High hydrophobic silane paste concrete protecting agent and preparation method thereof

A high hydrophobicity, concrete technology, applied in the field of building materials, can solve the problems of high emulsifier content, high energy consumption and time cost, and complicated preparation process, and achieve simple process, low energy consumption and time cost, and strong waterproof characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

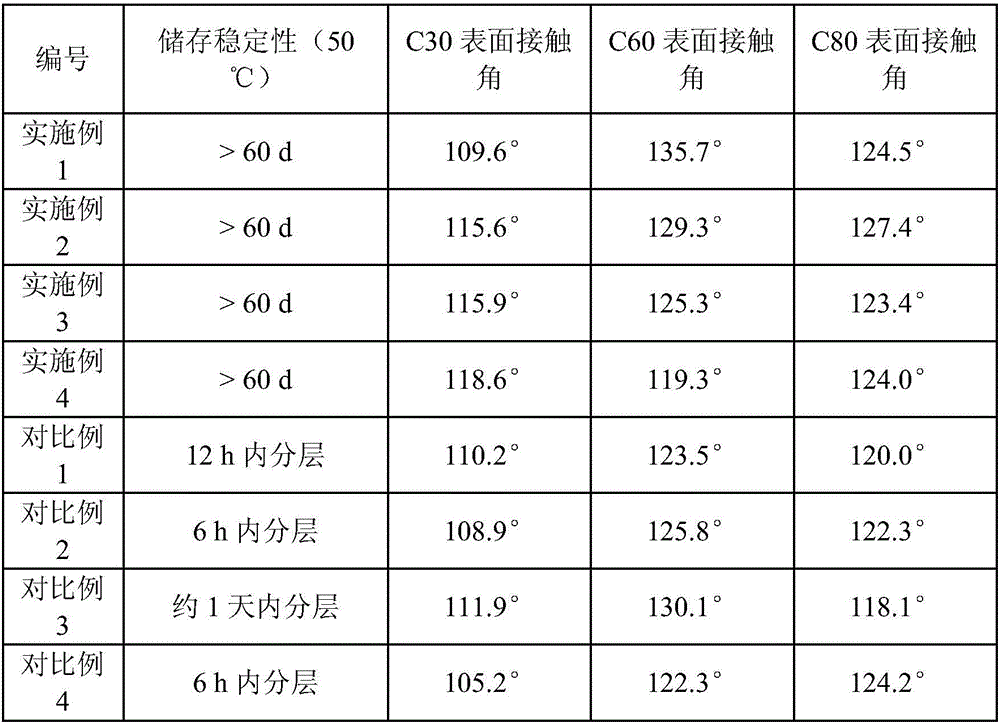

Examples

Embodiment 1

[0025] Add 170g of water, 13.5g of Clariant additive LO 070, 6.5g of Span-80 (average HLB of mixed emulsifier = 9.5) and 8g of modified hydrogenated castor mixed with polyamide wax with a mass fraction of 0.5% into a 2L reactor Sesame oil thickener, disperse and shear at 2800rpm for 10min, stop stirring, add 2g of thickener hydrophobic fumed silica, stir at 500rpm for 3min, then adjust the speed to 3000rpm and disperse for 5min, then adjust the speed to 5000rpm, Add 800g of 823 silane coupling agent dropwise. After the dropwise addition, adjust the rotational speed to 2000rpm and disperse for 5min to obtain a milky white uniform and stable paste.

Embodiment 2

[0027] 15g of Clariant additive LO 070, 5g of Span-80 (average HLB of mixed emulsifier=10.1) were used, and the others were consistent with Example 1.

Embodiment 3

[0029] Add 210g of water, 18g of Clariant additive LO 070, 2g of Span-80 (average HLB of mixed emulsifier=11.2) and 7g of modified hydrogenated castor oil mixed with polyamide wax with a mass fraction of 1.5% in a 2L reactor. Thickener, disperse and shear for 10min at a speed of 2800rpm, stop stirring, add 3g of thickener hydrophobic fumed silica, stir for 3min at a speed of 500rpm, then adjust the speed to 3000rpm and disperse for 5min, then adjust the speed to 5000rpm, add dropwise 770g of 1213 silane coupling agent, after the dropwise addition, adjust the speed to 2000rpm and disperse for 5min to obtain a milky white uniform and stable paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com