Industrial production assembly line optimization device

An optimization device and industrial production technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as assembly line influence and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

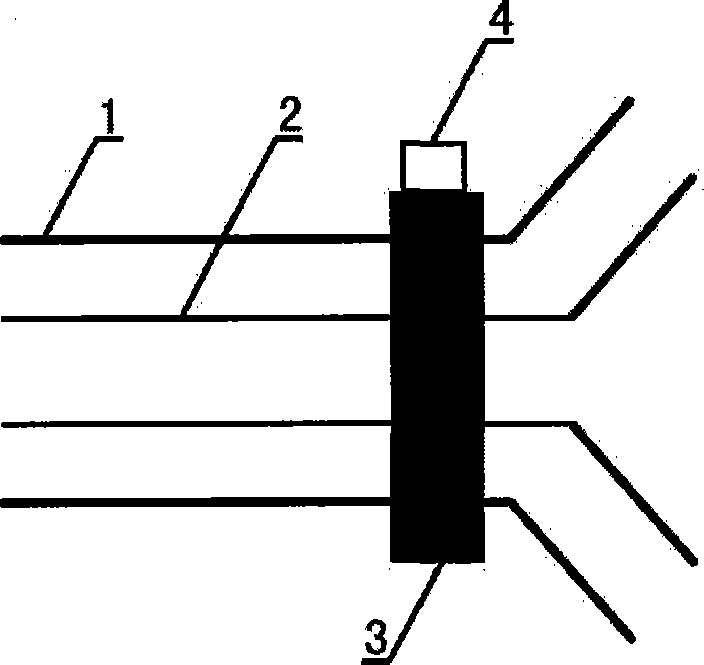

[0013] Embodiment: as shown in the accompanying drawing. The industrial production line optimization device includes an electric conveyor belt [1], a relatively narrow independent conveyor belt [2] is set on the electric conveyor belt [1], the speed of the two conveyor belts is kept in sync, and a detection module is set behind the conveyor belt [ 3] and the hint module [4].

[0014] The industrial production line optimization device is equipped with an electric conveyor belt [1], which can transport products on the working panel of the line.

[0015] The industrial production line optimization device is equipped with an independent conveyor belt [2], which is located in the center of the electric conveyor belt [1], and transports the processed products to the next step.

[0016] The industrial production line optimization device is equipped with a detection module [3], which is located above the electric conveyor belt [1] and can detect products on the entire conveyor belt. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com