Patents

Literature

45results about How to "Play a role in strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol substituting beverage and preparation method thereof

The invention relates to alcohol substituting beverage and a preparation method thereof. The preparation method includes steps of placing water, expanded sea cucumber, dry red pepper, ginger, chrysanthemum, wolfberry and red dates into a marmite; simmering for 15-30 minutes; filtering; pouring juice into a container with honey after the juice is cooled down to the temperature of 45 DEG C to 55 DEG C; and blending. The alcohol substituting beverage is suitable for drinking after being heated in winters and being cooled down in summers, has effects of nourishing tonic in winters and relieving summer-heat, is particularly suitable for drivers, and has synergistic effects of invigorating stomach, improving eyesight, keeping fit and refreshing.

Owner:许传平

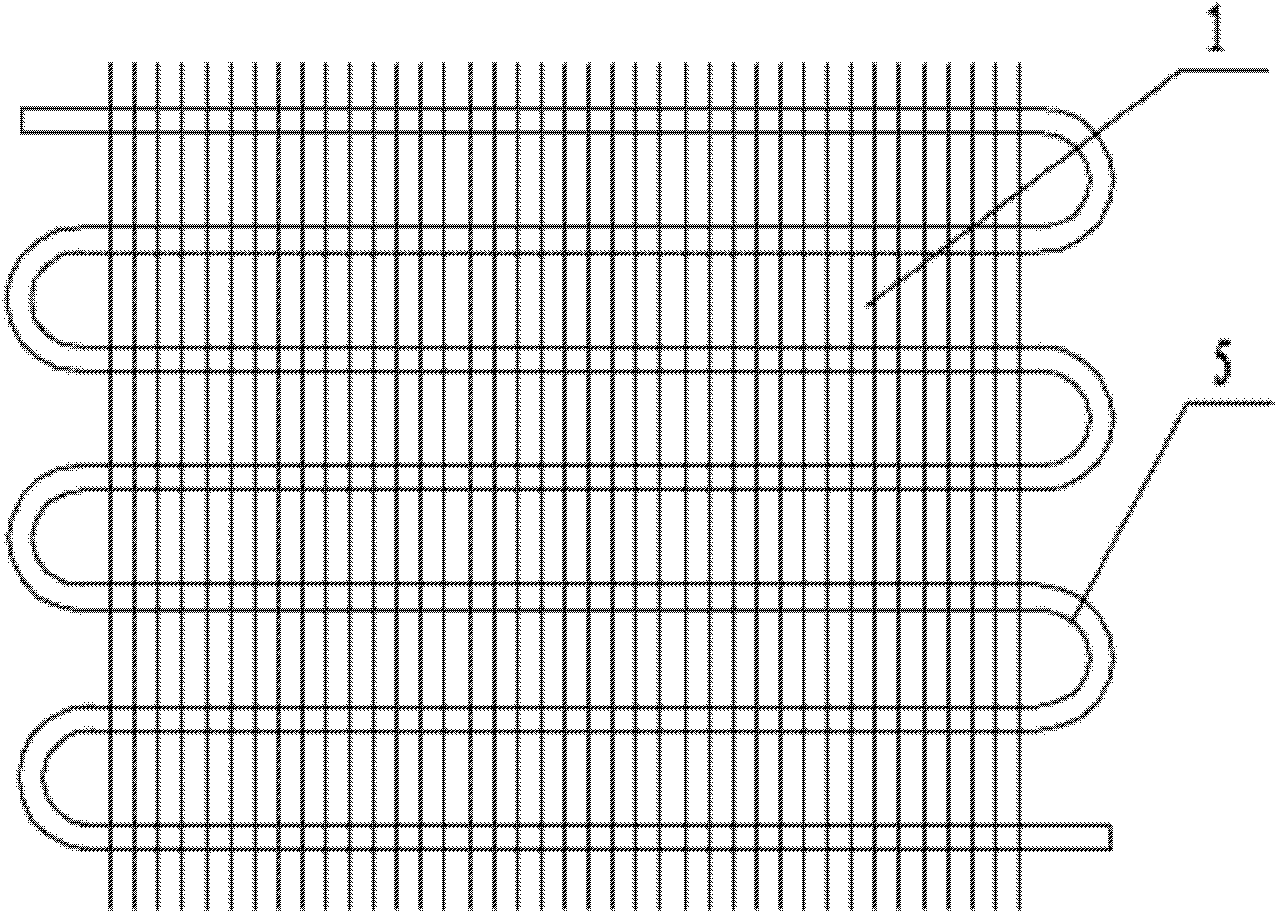

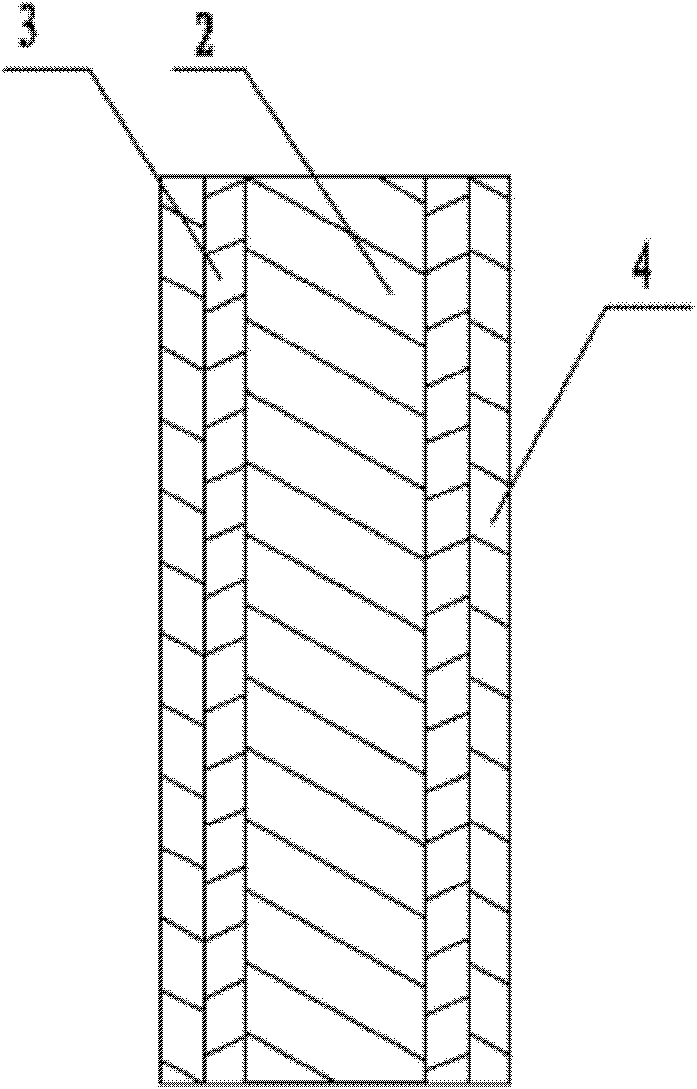

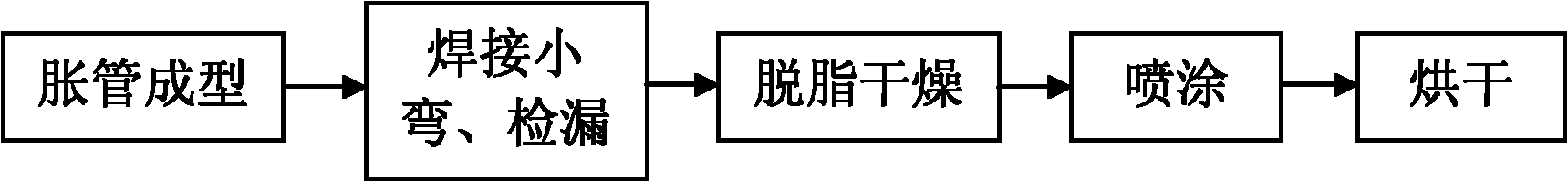

Titanium heat exchanger for air conditioner and processing method thereof

ActiveCN102192620ALong-term stable antibacterial and mildew removal effectGood for healthEvaporators/condensersCoatingsTitanium coatingPlate heat exchanger

The invention discloses a titanium heat exchanger for an air conditioner, and a processing method thereof. The titanium heat exchanger comprises a heat exchange pipe and cooling fins. The surface of each cooling fin is provided with a TiO2-containing titanium coating, the titanium coating contains CuO and Ag2O, the mass percentage of CuO is 10%-15%, and the mass percentage of Ag2O is 10%-15%. When the light is sufficient, the titanium coating of the heat exchanger is decomposed under the photochemical catalysis of the ultraviolet light, and various organics attached on the titanium oxide surface are removed. When the light is insufficient, titanium oxide also can make the internal electrons excited to generate hydroxyl atomic groups and hydrogen peroxide under the action of nano silver and nano copper, so as to decompose the organics. Therefore the heat exchanger has long-term and stable effect of anti-bacterial and mildew-removal.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

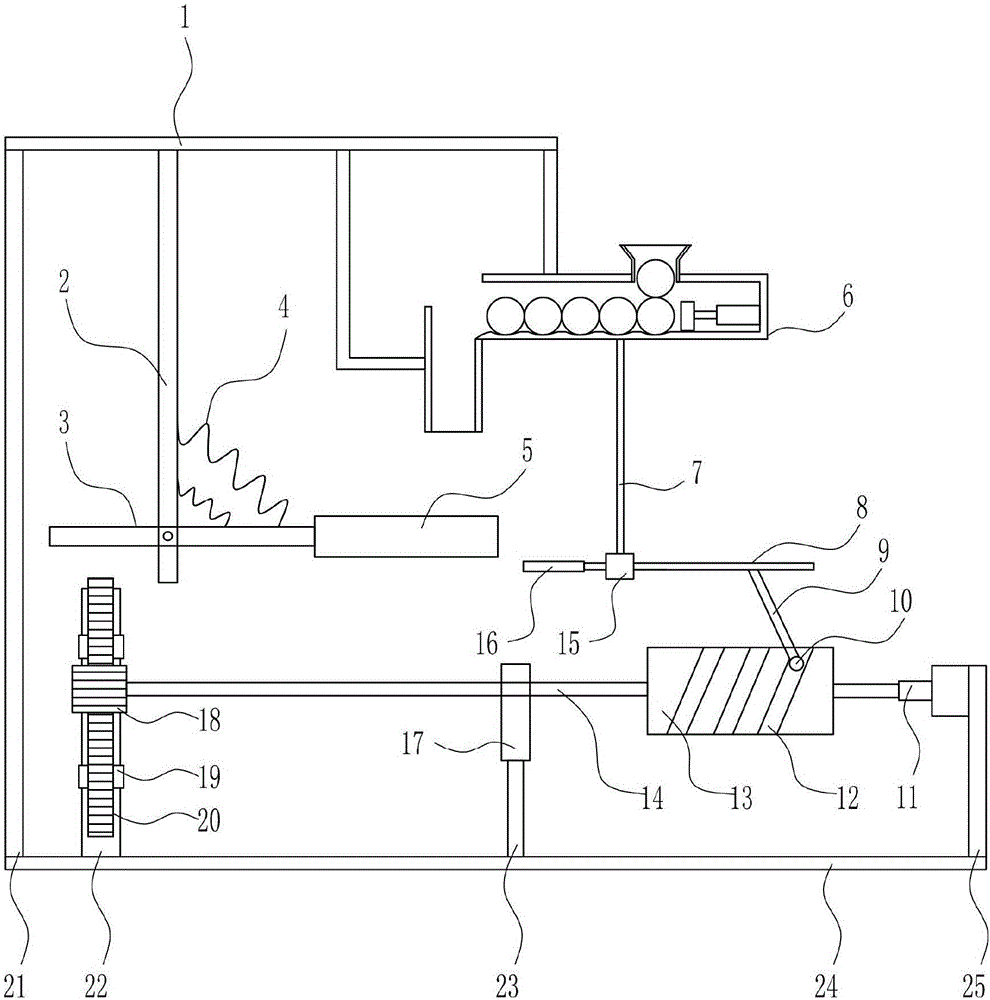

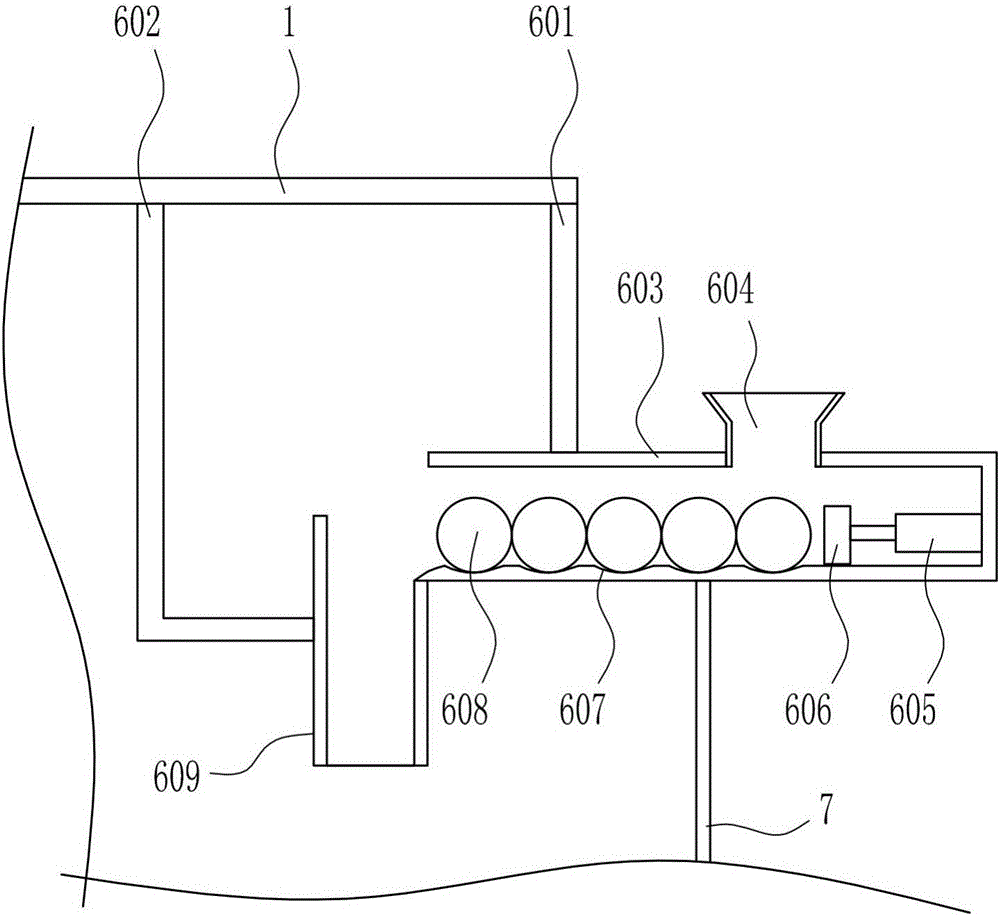

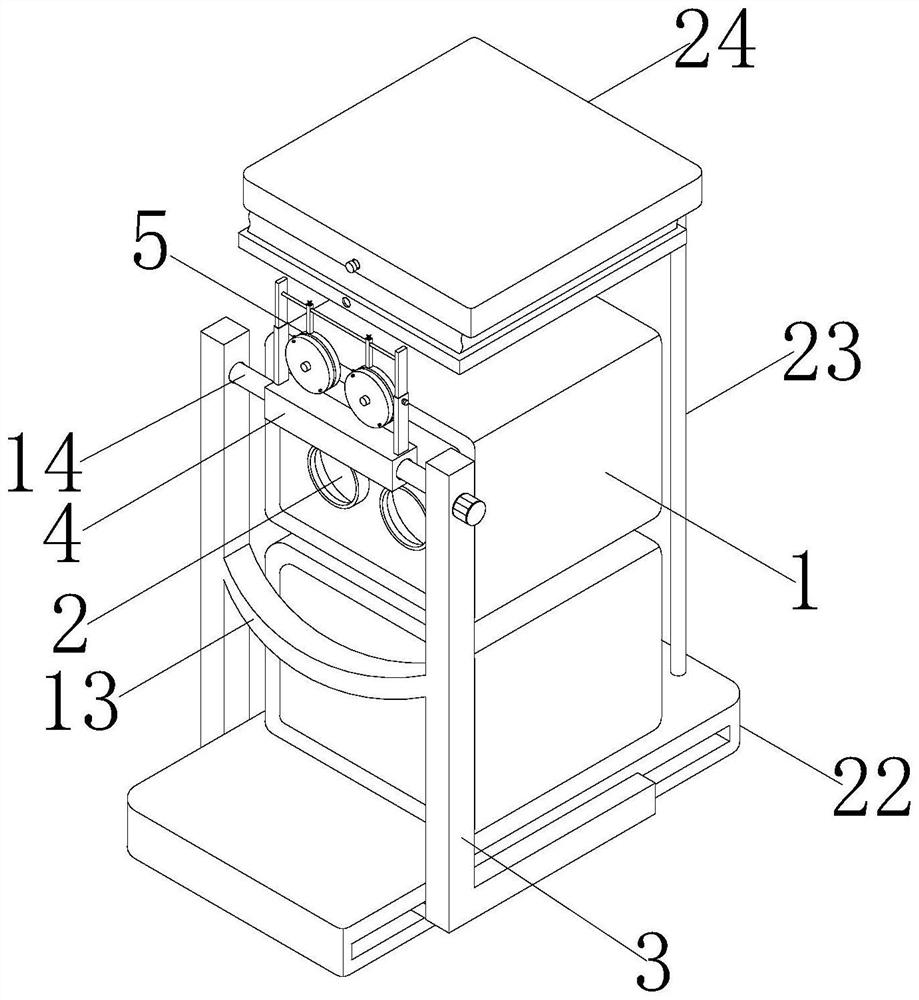

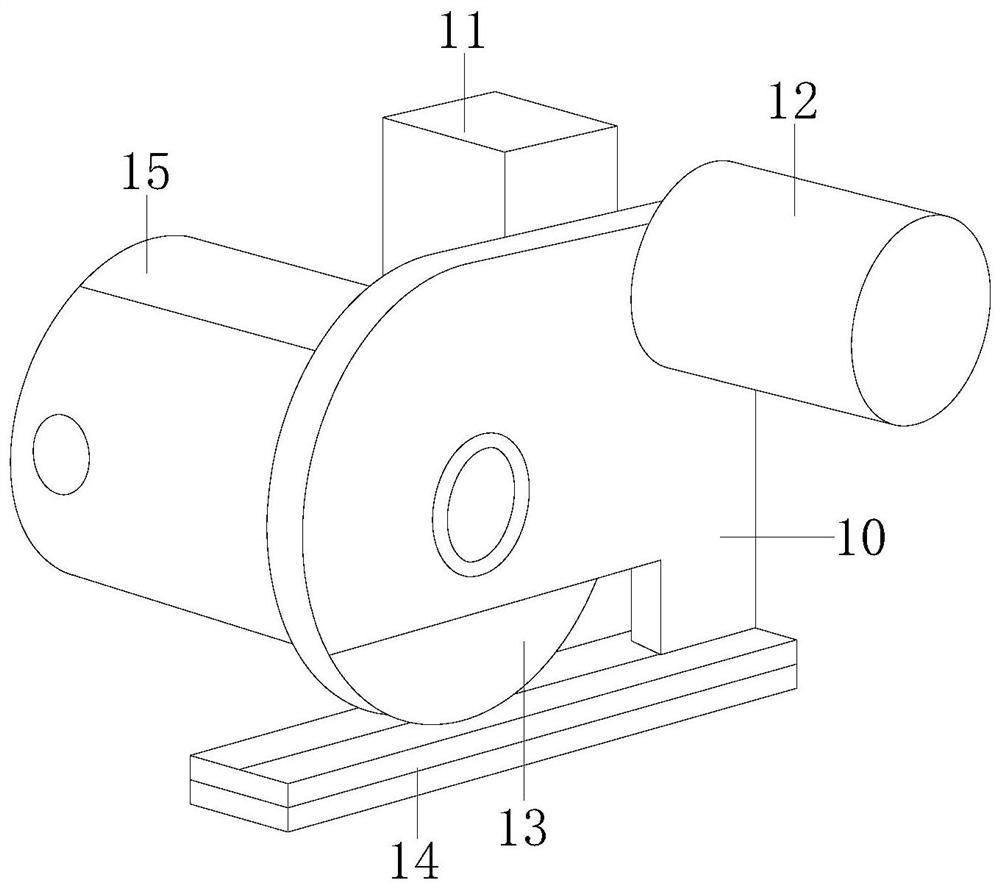

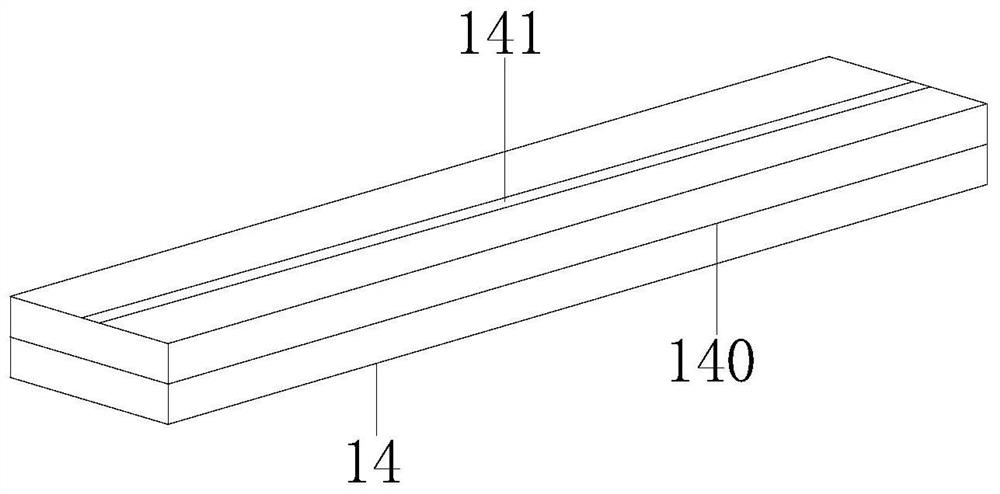

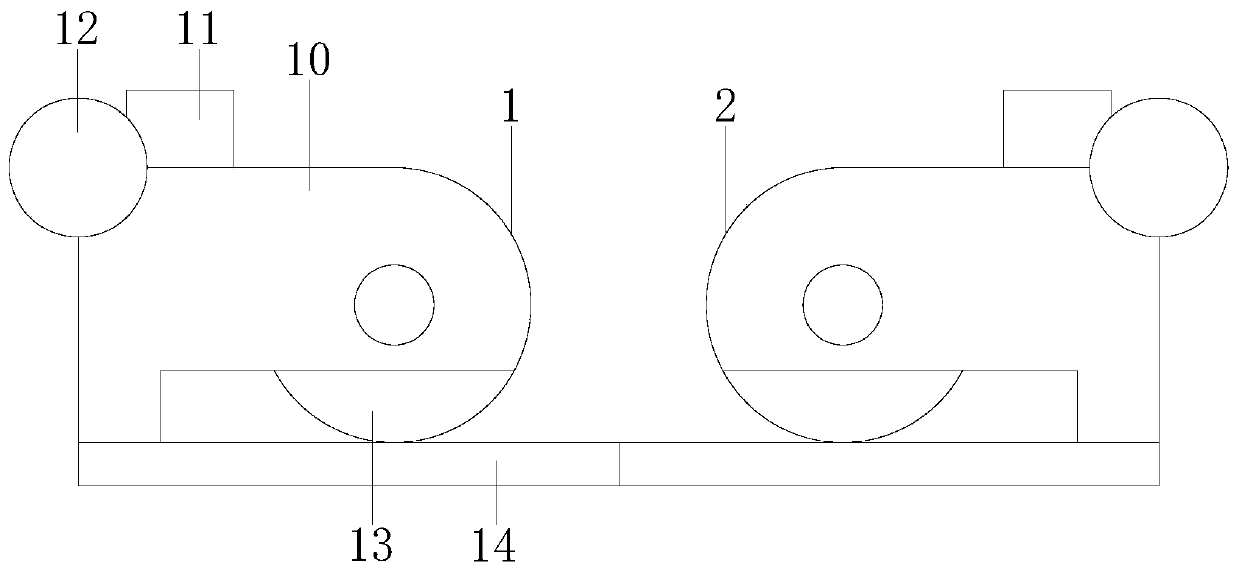

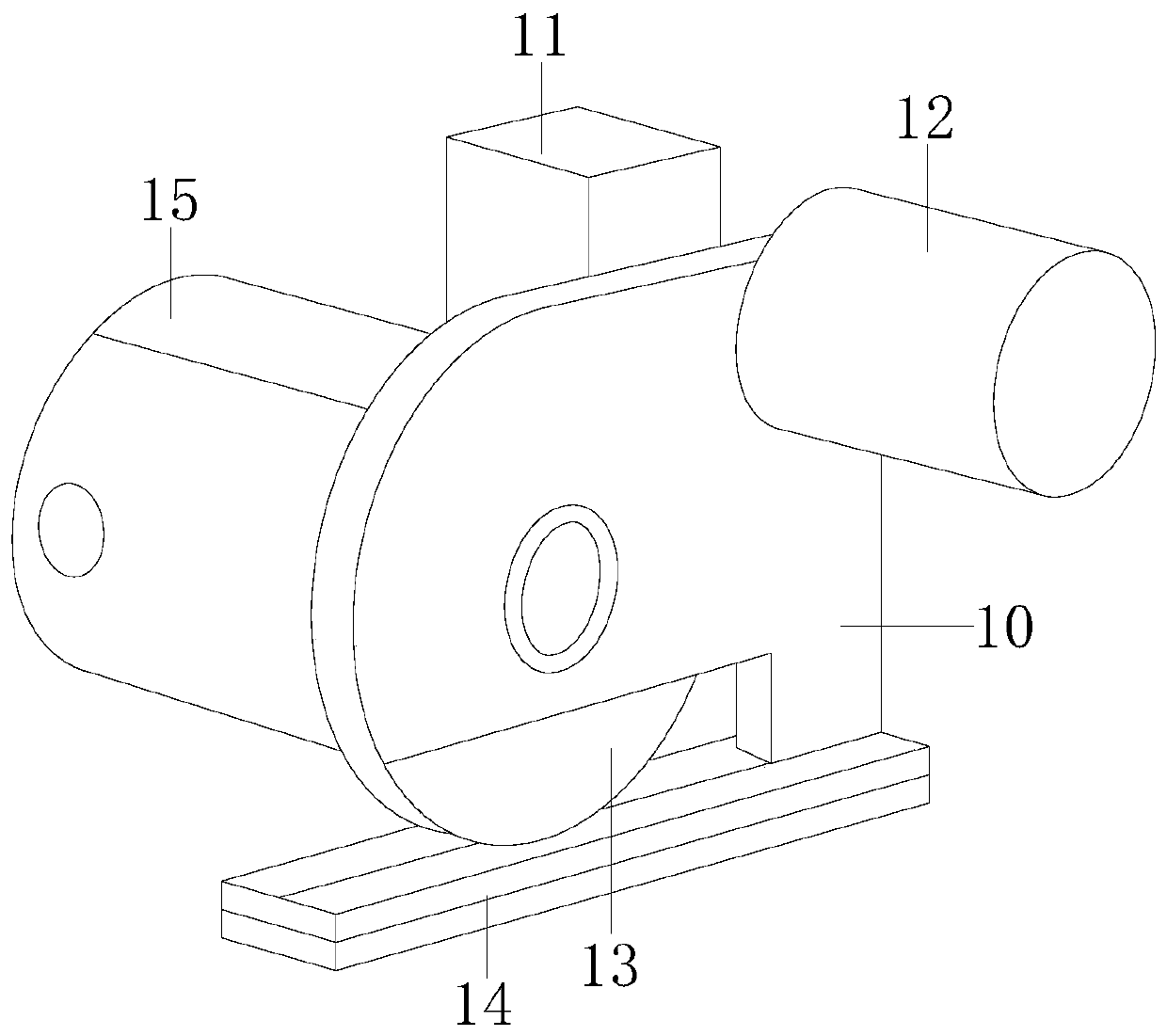

Accurate paper filler stuffing device for footwear making

InactiveCN106742403AImplement placement workPlay a role in strengtheningPackagingPulp and paper industryPaper sheet

The invention relates to a paper filler stuffing device, in particular to an accurate paper filler stuffing device for footwear making, and aims to solve the technical problem of providing the accurate paper filler stuffing device for the footwear making. In order to solve the technical problem, the invention provides the accurate paper filler stuffing device for the footwear making. The accurate paper filler stuffing device comprises a top plate, a first supporting rod, a swinging rod, a first spring, a placing device, a paper filler outlet device, a fixing rod, a movable stick, a connecting rod, a contact roller, a motor and the like, wherein a left bracket, a sliding rail, a second supporting rod, a bottom plate and a right bracket are sequentially arranged at the top of the bottom plate from left to right; the top plate is arranged at the top end of the left bracket; the first supporting rod and the paper filler outlet device are arranged at the bottom of the top plate; and the first supporting rod is located on the left side of the paper filler outlet device. According to the accurate paper filler stuffing device disclosed by the invention, the effect of being high in accuracy is achieved; and when the work of stuffing paper fillers is performed on shoes by the accurate paper filler stuffing device, the power of the motor is utilized to drive a stuffing rod to move towards the left, and the placing device is swung clockwise.

Owner:林永贵

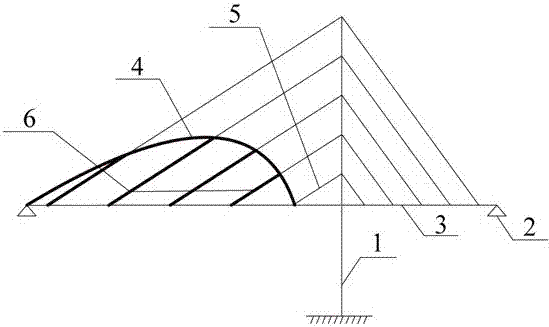

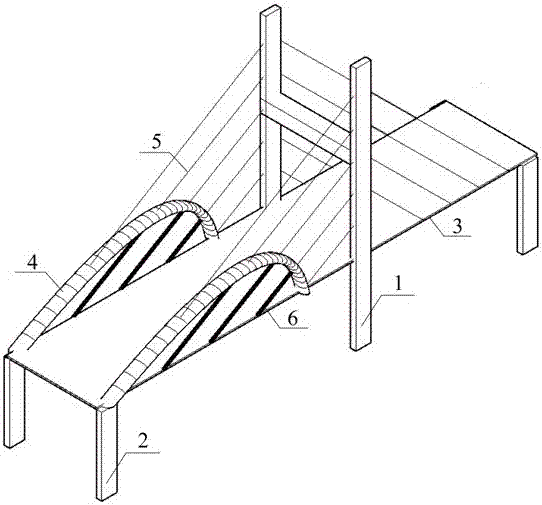

Butterfly-type cable-stayed bridge system

ActiveCN107100064AReduced deflectionReduce distortionCable-stayed bridgeBridge structural detailsCable stayedTower

The invention discloses a butterfly-type cable-stayed bridge system. The system comprises bridge towers, main girders, abutment piers, stayed cables and asymmetric curved arches. The asymmetric curved arches are arranged in a main span, and in the area, the two ends of each stayed cable are connected with the corresponding bridge tower and the corresponding asymmetric curved arch respectively. Inclined suspenders located on the same straight lines of the stayed cables are arranged at anchorage points on arch ribs, and the inclined suspenders are connected with the main girders. Meanwhile, the tension of the inclined suspenders is larger than the cable force of the stayed cables, so that the arch ribs are compressed, and at the moment, loads are born by the stayed cables and an arch-girder system together. The asymmetric curved arches have the stiffening effects on the stayed cables in the areas of the asymmetric curved arches, the main girders, the asymmetric curved arches and the inclined suspenders in the arches form a spatial framework structure together, and the space stiffness of the cable-stayed bridge main span is improved so as to be beneficial to the effect of resisting the wind loads; meanwhile, the downward deflection deformation of the main girders is reduced, the deformation of the stayed cables is reduced, so that the cable force of the main span is reduced, and the stress state of the bridge towers is improved.

Owner:TONGJI UNIV

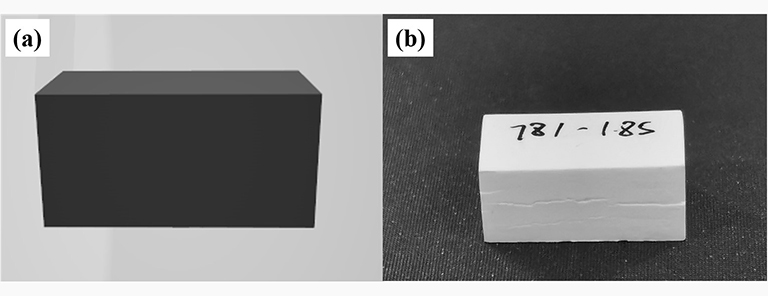

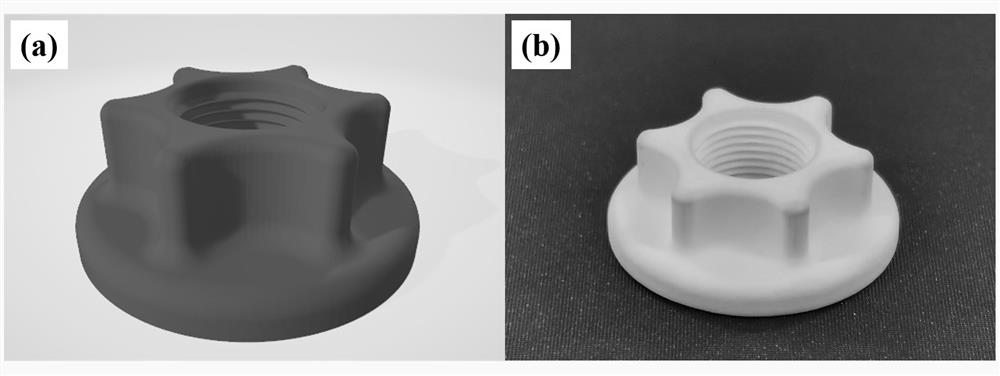

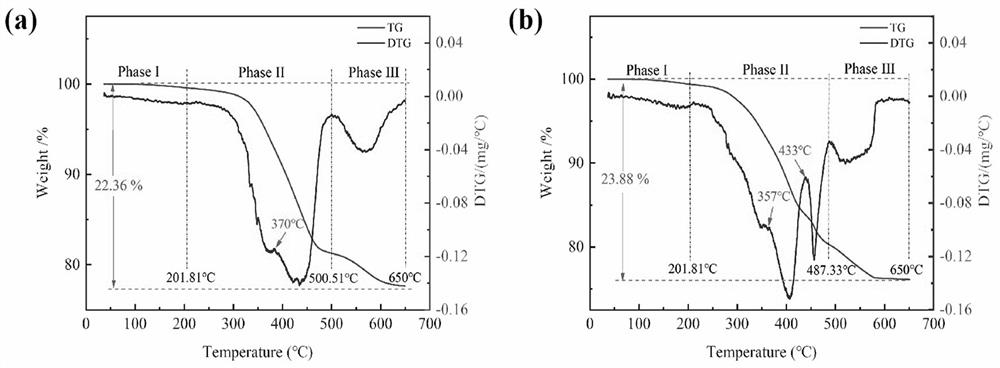

Ultra-thick crack-free aluminum oxide ceramic preparation method based on digital light treatment molding technolog

ActiveCN112573906AHigh precisionLow costAdditive manufacturing apparatusOxide ceramicComputer printing

The invention belongs to the technical field of 3D printing, and discloses an ultra-thick crack-free aluminum oxide ceramic preparation method based on a digital light treatment molding technology, which comprises the following steps: a) putting photosensitive resin, aluminum oxide powder, calcium carbonate powder and a dispersing agent into a ball mill, and stirring to obtain aluminum oxide ceramic slurry with solid phase content of 70-82%; b) drawing a three-dimensional graph by using Solids works, storing the three-dimensional graph as an STL format file, importing the three-dimensional graph into digital light processing forming printer matching software RayWareC for slicing, and exporting the sliced three-dimensional graph as an SSJ format file; c) pouring the alumina ceramic slurry into a trough, adjusting a printing platform, importing the SSJ format file model, setting printing parameters, and printing layer by layer to obtain a ceramic biscuit, wherein the printing parametersare set as follows: the curing time of the base layer is 15-20 seconds, the number of layers of the base layer is 5, and the curing time of the single layer is 1.5 seconds and 2.5 seconds; and d) sequentially putting the ceramic biscuit into a degreasing furnace and a sintering furnace for treatment to obtain the ultra-thick crack-free aluminum oxide ceramic.

Owner:ZHENGZHOU UNIV

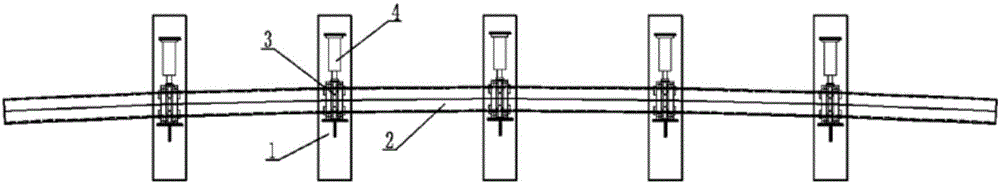

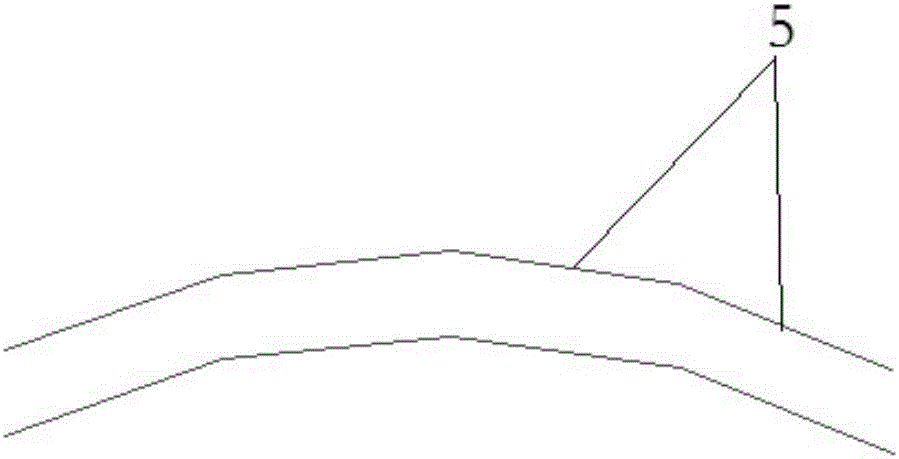

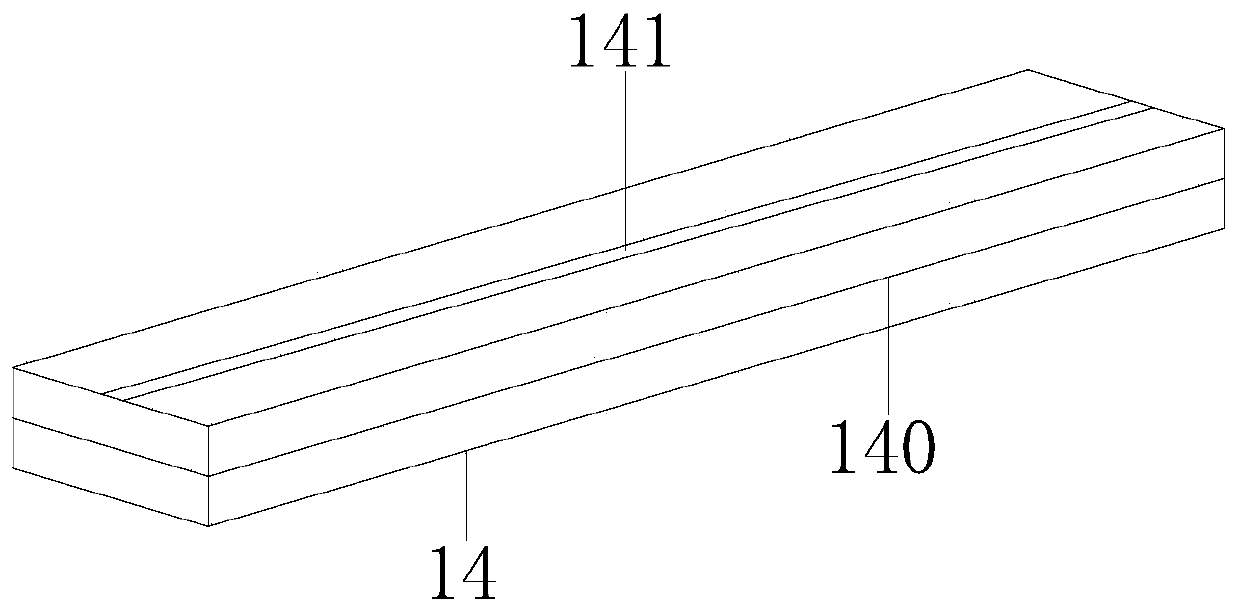

Steel box girder arc-shaped U rib installing and positioning method

ActiveCN106192765AGuaranteed Linearity RequirementsEasy to installBridge structural detailsBridge erection/assemblyStructural engineeringLine fitting

The invention provides a steel box girder arc-shaped U rib installing and positioning method. The method comprises the steps that a line drawing working platform is arranged in an area where a U rib of a steel box girder needs to be installed, and line drawing is conducted in a mode from the center to the two sides after leveling is conducted; stiffening plates are welded to the inner surface of the U rib at intervals; the U rib is installed from one end of a well-drawn approximate curve to the other end of the approximate curve; when installation is conducted, support plates and wedge blocks are used for fixing the U rib, a steel hammer is used for hammering, the U rib is bent towards one side, after the U rib is overlapped with a current straight-line segment, point welding is conducted to fix the overlapped portions of the U rib and the straight-line segment, and installation is continuously conducted to enable the U rib to be overlapped with a next straight-line segment till the U rib is completely overlapped with the approximate curve; the support plates and the wedge blocks are removed; the steel box girder which is well provided with the U rib is placed on an in-plant anti-deformation jig frame for whole welding. According to the steel box girder arc-shaped U rib installing and positioning method, the straight-line fitting circular-arc curve serves as the basic principle, full cross-section heating does not need to be conducted on the whole U rib at certain intervals, and installation of the arc-shaped U rib can be completed conveniently and rapidly.

Owner:CHINA FIRST METALLURGICAL GROUP

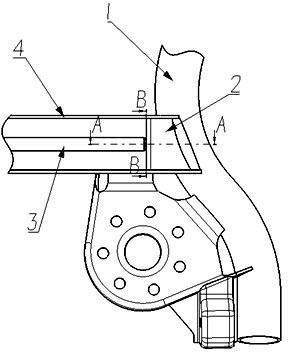

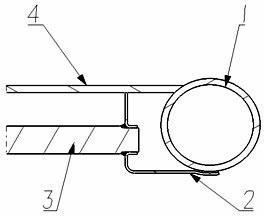

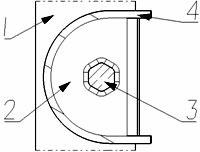

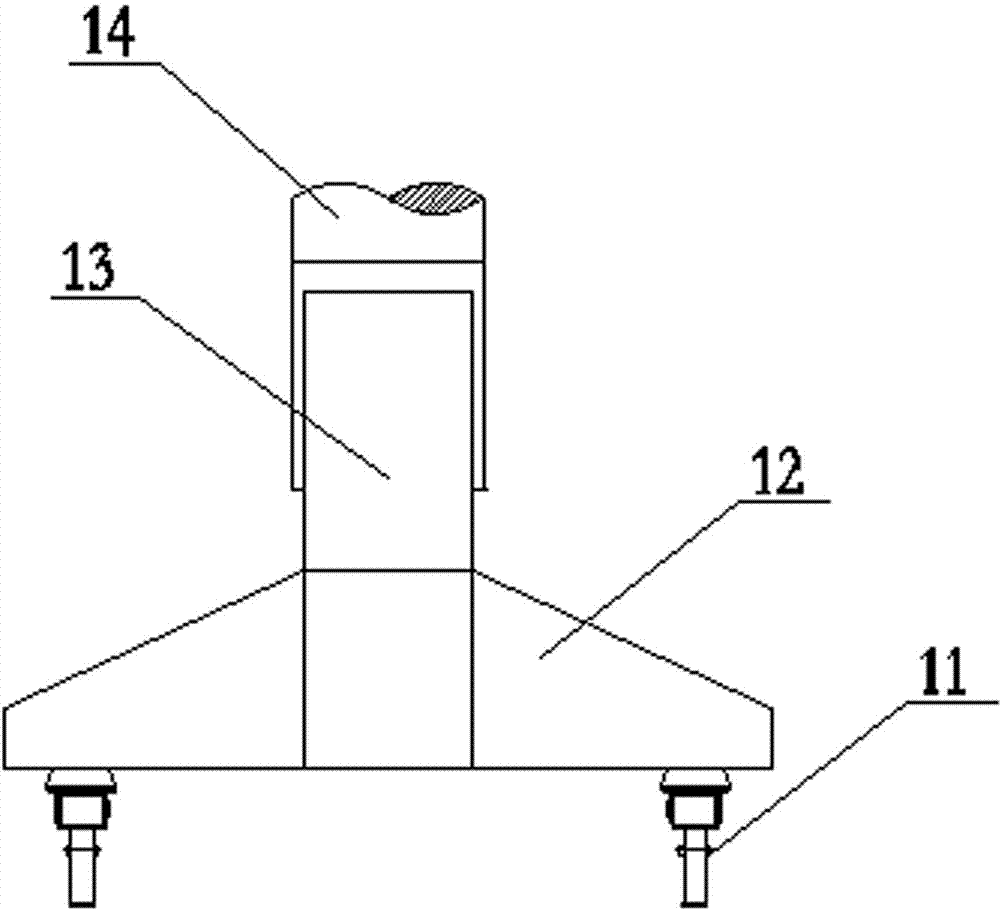

Installing and fixing structure of suspension torsion bar of torsion beam of automobile

InactiveCN102381151APlay a role in strengtheningImprove connection strengthResilient suspensionsInterference fitEngineering

The invention discloses an installing and fixing structure of a suspension torsion bar of a torsion beam of an automobile, comprising a middle bracket and the torsion bar. The installing and fixing structure is characterized in that the section of the middle bracket is L-shaped; the upper end of the vertical part of the middle bracket is fixedly connected with a torsion cross beam; the upper surface of the right end of the horizontal part of the middle bracket is fixedly connected with one side of a longitudinal arm; the right end of the torsion cross beam is fixedly connected with the other side of the longitudinal arm; the middle part of the vertical part of the middle bracket is provided with a polygonal flanging hole; the right end part of the torsion bar is of a polygonal structure correspondingly; and the polygonal structure is in interference fit with the polygonal flanging hole on the middle part of the vertical part of the middle bracket, and the polygonal structure and the polygonal flanging hole are fixedly connected by welding. In the installing and fixing structure, the connecting strength between the torsion bar and the longitudinal arm is improved, the strength requirement for welding seams is reduced, so that the whole connecting strength is well improved and the service life of the whole part is prolonged; and the problems of low strength and cracking of the welding seams for adopting direct welding between the torsion bar and the longitudinal arm generally are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

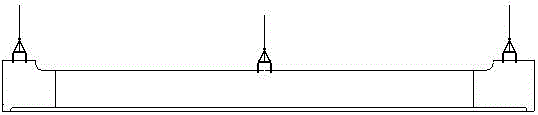

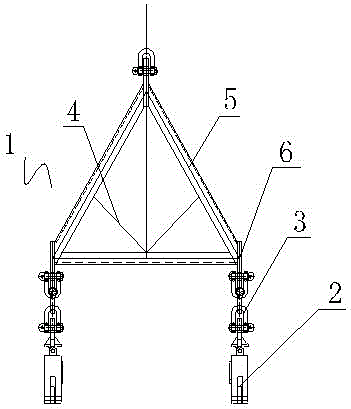

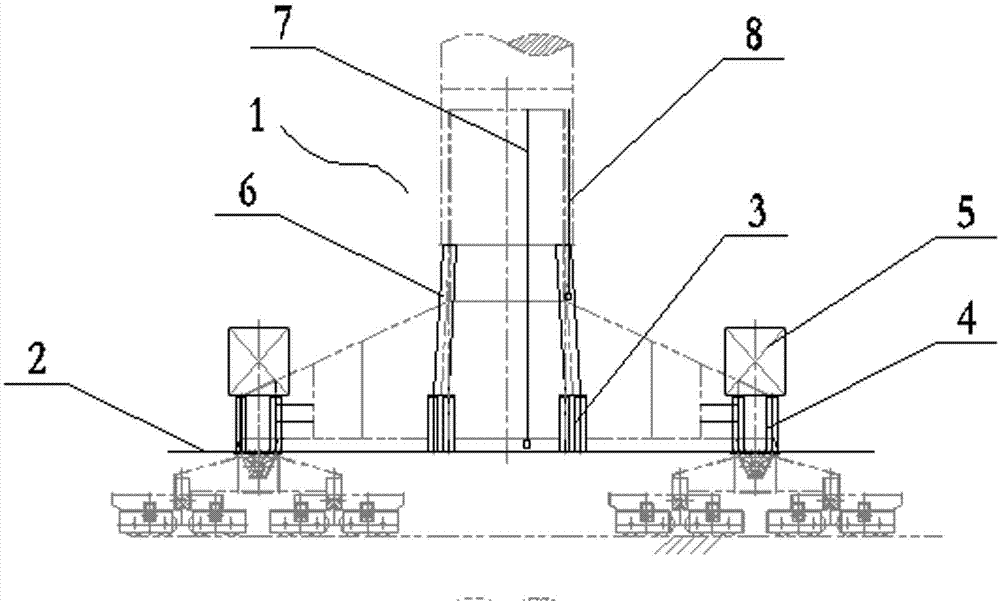

Technology for hoisting web of girder by using rail-mounted gantry crane

ActiveCN105883580AReduce manufacturing costSimple structureLoad-engaging elementsSteel platesGantry crane

The invention relates to a technology for hoisting a web of a girder by using a rail-mounted gantry crane. The technology comprises the following specific steps: determination of the position of a hoisting point: selecting a suitable position of the hoisting point on the web of the girder, and welding a mounting stopper at the position of the hoisting point; preparation before hoisting: connecting the upper end of each triangular hanger to a hoisting steel wire rope by a shackle, connecting the left side and the right side of the lower end of each triangular hanger by using three shackles and then connecting the lower end of each triangular hanger to vertical lifting steel plate hoisting tongs; hoisting: slowly hoisting, staying for 10 minutes when distant from a jig frame by 200 mm, observing whether steel plates surrounding the vertical lifting steel plate hoisting tongs are abnormal or not, whether various force bearing points are abnormal or not and whether stress on the steel wire rope is uniform or not, and hoisting to a required height or overturning if abnormity does not exist; and hanger disassembling: after the whole web of the girder is welded with a box fixedly and firmly, disassembling the hangers. The technology for hoisting the web of the girder by using the rail-mounted gantry crane has the advantages that any consumption in aspects of discharging of parts, welding materials, gas consumption, flaw detection and the like is not required, and the production cost is greatly saved.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

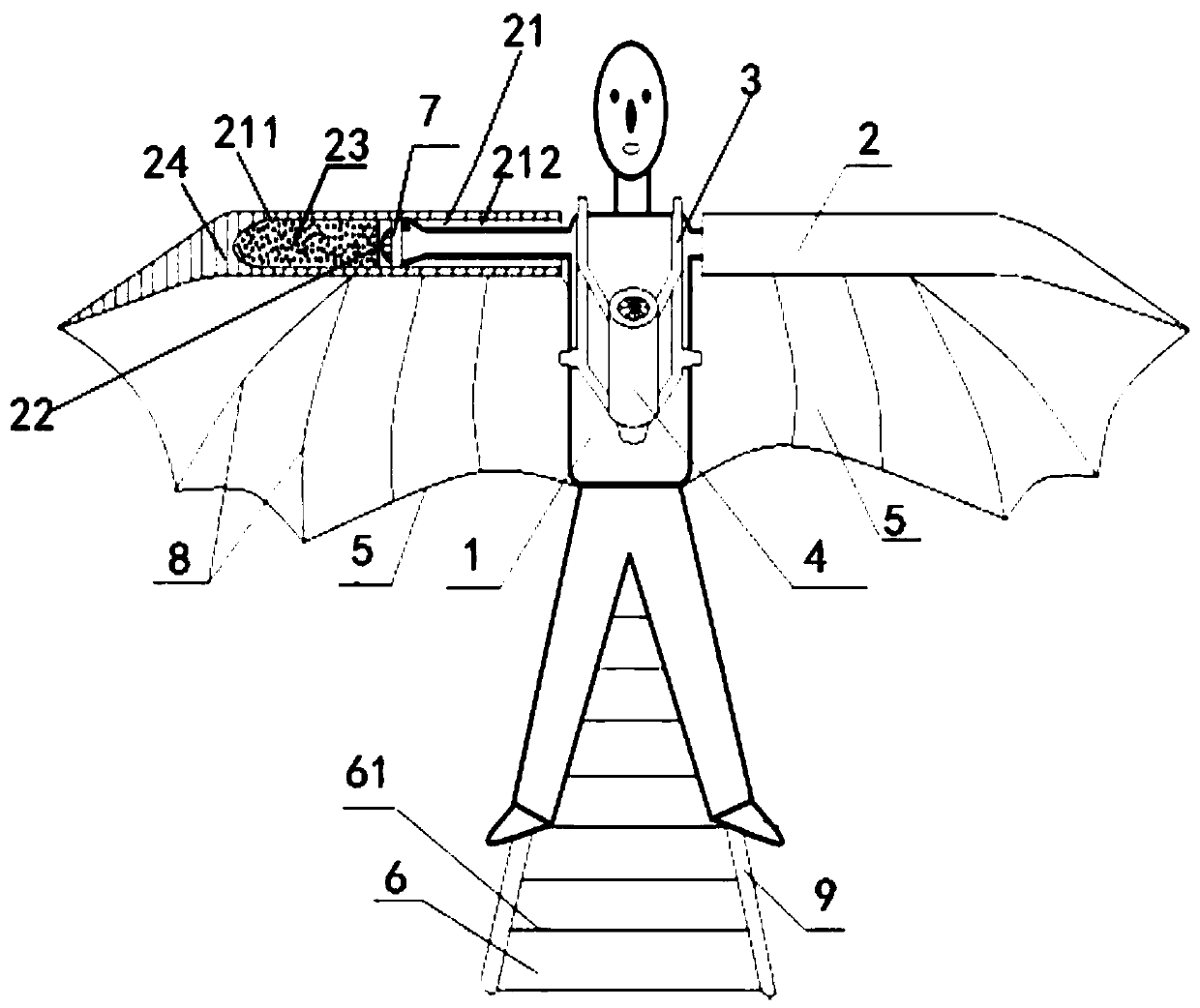

Power wingsuit

The embodiment of the invention discloses a power wingsuit. The power windsuit includes a flight suit, two extension tubes horizontally arranged on the outer sides of two shoulders of flight staff, aholding frame, one or more power flight devices, two flight wing membranes, an empennage wing membrane and a control switch, wherein one ends of the extension tubes are opened, and the other ends of the extension tubes are closed; the holding frame sleeves the flight suit; the power flight devices are mounted on the holding frame, and the power ejecting ends face towards the foot position of the flight staff; the two flight wing membranes correspond to the two expansion tubes, the side edges of the flight wing membranes in the longitudinal directions of the outer walls of the expansion tubes are connected to the lower surfaces of the outer walls of the expansion tubes, and the ends, close to the flight staff, of the flight wing membranes are connected with the outer surfaces, correspondingto the armpit and the rib of the flight staff, of the flight suit; the empennage wing membrane is connected to the outer surface, between two legs of the flight staff, of the flight suit; and the control switch is mounted on the end, close to the hands of the flight staff, of the inner side of a chamber of one of the expansion tubes. Compared with a traditional wingsuit, the power wingsuit has the advantages that the flight speed is high, the auto-hover time is long, the safety is high, the comprehensive using cost is low, operation is easy and quick, and long-term complex training is not needed.

Owner:李明珠

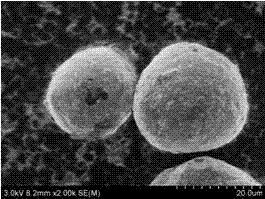

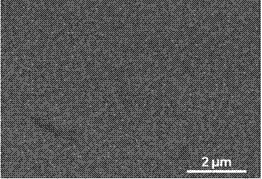

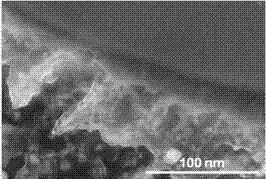

A kind of aluminum-based nanocomposite material based on slm forming and its preparation method

ActiveCN105803271BPlay a role in strengtheningReduce the chance of stress concentrationAdditive manufacturing apparatusIncreasing energy efficiencyMicrometerRare earth

The invention belongs to the field of aluminum-based nanocomposite materials, and specifically relates to an aluminum-based nanocomposite material formed based on SLM and a preparation method thereof. The aluminum-based nanocomposite material is obtained by forming aluminum-based nanocomposite powder through SLM; The aluminum-based nanocomposite powder includes a ceramic phase, a rare earth phase and an aluminum matrix phase; the SLM forming process parameters are: the laser power is between 100W, 120W and 130W or 100-130W, the scanning distance is 30 µm and the powder layer thickness is 50 µm; the effective bulk energy density is controlled at 288‑398.65 J / mm3. Effectively solve the problems of mismatching process performance and mechanical properties, uneven distribution of reinforcement particles and poor wettability between ceramic phase and substrate phase in the laser additive process of aluminum-based nanocomposites, so that the obtained products have Good interfacial bonding and excellent mechanical properties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

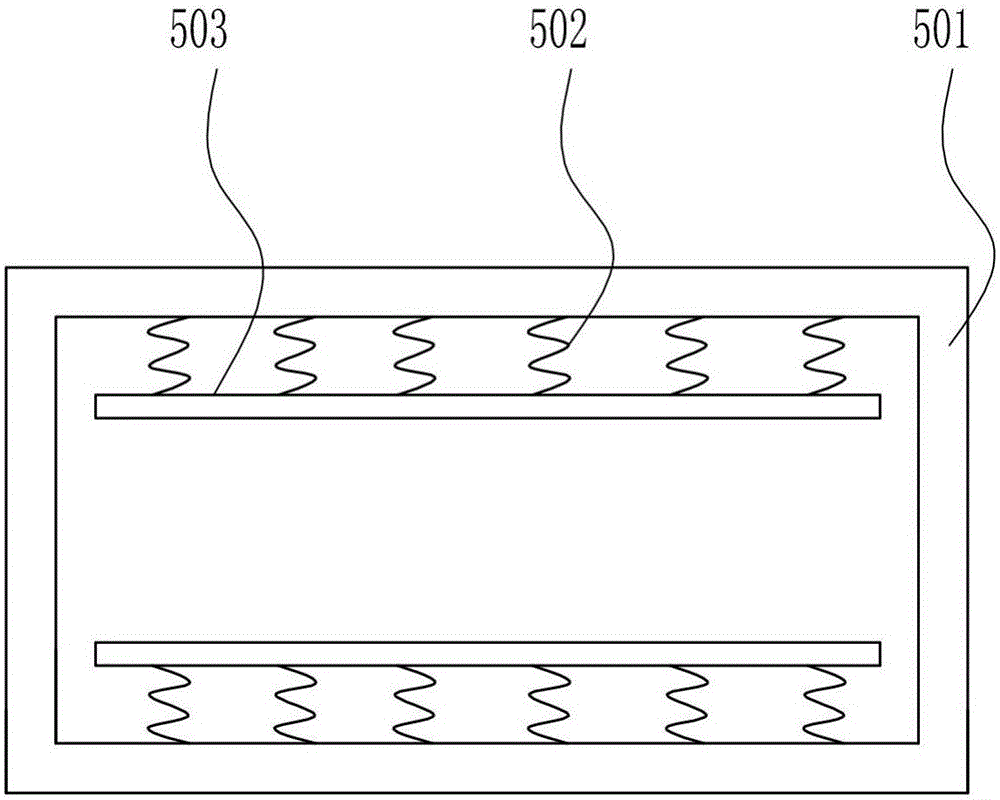

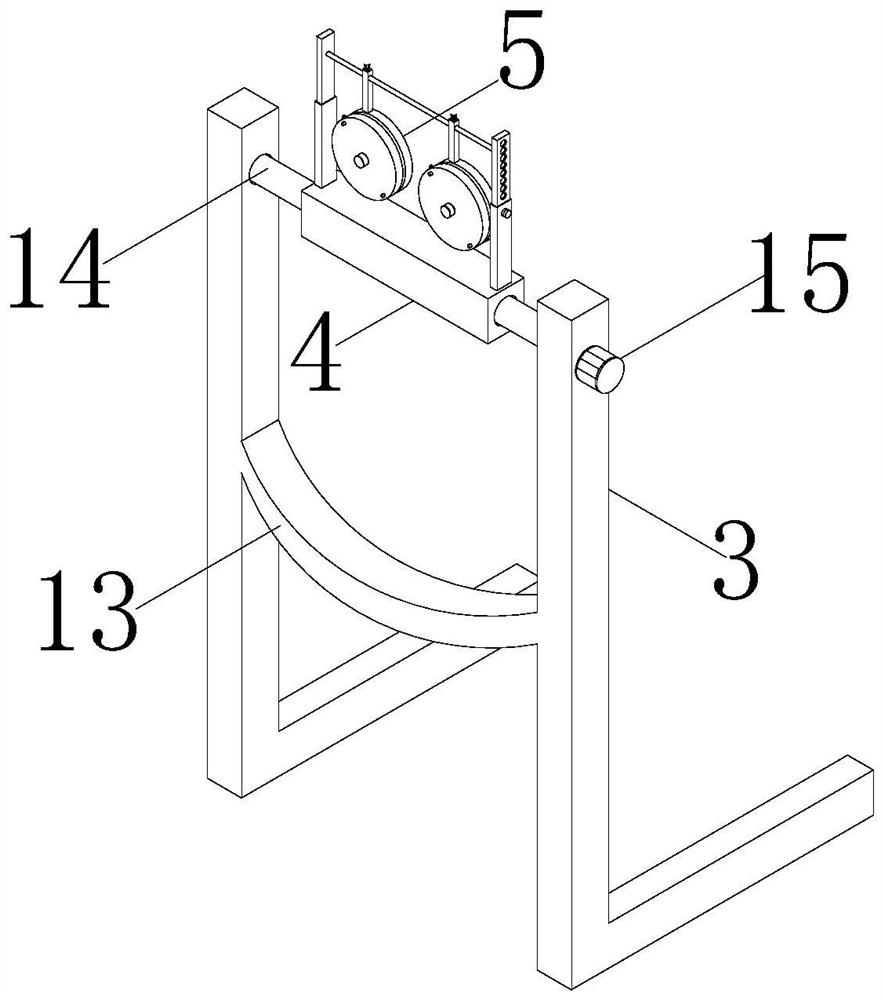

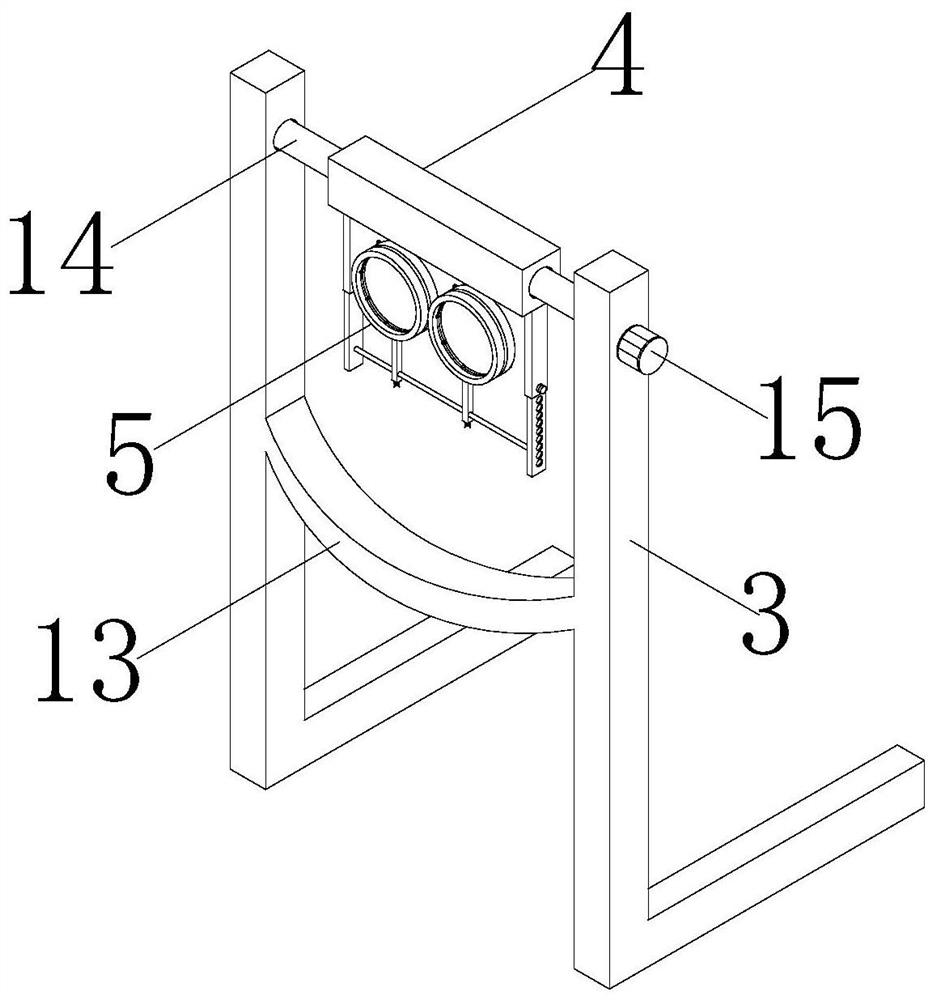

Light feeding instrument for vision correction

PendingCN114225227AGood treatment effectPromote circulationRoller massageLight therapyMedicineMassage

The light feeding instrument for vision correction comprises a light feeding instrument body and an observation opening formed in the light feeding instrument body, a bracket located on one side of the observation opening is installed on the light feeding instrument body, and an assembly block and a first driving piece used for driving the assembly block to rotate are installed on the bracket; two massage lens cones are arranged on the assembly block, the distance between the two massage lens cones is adjustable, notches are formed in the massage lens cones, annular grooves are formed in the notches, and elastic massage pieces and second driving pieces used for driving the elastic massage pieces to slide in the annular grooves are arranged in the annular grooves. According to the light feeding instrument for vision correction, after the light feeding instrument is used, the eyes of people can be massaged conveniently, so that circulation of eye blood is promoted, and the treatment effect is improved.

Owner:安徽中仪医疗科技有限公司

Rice husk modified silane-crosslinked polyethylene insulation composite material and preparation method thereof

The invention discloses a rick husk modified silane-crosslinked polyethylene insulation composite material, which is characterized by being prepared from the following raw materials in parts by weight: 120 to 150 parts of low-density polyethylene resin, 20 to 30 parts of rick husk, 5 to 10 parts of diatomite, 2 to 4 parts of sodium silicate, 2 to 4 parts of linear phenolic resin, 2 to 3 parts of polypropylene glycol, 0.3 to 0.5 part of diphenyl-methane-diisocyanate, 1 to 2 parts of cotton seed oil, 1 to 2 parts of hydroxy silicone oil, 0.5 to 1 part of chlorinated paraffin, and 3 to 6 parts of silane complexing agent. The provided silane-crosslinked polyethylene insulation composite material has the advantages of high strength and toughness, good weatherability, excellent water resistant and corrosion resistant performance, energy saving property, and environment-friendliness, and can generate social benefit and economic benefit.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

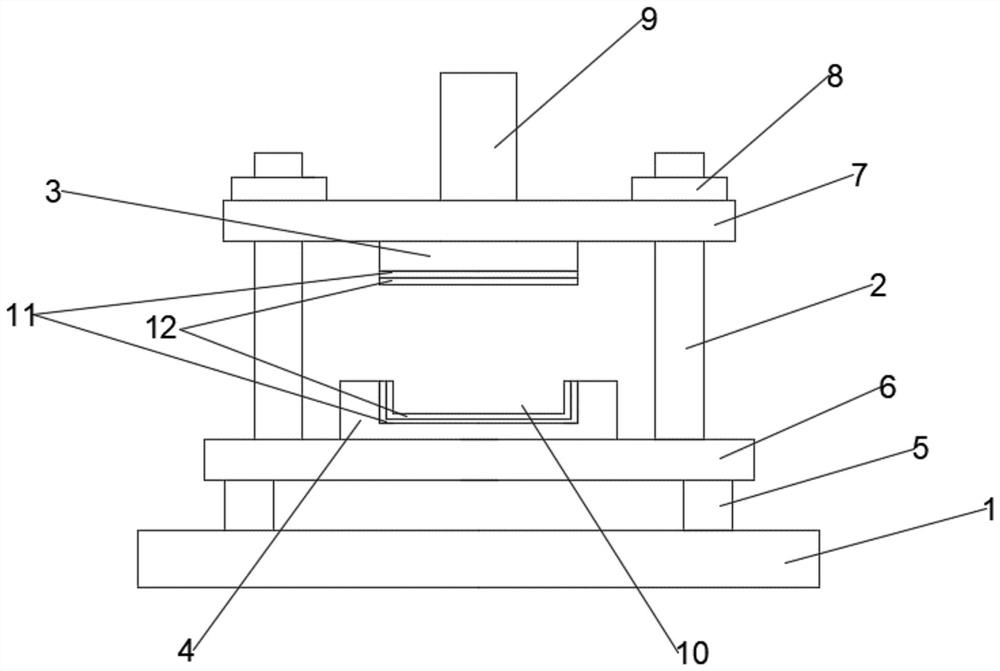

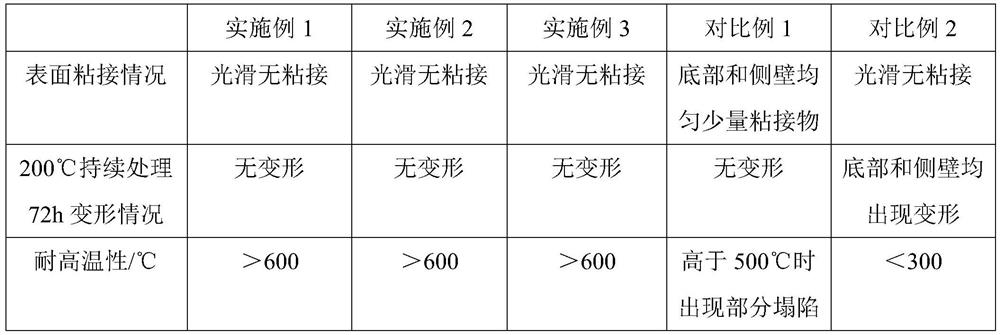

Machining equipment for injection mold casting

The invention relates to machining equipment for injection mold casting. The equipment comprises a fixed bottom plate, guide columns, an upper mold and a lower mold, a plurality of fixed columns are fixedly arranged on the upper surface of the fixed bottom plate, and a supporting plate is arranged at the upper ends of the fixed columns; the lower mold is correspondingly arranged below the upper mold, the lower mold is fixedly arranged above the supporting plate, and a cavity of a concave structure is formed in the upper surface of the lower mold; and the lower surface of the upper mold and the surface of the cavity are each provided with an easy-to-demold layer, and each easy-to-demold layer comprises a reinforcing layer and an anti-adhesion layer which are sequentially arranged from inside to outside. According to the machining equipment for injection mold casting, the machining equipment for injection mold casting is arranged to be of an integrated structure of the fixed bottom plate, the guide columns, the upper mold and the lower mold, the fixed bottom plate and the guide columns play a supporting and fixing role, so that normal operation of the upper mold and the lower mold is guaranteed, the overall structure is firmer through the connection relation of the guide columns, the supporting plate and a connecting plate, the connecting strength is high, and collapse and falling are not prone to occurring in the using process.

Owner:广州盈在科技有限公司

A method for strengthening wood in solid wood with small molecule phenolic monomer

ActiveCN103600389BHigh viscosityLarge infusion resistancePressure impregnationPolymerisation impregnationSolid woodPolymer science

A method for strengthening wood with small molecular phenolic monomers in solid wood. It is a method of in-situ polymerization of small molecular phenolic monomers in solid wood to form phenolic resins to strengthen wood. First, uniformly mixed phenolic monomers are mixed by vacuum high pressure technology. The body, formaldehyde monomer and catalyst are immersed in the interior of the wood; then, after aging and homogeneity, the polymerization reaction is initiated by heating or microwave, so that the phenol monomer and formaldehyde monomer are polymerized in situ in the wood channel to form a phenolic resin. The phenolic resin filling the wood channels plays a compact and strengthening effect on the wood, which can improve the compressive strength, wear resistance, water resistance, dimensional stability and processability of the wood, increase the texture of the wood, and reduce the cracking and deformation of the wood.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

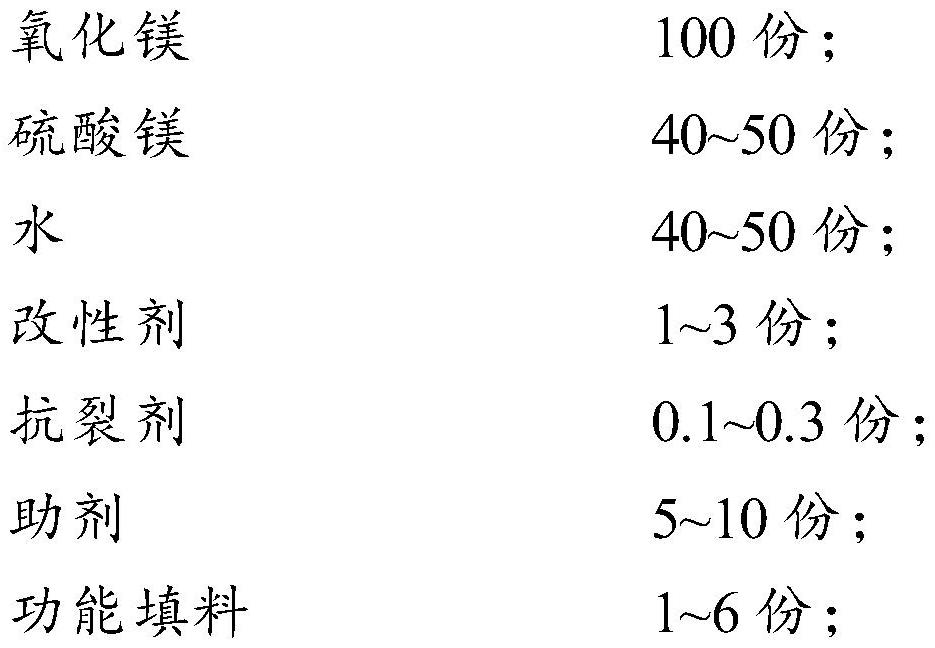

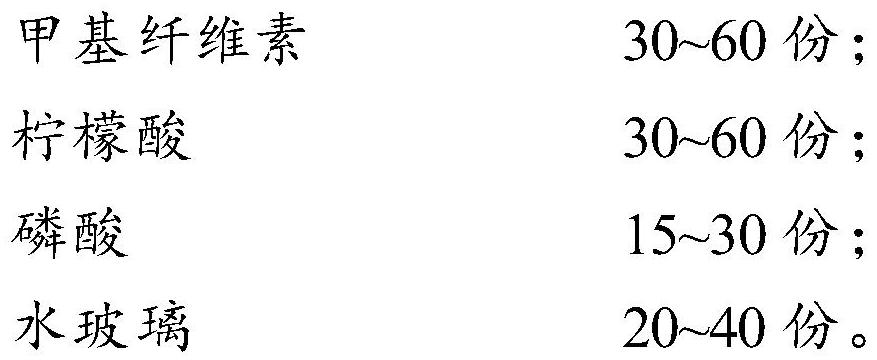

Composite anti-corrosive coating and preparation method thereof

InactiveCN113429812AResistant to crackingAchieve anti-corrosion effectAnti-corrosive paintsCelluloseO-Phosphoric Acid

The invention provides a composite anti-corrosive coating and a preparation method thereof. The composite anti-corrosive coating provided by the invention is prepared from the following raw materials in parts by weight: 100 parts of magnesium oxide; 40-50 parts of magnesium sulfate; 40-50 parts of water; 1-3 parts of a modifier; 0.1-0.3 parts of an anti-cracking agent; 5-10 parts of an auxiliary agent; and 1-6 parts of a functional filler. The modifier comprises methyl cellulose, citric acid, phosphoric acid and water glass. The functional filler comprises graphene. The ultraviolet aging resistance, heat insulation property and adhesive strength of the composite anti-corrosive coating provided by the invention can be improved while the corrosion resistance is ensured.

Owner:HAINAN UNIVERSITY

Mildewproof and waterproof organosilane crosslinked polyethylene insulated composite material and preparation method thereof

InactiveCN104987568AImprove weather resistanceImprove toughnessPigment treatment with macromolecular organic compoundsWaxCross-linked polyethylene

The invention discloses a mildewproof and waterproof organosilane crosslinked polyethylene insulated composite material. The mildewproof and waterproof organosilane crosslinked polyethylene insulated composite material is characterized by being prepared from, by weight, 120-150 parts of low-density polyethylene resin, 2-4 parts of phenolic novolac resin, 10-15 parts of vermiculite powder, 10-15 parts of talcum powder, 1-2 parts of styrene-acrylic emulsion, 2-3 parts of polypropylene glycol, 0.3-0.5 part of methylene diphenyl diisocyanate, 1-2 parts of glycerol monolaurate, 0.3-0.5 part of zinc naphthenate, 0.2-0.4 part of propylparaben, 2-4 parts of linseed oil, 3-5 parts of polyethylene wax and 3-6 parts of silane complexing agent. The organosilane crosslinked polyethylene insulated composite material is good in strength, toughness, weather resistance, corrosion resistance, waterproof performance and mildewproof performance, capable of effectively restraining reproduction and growth of mould, suitable for being used in a humid environment and beneficial for keeping sanitation and hygiene of the environment and prolonging the service life of a product.

Owner:合肥蓝科新材料有限公司

Corrosion-resistant silane crosslinked polyethylene insulation composite material and preparation method thereof

The invention discloses a corrosion-resistant silane crosslinked polyethylene insulation composite material. The corrosion-resistant silane crosslinked polyethylene insulation composite material is prepared from 120-150 parts by weight of low density polyethylene resin, 3-5 parts by weight of phenolic novolac resin, 5-10 parts by weight of glass fibers, 10-15 parts by weight of barite powder, 1-2 parts by weight of titanium dioxide, 2-3 parts by weight of polypropylene glycol, 0.3-0.5 parts by weight of diphenyl-methane-diisocyanate, 1-2 parts by weight of hydrogenated castor oil, 1-2 parts by weight of N,N'-ethylenebis(stearamide) and 3-6 parts by weight of a silane complexing agent. The corrosion-resistant silane crosslinked polyethylene insulation composite material has the advantages of good strength, good toughness, weatherability, water resistance, excellent corrosion resistance, high safety and wide application range.

Owner:合肥蓝科新材料有限公司

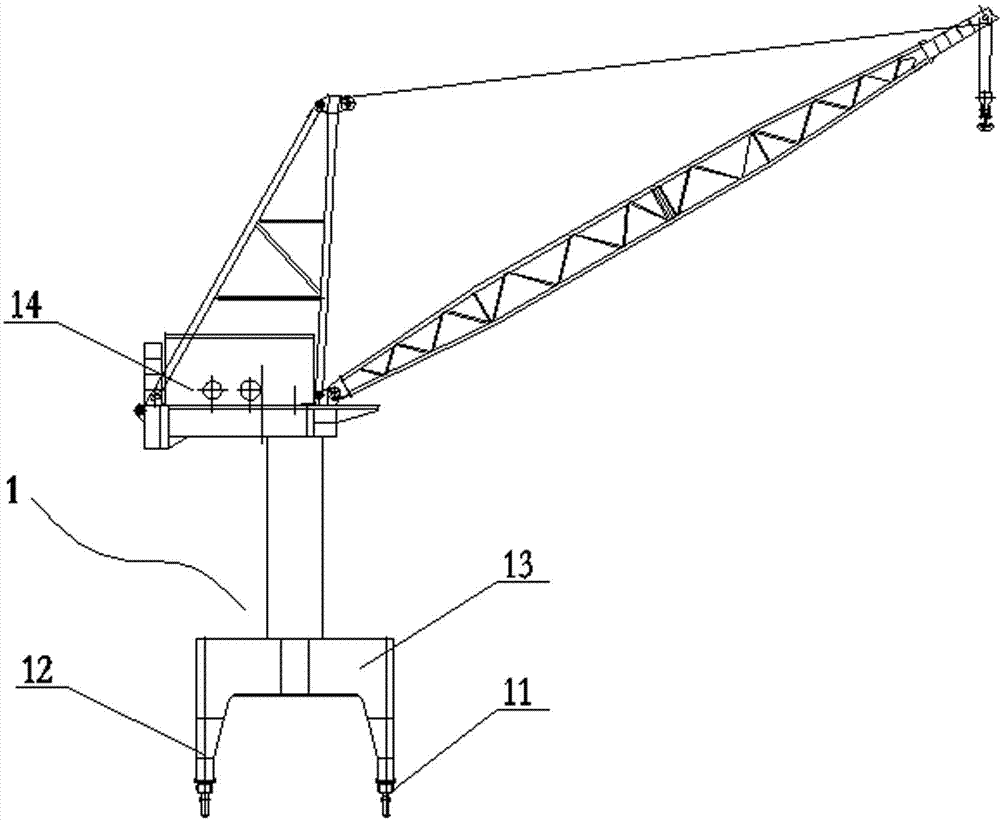

Quick movement tooling for gantry crane

The invention relates to a quick movement tooling for a gantry crane. The quick movement tooling for the gantry crane comprises a lifting and transportation flat car, two middle transverse beams, two end transverse beams, two movement supports and counterweights, wherein the two middle transverse beams are arranged in parallel in a spaced manner between the two end transverse beams, the four transverse beams are supported on the lifting and transportation flat car, the two movement supports are respectively arranged on the two middle transverse beams or the lifting and transportation flat car, and the counterweights are respectively arranged on the two end transverse beams. By using the flat car to lift the gantry crane to move the gantry crane on the whole, the expenses in disassembling and lifting are reduced, the connecting pieces and structure of the gantry crane are not disassembled and damaged, the original performance of the original machine is kept, and the secondary damage caused during disassembling and the quality problem of installation uncertainty are reduced. The tooling has the advantages of easiness in use, operation and control and high safety factor.

Owner:JIANGSU YANGZI XINFU SHIPBUILDING CO LTD

Intelligent water supply device for ecological agriculture

InactiveCN110670669ASave resourcesPlay a protective effectGeneral water supply conservationWatering devicesEcologyProgrammable logic controller

The invention discloses an intelligent water supply device for ecological agriculture. The intelligent water supply device comprises a water tank, an illuminance sensor, a PLC (programmable logic controller), a first water pump, an electromagnetic valve, a soil layer and flow guide cylinders, wherein a water inlet is formed in the upper part of the exterior of the water tank, a temperature sensoris arranged on the left side of the exterior of the water tank, the PLC (programmable logic controller) is arranged on the left side of the exterior of the water tank, a water outlet pipe is arrangedon the upper right side of the exterior of the water tank, the first water pump is arranged under the end part of the water outlet pipe, the electromagnetic valve is arranged on the water outlet pipe,inclined plates are arranged on the right sides of the exteriors of enclosing walls, the flow guide cylinders are arranged at the upper part of the interior of the soil layer, and connecting pipes are arranged under the end parts of the flow guide cylinders and communicate with the water tank through a water inlet pipe. According to the intelligent water supply device, the water tank, the illuminance sensor, the temperature sensor, the PLC (programmable logic controller), slopes, the flow guide cylinders and the water inlet pipe are arranged, so that the problems that intelligent water supplycannot be realized, rainwater cannot be collected when it rains, and then resources are wasted can be solved.

Owner:安徽鑫科禾科技有限公司

Organosilane crosslinked polyethylene insulating composite material for mine and preparation method thereof

InactiveCN104844903AImprove toughnessEvenly dispersedPlastic/resin/waxes insulatorsLow-density polyethyleneMoisture resistance

The invention discloses an organosilane crosslinked polyethylene insulating composite material. The material is characterized by being prepared from the following raw materials in parts by weight: 120-150 parts of low-density polyethylene resin, 3-5 parts of bisphenol A epoxy resin, 2-4 parts of phenolic novolac resin, 10-15 parts of waste glass powder, 10-15 parts of coal gangue powder, 2-3 parts of polypropylene glycol, 0.3-0.5 part of diphenyl methane diisocyanate, 2-4 parts of polyglycerol polyricinoleate, 1-2 parts of barium petroleum sulfonate and 3-6 parts of silane compound. The organosilane crosslinked polyethylene insulating composite material has the advantages of good strength and toughness, good weather resistance, water resistance and corrosion resistance performance, superior wear resistance, moisture resistance and high temperature resistance performance, high use safety and suitability for mine electric wires and cables.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

High-strength anti-scraping silane crosslinked polyethylene insulation composite and preparation method thereof

The invention discloses a high-strength anti-scraping silane crosslinked polyethylene insulation composite. The composite is characterized by being produced through raw materials of, by weight part, 120 to 150 of low-density polyethylene resin, 2 to 4 of linear phenol-formaldehyde resin, 3 to 5 of boron nitride, 1 to 2 of nanometer aluminum alloy, 10 to 15 of talcum powder, 5 to 10 basalt powder, 2 to 3 of polypropylene glycol, 0.3 to 0.5 of diphenyl-methane-diisocyanate, 0.3 to 0.5 of triglycidyl isocyanurate, 2 to 4 of magnesium stearate, 3 to 5 of palm oil and 3 to 6 of silane complexing agents. The composite has the advantages of being good in strength and toughness, good in weather resistance and anti-corrosion performance, high good in anti-scraping and anti-scratching performances, good in use performance and wide in application range.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

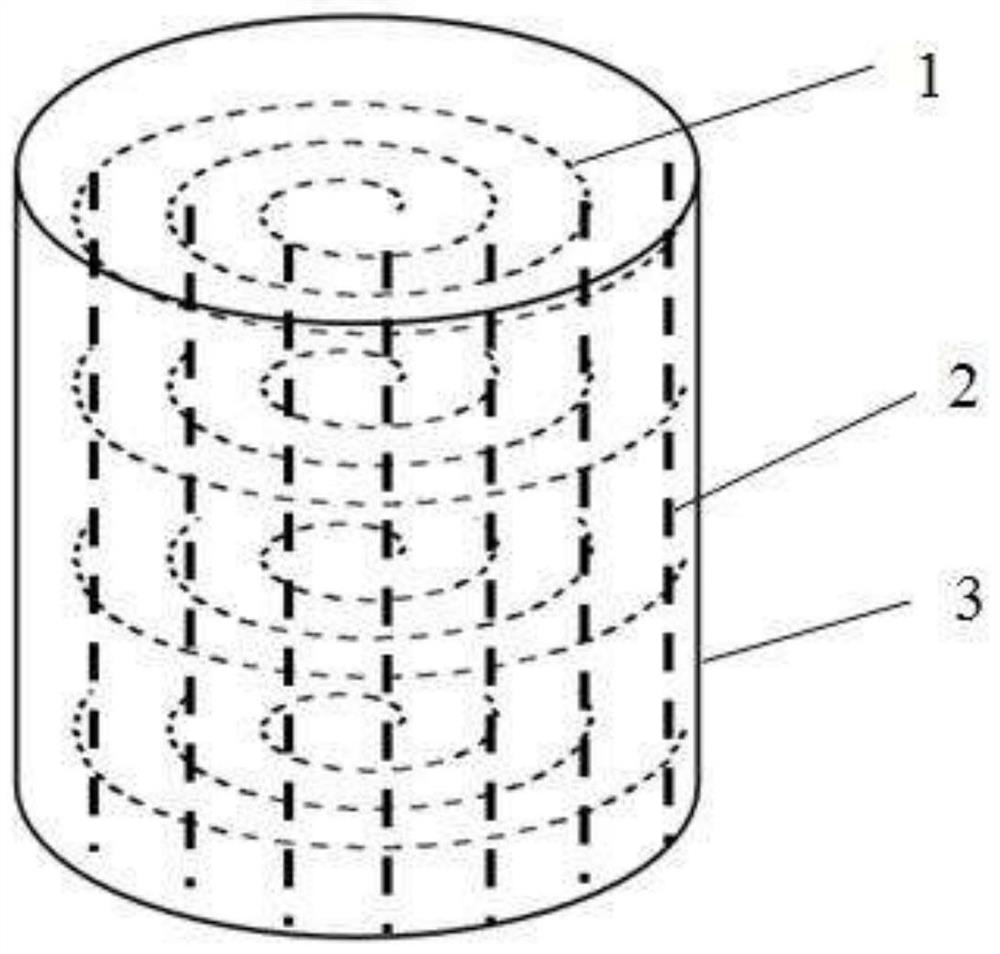

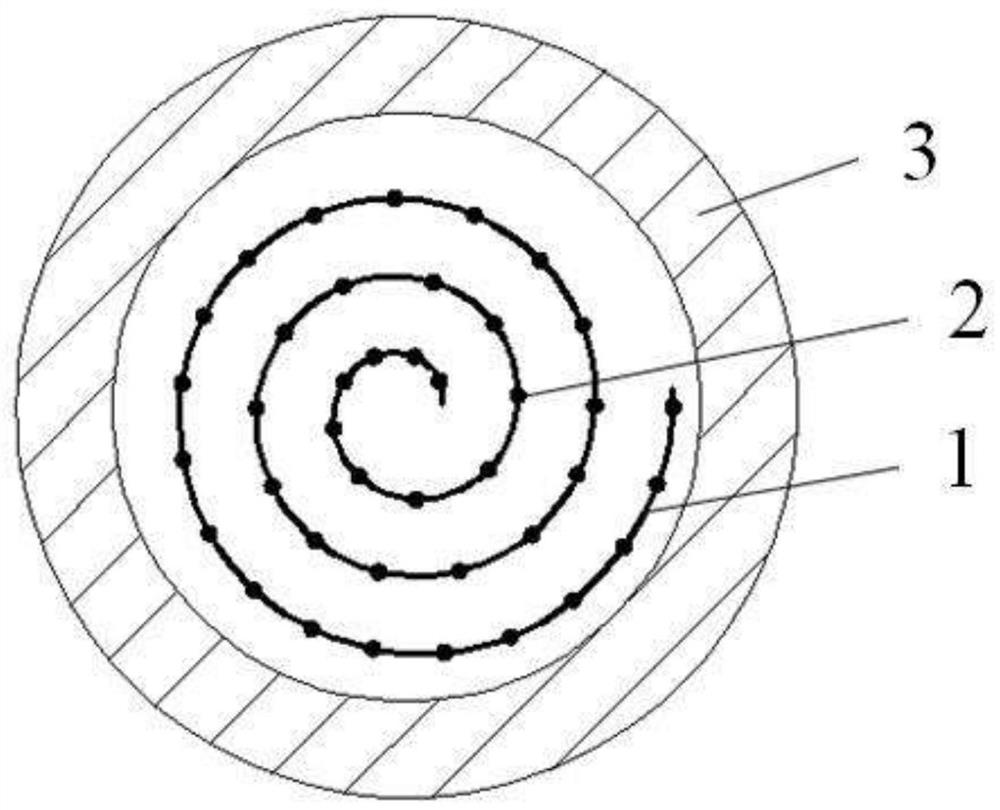

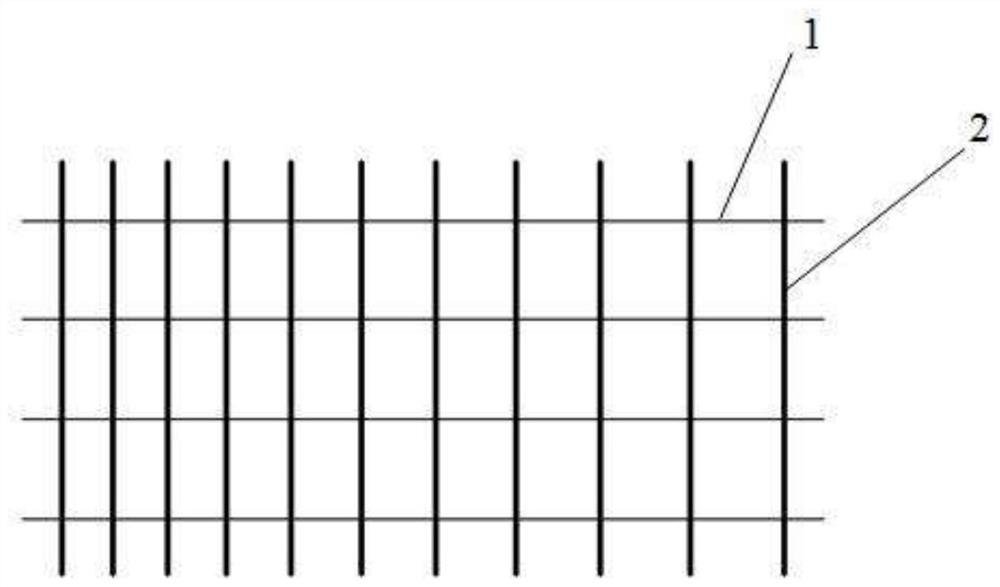

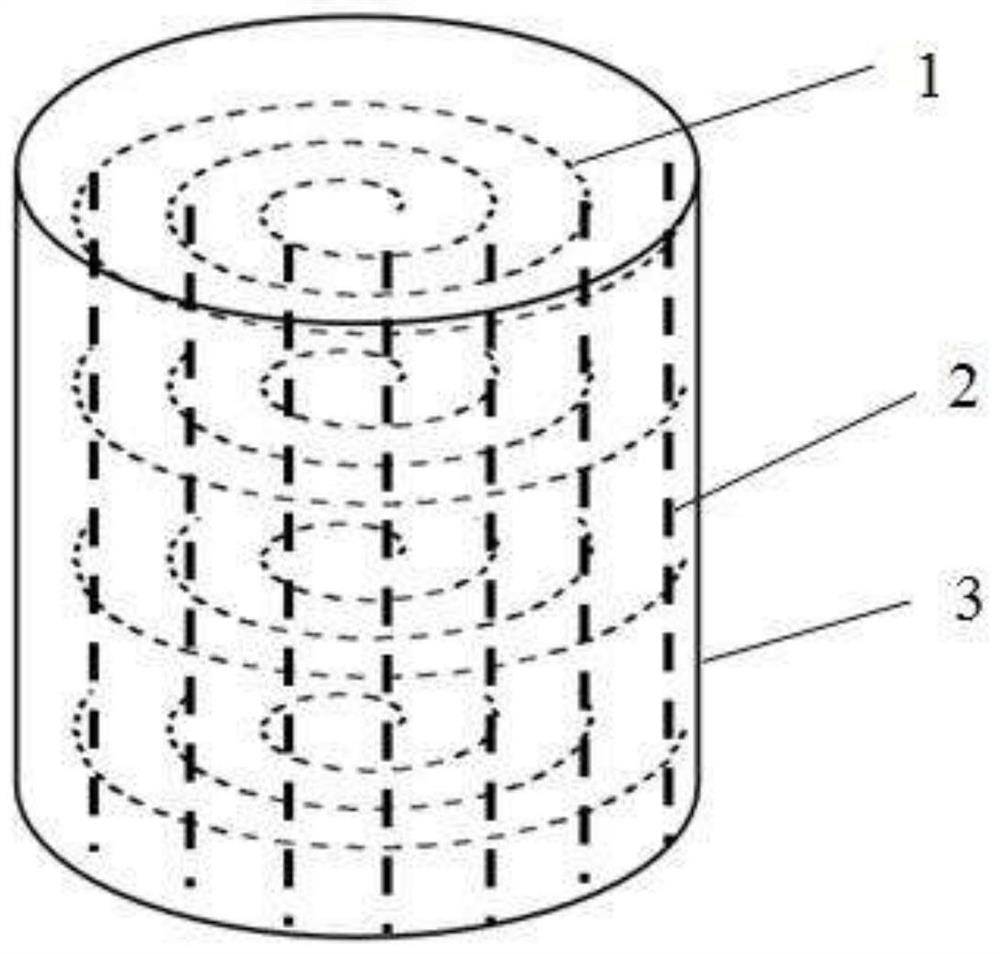

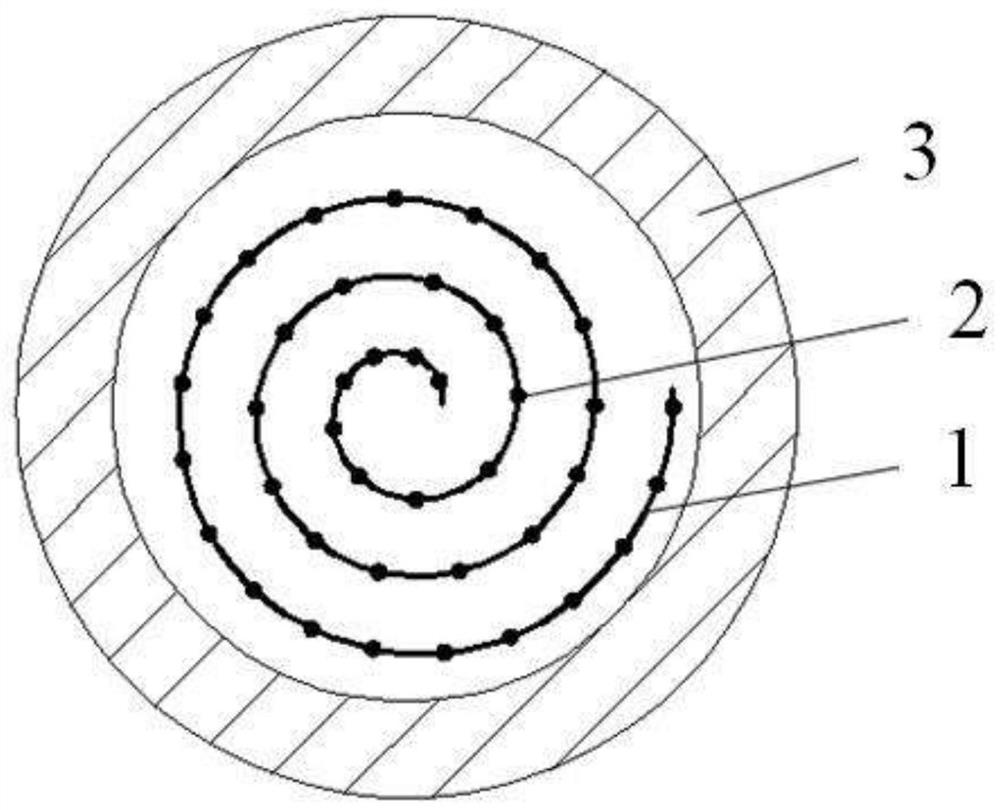

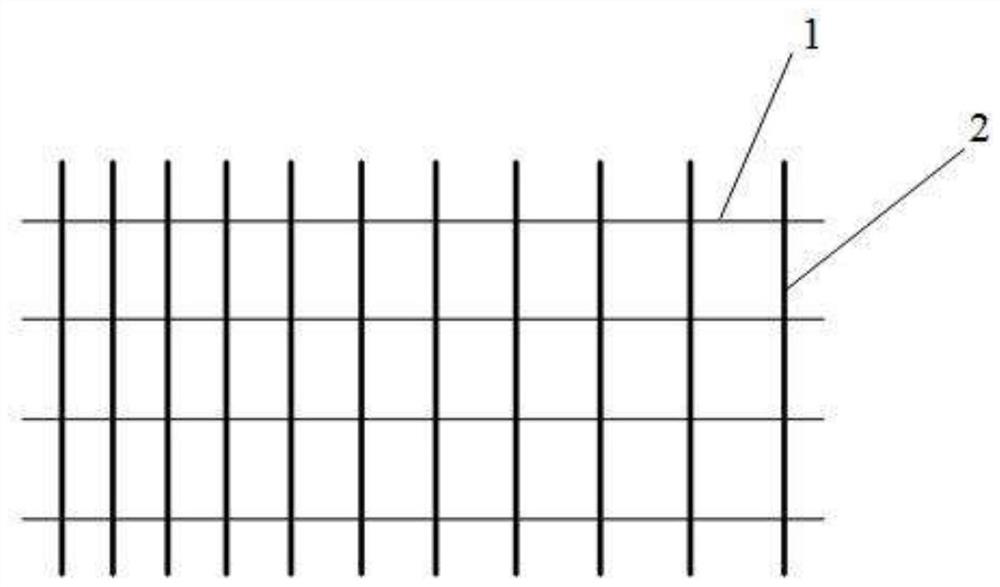

Titanium fiber toughening cold heading die and preparation method thereof

ActiveCN111893405AImprove impact toughnessImprove plasticityForging/hammering/pressing machinesTitanium fiber

The invention discloses a titanium fiber toughening cold heading die. The cold heading die internally comprises a Ti fiber net-shaped framework, wherein Ti fibers forming the Ti fiber net-shaped framework are covered with a TiC layer; the TiC layer is formed by stacking submicron-order TiC particles; micron-order WC particles and Fe binding phases are dispersed and distributed between the Ti fibernet-shaped framework; and the Ti fiber net-shaped framework is formed by connecting a plurality of transverse Ti fibers and longitudinal Ti fibers, the transverse Ti fibers are spiral fibers, and thetransverse Ti fibers are connected with the longitudinal Ti fibers from inside to outside. The invention further discloses a preparation method of the titanium fiber toughening cold heading die. Thetitanium fiber toughening cold heading die prepared through the method does not contain rare metal, and is low in manufacturing cost, high in toughness and wide in application range.

Owner:XIAN UNIV OF TECH

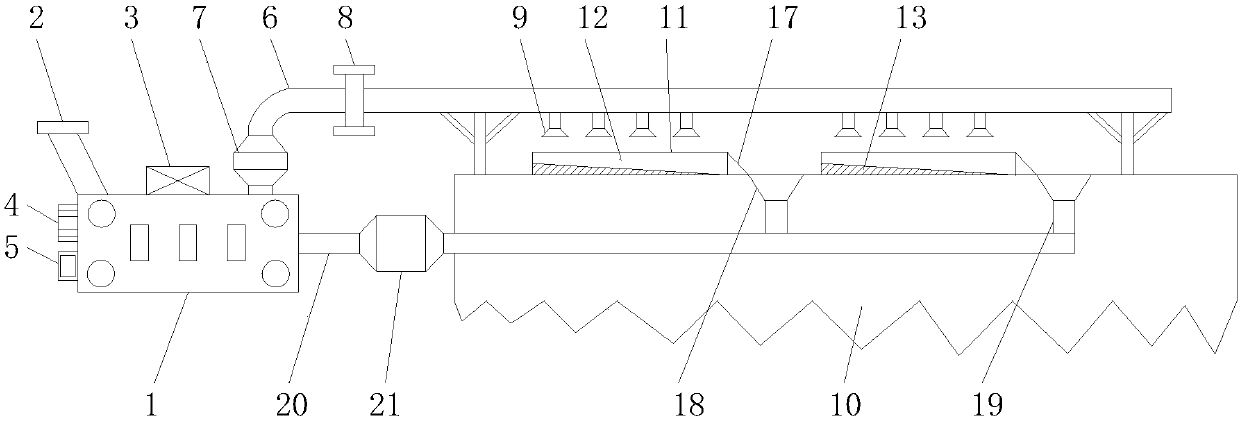

A high-speed cloth cutting device based on lubricating oil drainage and pressing cloth to reduce vibration

ActiveCN110863338BPrevent gravity from tiltingAvoid drippingSevering textilesElectric machineryEngineering

Owner:东营经济技术开发区东汇新能源有限公司

High-speed fabric breaking device based on lubricating oil drainage fabric pressing vibration reduction

ActiveCN110863338APrevent gravity from tiltingAvoid drippingSevering textilesOil canElectric machinery

The invention discloses a high-speed fabric breaking device based on lubricating oil drainage fabric pressing vibration reduction. The high-speed fabric breaking device structurally comprises a left structure and a right structure which are structurally the same and are connected by assembly. The left structure comprises a tool rest, a fabric pressing device, a balance pile, a cutter, a cutter seat frame and a high-speed motor. The fabric pressing device is mounted at the position of the tool rest and presses a fabric when the fabric is conveyed and cut. The fabric pressing device is disassembled when the fabric is replaced. During disassembly, lubricating oil can be transferred to a ball attaching position and stored, and the lubricating oil cannot drop to the fabric, the cutter seat frame or the fabric pressing device when the fabric pressing device is disassembled. During assembly and fixation, the device is fixed by a plate coating device, assembly conformability is improved by theaid of an inclined plate, an inclined spring plate functions in fixing and reinforcing, a pressing plate and a fabric cutting blade can be aligned, vibration and friction of the fabric pressing device generated by cutting of the cutter can be reduced, and the pressing plate cannot be loosened and can more effectively fit with the fabric when pressing the fabric.

Owner:东营经济技术开发区东汇新能源有限公司

Aging-resistant silane cross-linked polyethylene insulating composite material and preparation method thereof

The invention discloses an aging-resistant silane cross-linked polyethylene insulating composite material. The aging-resistant silane cross-linked polyethylene insulating composite material is characterized by being prepared from, by weight, 120-150 parts of low-density polyethylene resin, 1-2 parts of nano-zinc oxide, 10-15 parts of barite powder, 10-15 parts of kaolin, 2-4 parts of linear phenolic resin, 2-3 parts of polypropylene glycol, 0.3-0.5 part of methylene diphenyl diisocyanate, 3-5 parts of castor oil, 0.3-0.5 part of monoglyceride citrate, 0.3-0.5 part of butylated hydroxytoluene, 2-4 parts of ethylene bis stearamide and 3-6 parts of silane complexing agents. The silane cross-linked polyethylene insulating composite material is good in strength and toughness, good in weather resistance, water resistance and corrosion resistance, excellent in aging resistance, long in service life and good in comprehensive performance.

Owner:合肥蓝科新材料有限公司

A kind of titanium fiber toughening cold heading die and preparation method thereof

ActiveCN111893405BImprove impact toughnessImprove plasticityForging/hammering/pressing machinesTitanium fiberCeramic materials

The invention discloses a titanium fiber toughening cold heading mold. The cold heading mold contains a Ti fiber mesh skeleton, and the Ti fibers forming the Ti fiber mesh skeleton are covered with a TiC layer, and the TiC layer is composed of submicron TiC particles. , micron-scale WC particles and Fe binder phase are dispersed between the Ti fiber network framework; Ti fiber network framework is composed of multiple transverse Ti fibers and longitudinal Ti fibers connected, the transverse Ti fibers are helical fibers, and the transverse Ti fibers are helical fibers. The fibers are connected with longitudinal Ti fibers from the inside to the outside. The invention also discloses a method for preparing a titanium fiber toughened cold heading mold. The titanium fiber toughened cold heading mold prepared by the method does not contain rare metals, has low manufacturing cost, high toughness and can be widely used.

Owner:XIAN UNIV OF TECH

Diet formula for treating viral hepatitis

InactiveCN105360790AEasy to manufactureLow priceDigestive systemMammal material medical ingredientsWestern medicineRegimen

The invention provides a diet formula for treating viral hepatitis to solve the problems of long treatment course, high cost, toxic and side effects generated due to excessive administration of medicines, and possible recurrence of present western medicine treatment. The diet formula for treating viral hepatitis comprises, by mass, 8-12 parts of Polygonum multiflorum, 8-12 parts of Viscum coloratum (Kom.) Nakai, 8-12 parts of Rhizoma Sparganii, 8-12 parts of Fructus Gardeniae, 8-12 parts of isatis root, 4-8 parts of Rhizoma curcumae longae, 1-3 parts of ginseng, 28-32 parts of Chinese yam flour and 0.5-1.5 parts of Human Placenta. The diet formula has the advantages of convenient preparation, low price, no toxic or side effects, strengthening effect, and recurrence avoiding.

Owner:李新民

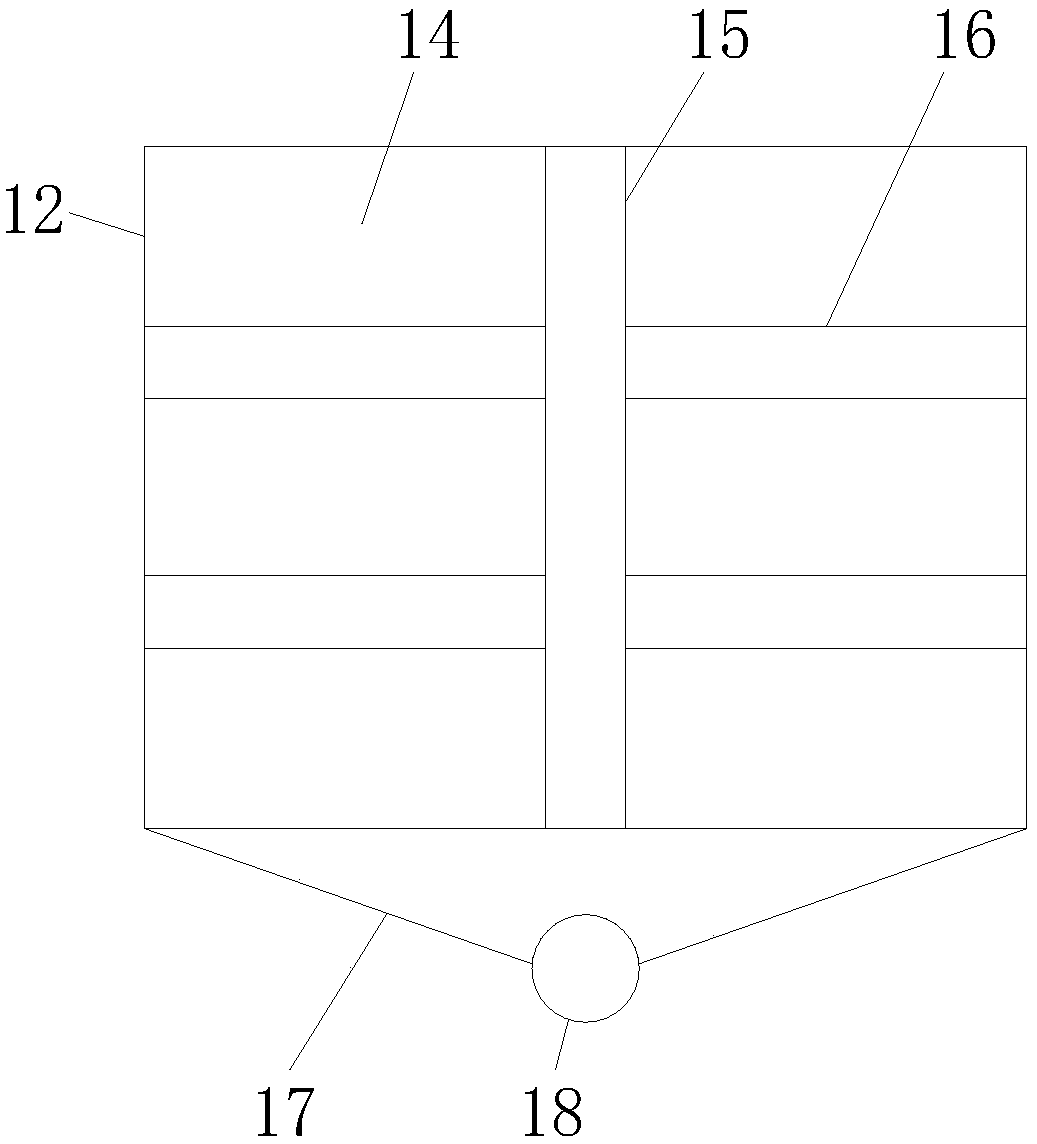

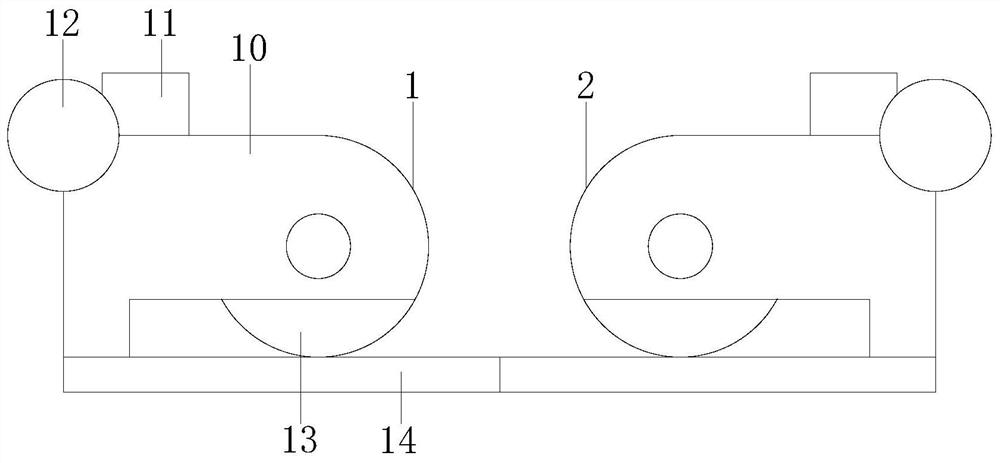

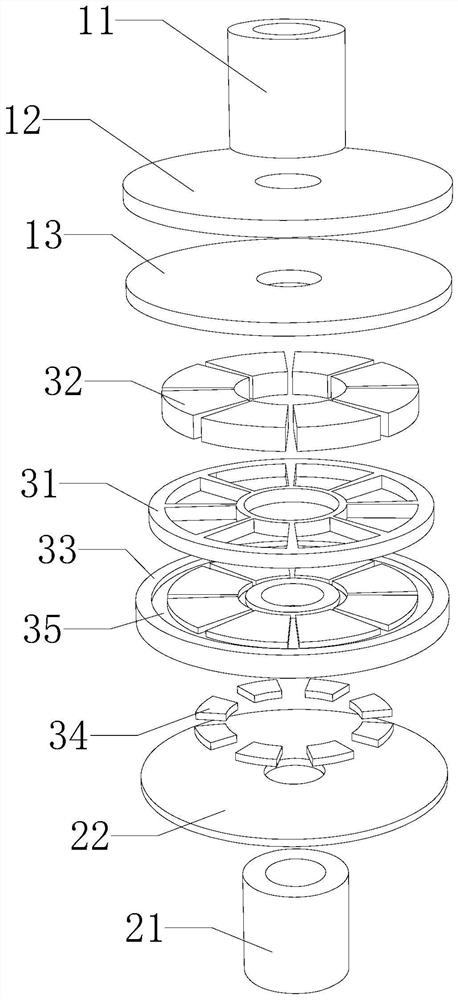

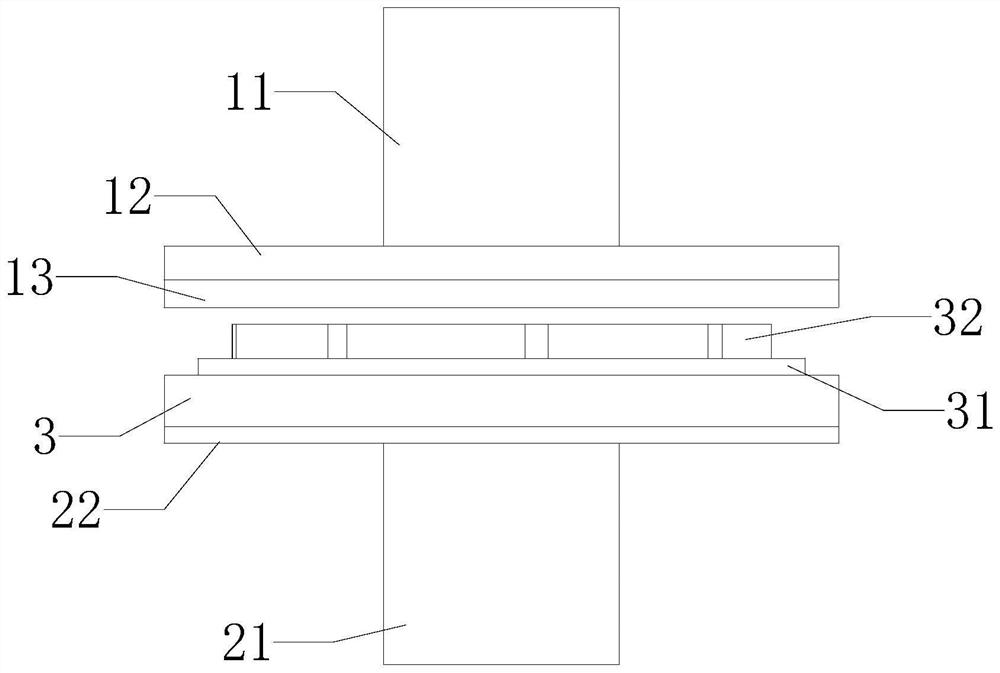

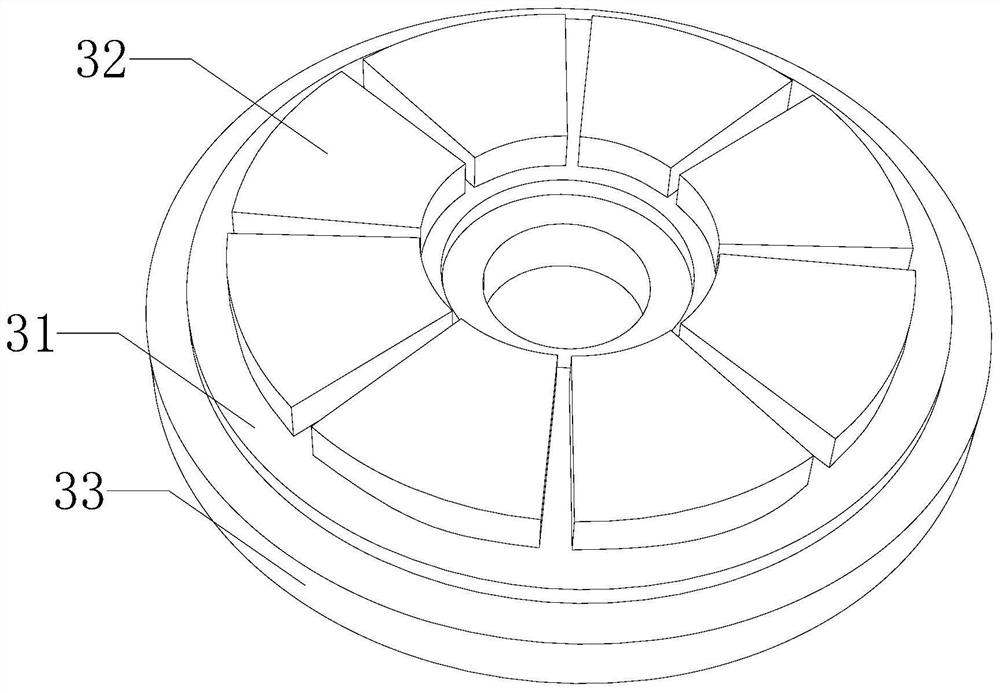

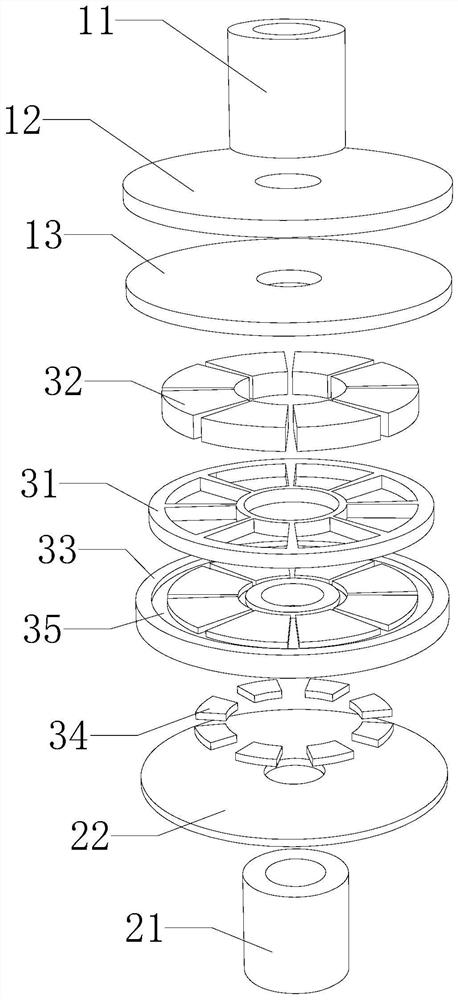

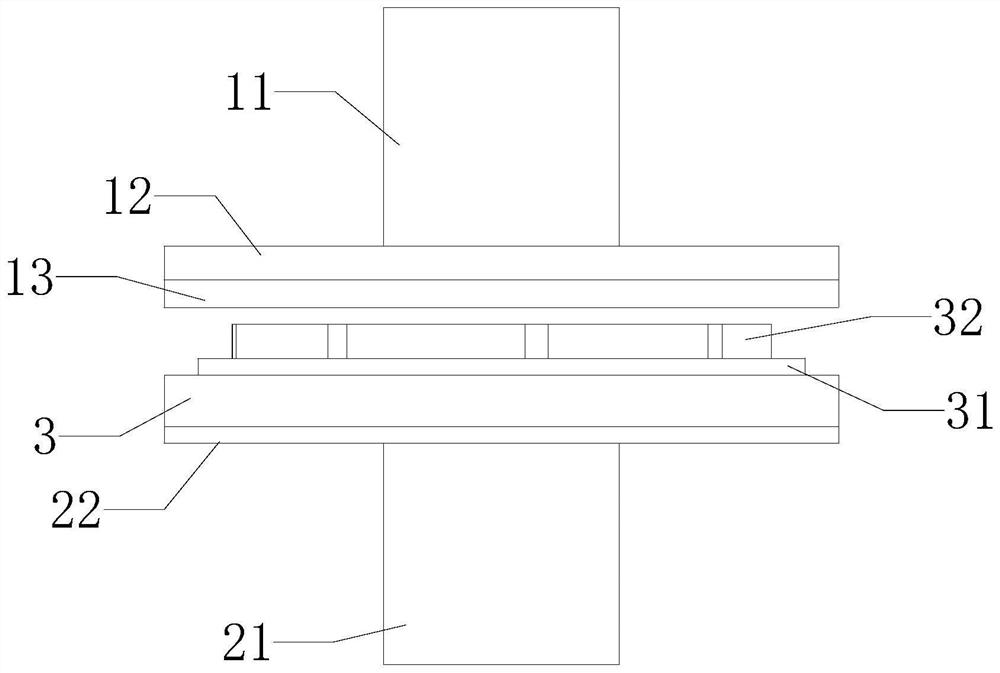

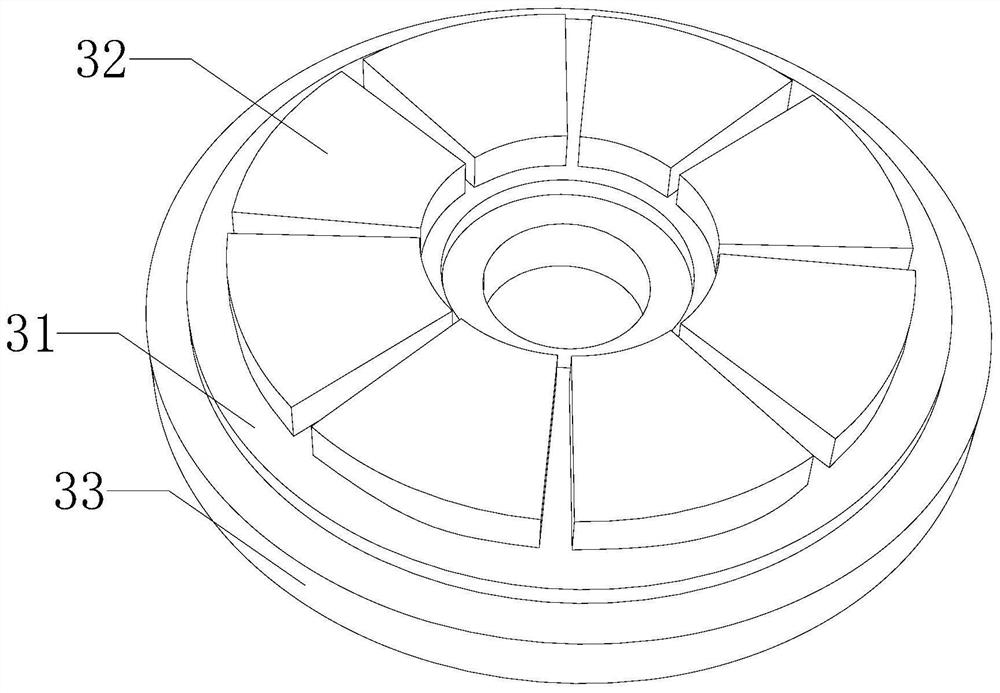

A back iron slotted disk permanent magnet transmission device

ActiveCN113067451BIncrease torqueIncreased local magnetic fieldPermanent-magnet clutches/brakesCouplingMagnetic poles

The invention relates to the technical field of transmission, in particular to a disk-type permanent magnet transmission device with a slotted back iron, which is used for transmitting power between two shaft bodies. The two shaft bodies include shaft body 1 and shaft body 2. The first shaft body and the second shaft body are arranged coaxially. The transmission device includes: top plate, eddy current plate, chassis, and fixing mechanism. The top plate is coaxially fixed on one side of the first shaft body. The vortex disk is coaxially fixed on the side of the top disk facing the second shaft body. The chassis is coaxially fixed on the two sides of the shaft body facing the first side of the shaft body. The fixing mechanism is arranged on the side of the chassis facing the first axle body. The fixing mechanism includes a mounting frame, a plurality of main magnetic poles, a mounting disk, and a plurality of auxiliary magnetic poles. The mounting plate is fixed on the side of the chassis facing the shaft body 1. One side of the mounting plate is provided with a first mounting groove, and the other side is provided with a plurality of mounting grooves two corresponding to the plurality of auxiliary magnetic poles in a circular arrangement of the central axis of the mounting plate. The invention effectively reduces the side magnetic leakage existing in the traditional disc magnetic coupling, thereby increasing the torque that the transmission device can transmit.

Owner:HEFEI UNIV OF TECH

High-weatherability silane-crosslinked polyethylene insulation composite material and preparation method thereof

The invention discloses a high-weatherability silane-crosslinked polyethylene insulation composite material, which is composed of the following raw materials in parts by weight: 120 to 150 parts of low-density polyethylene resin, 2 to 4 parts of linear phenolic resin, 2 to 4 parts of titanium dioxide, 5 to 10 parts of diatomite, 10 to 15 parts of lightly-burned dolomite powder, 0.5 to 1 part of octyl phenol polyoxyethylene ether, 0.3 to 0.5 part of benzotriazole, 2 to 3 parts of polypropylene glycol, 0.3 to 0.5 part of diphenyl-methane-diisocyanate, 1 to 2 parts of Turkey red oil, 2 to 4 parts of tri-octyl tri-meta-benzoate, and 3 to 6 parts of silane coupling agent. The provided composite material has the advantages of high strength and toughness, good waterproof and corrosion-resistant performance, excellent weatherability, high safety, long service life, and wide application range, and is suitable for being used in severe environment.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Disc type permanent magnet transmission device with slotted back iron

ActiveCN113067451AIncrease torqueIncreased local magnetic fieldPermanent-magnet clutches/brakesCouplingMagnetic poles

The invention relates to the technical field of transmission, in particular to a disc type permanent magnet transmission device with slotted back iron, which is used for transmitting power between two shaft bodies. The two shaft bodies comprise a first shaft body and a second shaft body. The first shaft body and the second shaft body are coaxially arranged. The transmission device comprises a top disc, a vortex disc, a bottom disc and a fixing mechanism. The top disc is coaxially fixed to one side of the first shaft body. The vortex disc is coaxially fixed to the side, facing the second shaft body, of the top disc. The bottom disc is coaxially fixed to the side, facing the first shaft body, of the second shaft body. The fixing mechanism is arranged on the side, facing the first shaft body, of the bottom plate. The fixing mechanism comprises a mounting frame, a plurality of main magnetic poles, a mounting disc and a plurality of auxiliary magnetic poles. The mounting disc is fixed to the side, facing the first shaft body, of the bottom disc. A first mounting groove is formed in one side of the mounting disc, and a plurality of second mounting grooves corresponding to the auxiliary magnetic poles are annularly formed in the other side of the mounting disc around the center axis of the mounting disc. Side magnetic leakage existing in a traditional disc type magnetic coupling is effectively reduced, and then the torque capable of being transmitted by the transmission device is improved.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com