Asphalt pavement pressure generator embedding method

A pressure generator, asphalt pavement technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, road, etc. Problems such as lack of generator burying technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

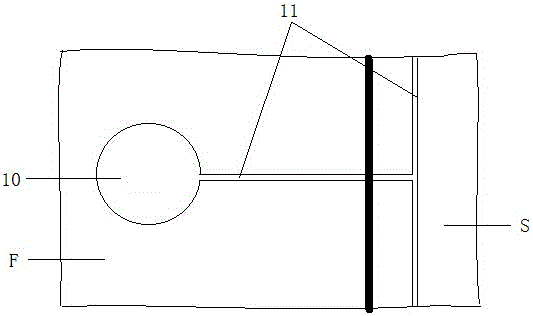

[0056] Embodiment 1: The asphalt pavement pressure generator embedding method of the present invention is implemented in a certain two-way four-lane expressway pressure generating circuit section, the project scale is 200m expressway lane, and a commercially available cylindrical pressure generator with a diameter of 29.5cm and a height of 8cm is adopted .

[0057] The specific operation method and steps of the asphalt pavement pressure generator embedding method of the present embodiment are as follows:

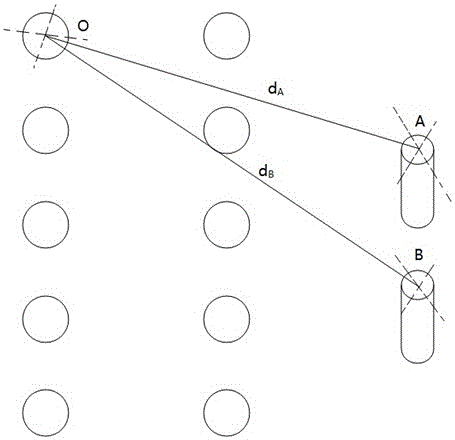

[0058] (1) Basic point positioning

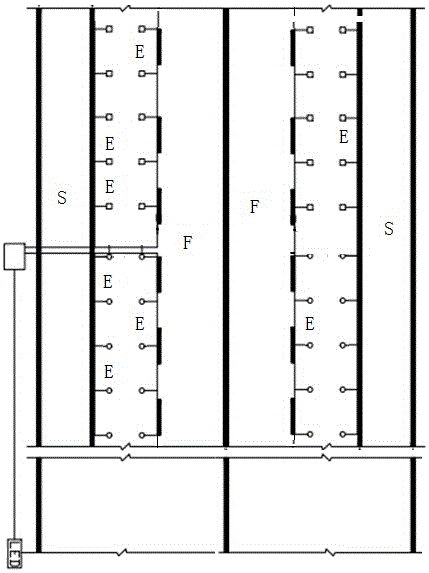

[0059] (1.1) Select a road section suitable for burying the pressure power generation system, and design the buried layout and wiring of the pressure generators in the road section. The pressure generators are arranged along the vertical and horizontal lines of the road, and the vertical layout is arranged at an equidistant distance of 2.5m. Two roads are installed in each horizontal row of each lane. The pressure generator, the wires of...

Embodiment 2

[0096]Embodiment 2: The asphalt pavement pressure generator embedding method of the present invention is implemented in a certain two-way six-lane expressway pressure generator section, and the project scale is 500m expressway lane, adopting a rectangular pressure generator with a length, width, 30cm×30cm, and a height of 8cm . The specific operation method and steps are as follows:

[0097] (1) Basic point positioning

[0098] (1.1) When the pavement of the lower layer of the road section is completed but the surface layer of asphalt mixture is not paved, the pressure generator embedding layout and wiring design of the road section shall be carried out first. Two pressure generators are arranged in each horizontal row in each lane (arranged on both sides with high frequency of wheel overrun), and the wires of the pressure generators enter the road shoulder from the pressure generator to the outside of the lane, and then gather and connect to the peripheral lines;

[0099] (...

Embodiment 3

[0129] Embodiment 3: The embedding method of the asphalt pavement pressure generator of the present invention is implemented in a certain two-way six-lane expressway pressure generating circuit section, the project scale is 300m expressway carriageway, and a commercially available electric generator with length × width 28.5mm × 26.5mm and a height of 8mm is adopted. Rectangular pressure generators are arranged longitudinally and transversely along the road with a longitudinal interval of 4m. The specific operation method and steps of pressure generator embedding are the same as in Example 2. After the embedding step is completed, let it dry naturally for 18 hours, then add an epoxy resin anti-skid coating to the road surface in the entire pressure generator embedding area, and then dry it naturally for 7 hours. After the epoxy resin is cured, the entire construction process is completed.

[0130] In the present embodiment, the pressure generator is embedded with a pit depth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com