Steel box girder arc-shaped U rib installing and positioning method

A technology for installation and positioning and steel box girders, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in meeting construction schedules, large manpower and material resources, etc., and achieve the effect of improving work efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

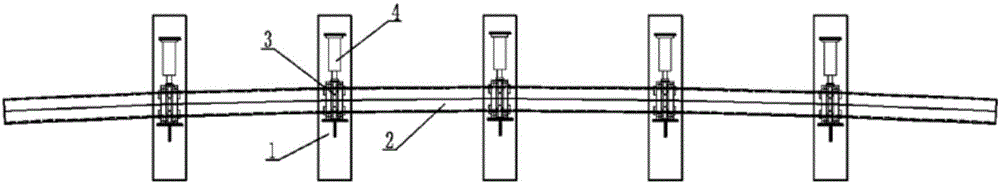

[0030] The invention provides a method for installing and locating arc-shaped U-ribs of steel box girders, which includes the following steps:

[0031] S1, draw a line:

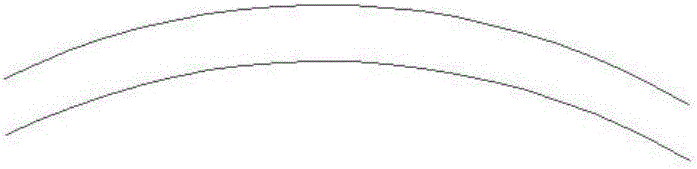

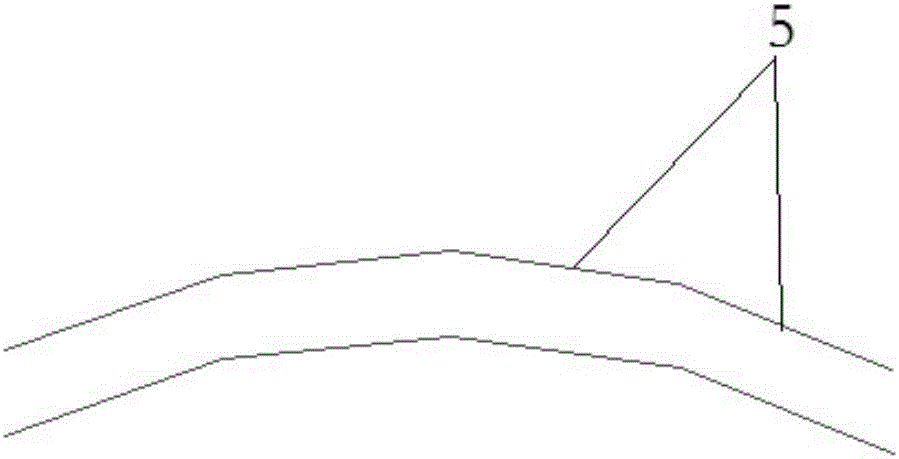

[0032] Set the marking work platform in the area where the U rib of the steel box girder is to be installed. After leveling, draw the line from the center to both sides; Standard curved curves, such as figure 2 As shown, the standard arc curve is equally divided, such as image 3 As shown, the two ends of each equally divided arc segment are connected into a straight line segment 5, and the drawn line is an approximate curve formed by the straight line segment 5;

[0033] At the same time, make a partition-like punching mark on the marking work platform (in order to facilitate the later partition assembly, the center of the partition and longitudinal web needs a punching mark whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com