Cleaning machine for textile machine

A technology for textile machinery and cleaning machines, applied in the field of cleaning machines, can solve the problems of unintentional collision of rubber blowing nozzles, loss of cleaning function of cleaning machines, blockage of filter screens, etc., so as to improve air conditions in workshops, and be beneficial to spinning production and cleaning. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

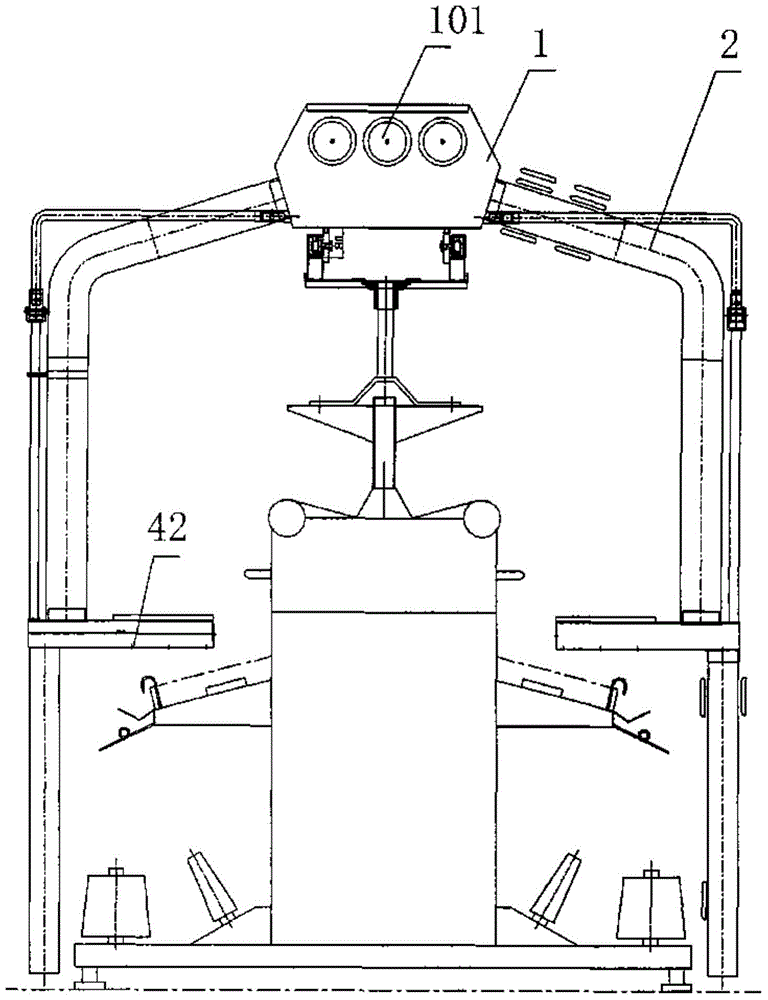

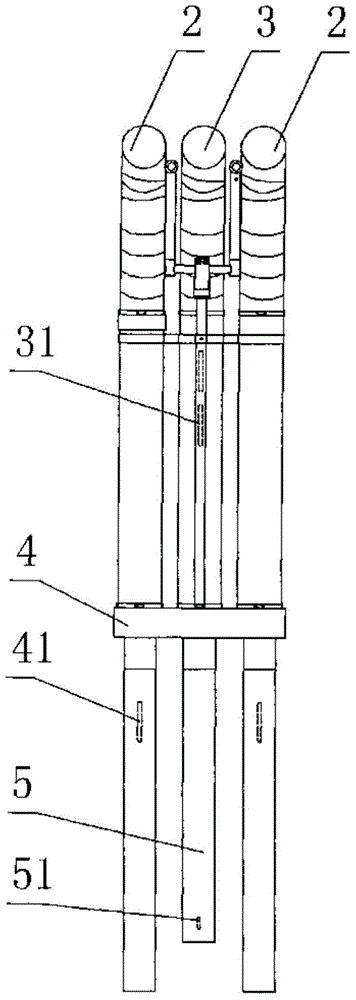

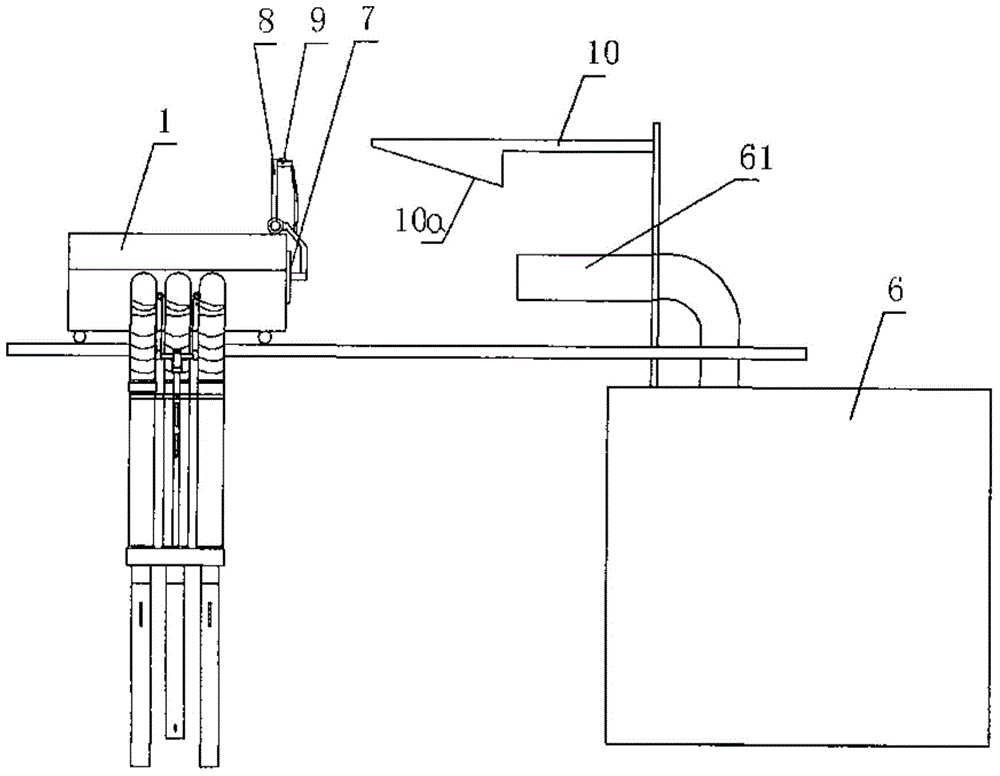

[0023] Example: see Figures 1 to 6 As shown, a textile machinery cleaning machine includes a cleaning main machine 1, a blowing pipe 2 and a suction pipe 3 are arranged on the cleaning main machine 1, a blowing box 4 is fixed on the blowing pipe 2, and a blowing box 4 is formed on the blowing box 4 to directly face The blowing hole 41 of the textile machinery needs to be cleaned, and the blowing hole 41 is connected with the blowing pipe 2. The blowing box 4 is formed with a suction hole 42 matched with the blowing hole 41, and the suction hole 42 is connected with the suction pipe 3.

[0024] The ground suction pipe 5 is fixed on the blowing box 4 and communicated with the suction pipe 3, and the ground suction pipe 5 is provided with a cotton suction port 51 in the air of the ground suction pipe.

[0025] The air suction pipe 3 is provided with a cotton suction opening 31 in the air.

[0026] The air suction hole 42 is arranged to face the working surface of the textile ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com