Novel environment-friendly track

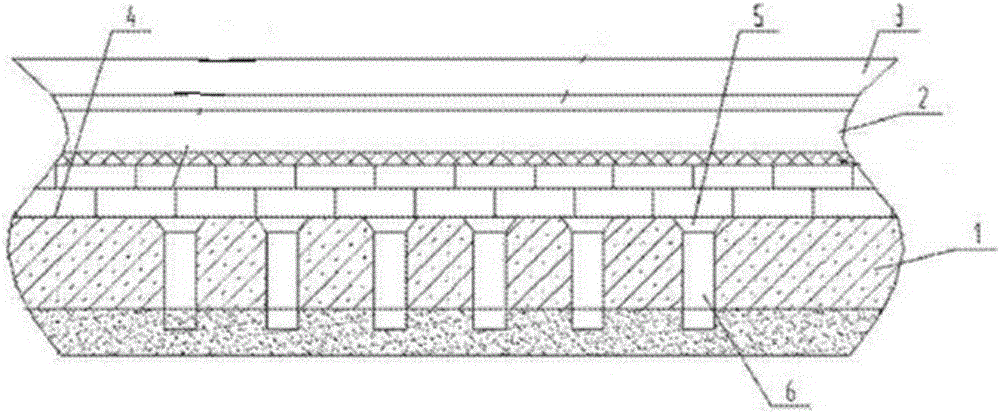

An environmentally friendly and runway technology, applied in roads, roads, buildings, etc., can solve the problems of builders and users, environmental pollution, performance differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

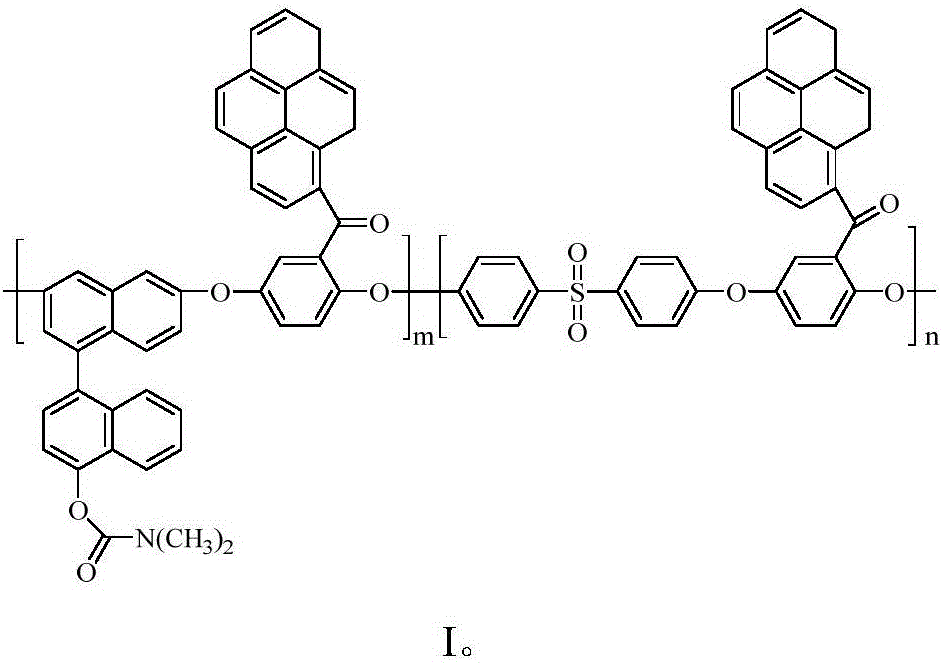

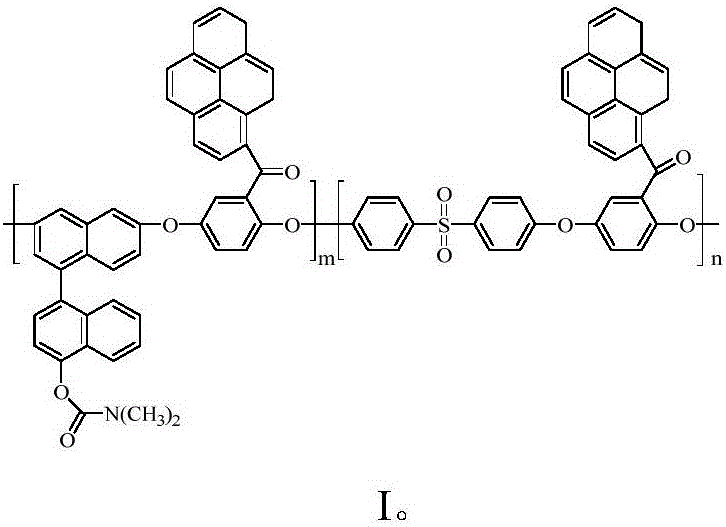

[0044] Embodiment 1: the preparation of formula I polymer

[0045] Under a nitrogen atmosphere, 15.0 mmol of 2-(N,N-dimethylaminoesteryl)-3,6-difluoro-8-(1'-naphthyl)-naphthalene, 4,4'-dichlorobenzene 8.0mmol of sulfone, 25mmol of 1-(2,5-dihydroxybenzoyl)pyrene, 30mmol of anhydrous potassium carbonate, 60ml of N,N-dimethylacetamide, and 30ml of toluene were mixed in a reaction vessel and heated in an oil bath to 150°C, water was separated for 4 hours, the toluene was distilled off, the temperature was raised to 190°C, and the reaction was carried out overnight. Slowly pour the reaction solution into 500ml of deionized water to obtain a white strip-shaped polymer, change the water, keep the temperature at 80°C, boil in water three times, each time for 6 hours, dry it, and then dry it under vacuum at 100°C for 24 hours to obtain a white fibrous polymer. Formula I polymer, yield 91.8%. where M w is 2.88×10 5 ,M n 0.75×10 5 , the molecular weight distribution index is 3.84. ...

Embodiment 2

[0048] Embodiment 2: the toxicity test of formula I polymer:

[0049] The PPARδ activity of the inventive polymer represented by formula I was confirmed by transfection assay. In addition, selectivity for the PPAR subtypes PPARα and PPARγ was also examined. Cytotoxicity was tested by MTT assay, and in vivo activity was studied by animal experiments.

[0050] CV-1 cells were used in this assay. The cells were inoculated into 96-well plates containing DMEM supplemented with 10% FBS, DBS (non-specific bovine serum, defatted) and 1% penicillin / streptomycin, and incubated at 37°C, 5% CO 2 cultured in an incubator. Experiments were performed following the steps of inoculation, transfection, sample application and confirmation. Specifically, CV-1 cells were seeded into a 96-well plate (5000 cells / well), and transfected 24 hours later. Full-length PPAR plasmid DNA, reporter DNA to confirm PPAR activity due to luciferase activity, β-galactosidase DNA to provide information on tran...

Embodiment 3

[0056] Embodiment 3: the preparation of runway material

[0057] (1) with 85 kilograms of formula I polymer, 2 kilograms of N-cyclohexyl-2-benzothiazole sulfenamide, 2 kilograms of amino silicone oil, 3 kilograms of DL-1000, 0.05 kilograms of antioxidant 1010, 0.1 kg of phenyl o-hydroxybenzoate is fully mixed, stirred evenly, and heated to about 90°C;

[0058] (2) add 3 kilograms of talcum powder and 0.5 kilograms of 4.4 '-bis(2.2-dimethylbenzyl) diphenylamine, stir;

[0059] (3) Grinding the above-mentioned materials to a particle size below 400 mesh with a colloid mill;

[0060] (4) Continue to heat up to about 100°C, and dehydrate for 4 hours at a vacuum degree below 0.06MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap