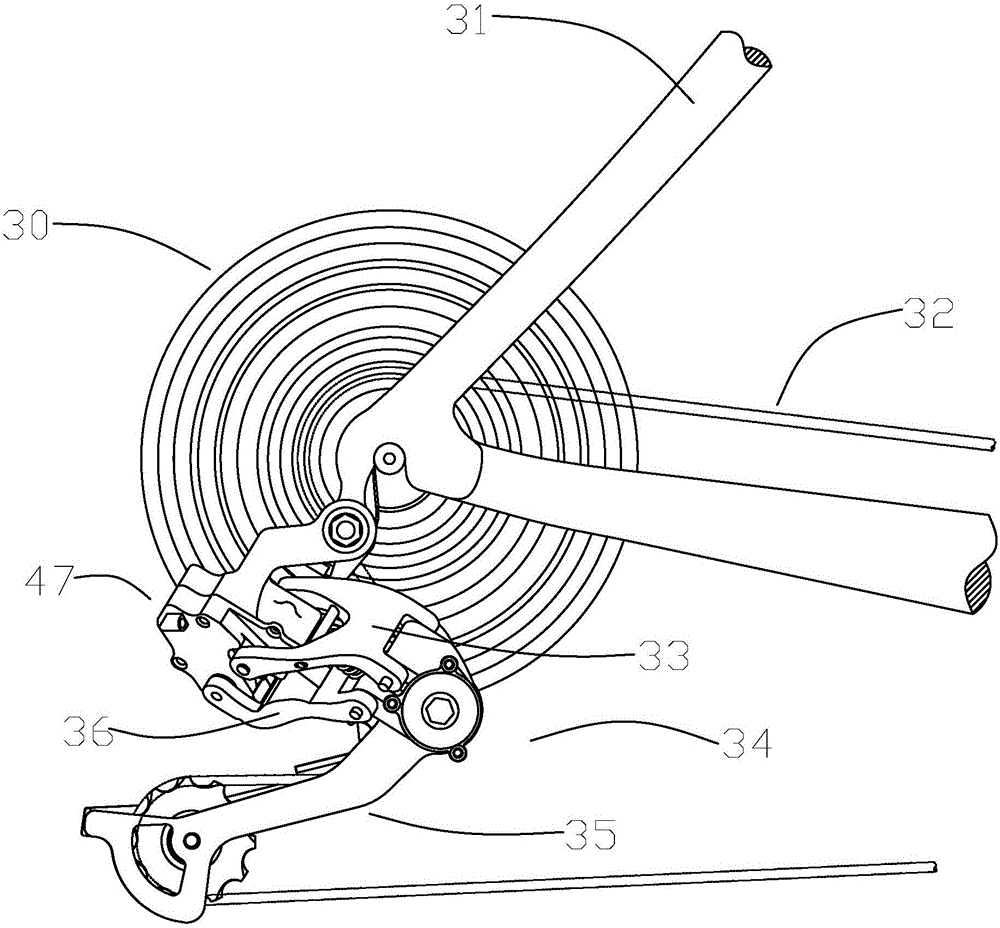

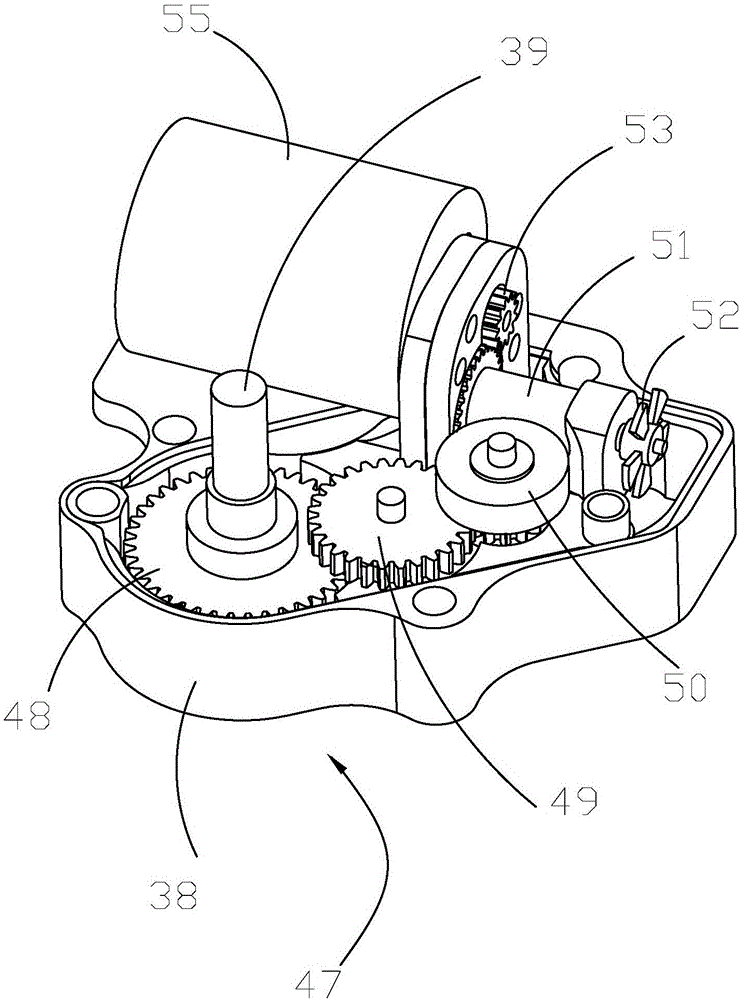

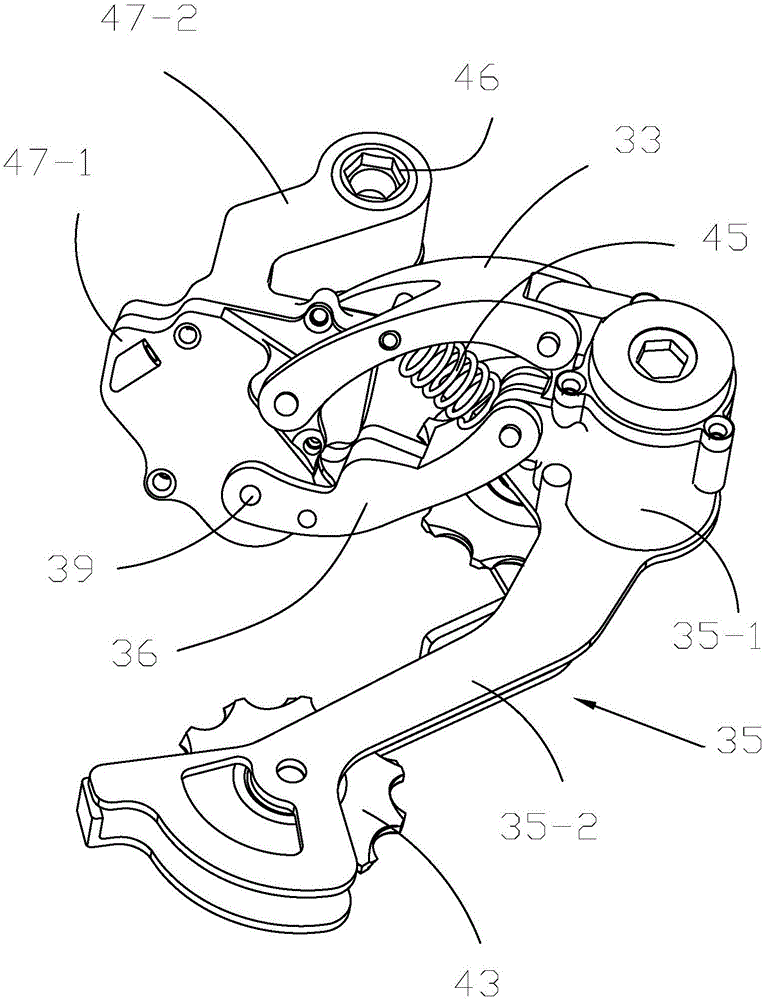

[0032] Example: such as figure 1 As shown, the bicycle includes a vehicle frame 31, a rear sprocket 30 arranged at the rear of the vehicle frame, a chain 32 arranged on the rear sprocket 30, and a rear chain device 34 for adjusting the chain 32 at the position of the rear sprocket 30. Described rear chain device 34 is a rear chain device with continuous multi-gear conversion, which includes:

[0033] Mounting seat 47;

[0034] The four-bar linkage mechanism is arranged on the mounting base 47, and the mounting base 47 constitutes one of the connecting rods;

[0035] a chain guide member connected to the output end of the four-bar linkage mechanism;

[0036] The electronic power drive mechanism 56 is arranged in the mounting seat 47, and is used to control the action of the four-bar linkage mechanism to realize the chain shifting;

[0037] The elastic element 45 is arranged on the four-bar linkage, and is used for absorbing assembly errors and transmitting power.

[0038] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com