A kind of aluminum-based nanocomposite material based on slm forming and its preparation method

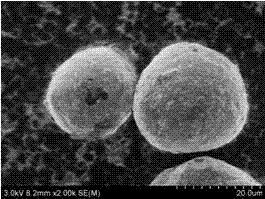

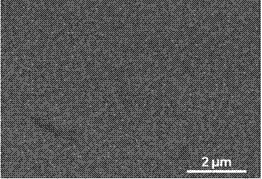

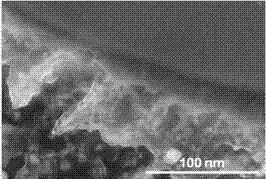

A nanocomposite material and nanocomposite technology, applied in the field of SLM-based aluminum-based nanocomposite material and its preparation, can solve problems such as uneven distribution of reinforced particles, poor wettability, mismatch between process performance and mechanical properties, and achieve The effect of narrow particle size distribution, uniform sphericity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present invention is an aluminum-based nanocomposite material formed based on SLM. The preparation process of the aluminum-based nanocomposite material includes two stages of mechanical high-energy ball milling to prepare aluminum-based nanocomposite powder and SLM forming and curing of aluminum-based nanocomposite powder:

[0058] 1. Preparation of aluminum-based nanocomposite powder by mechanical high-energy ball milling

[0059] The rare earth phase Y (content is 0.3wt%, average particle size is 10 μm) and aluminum matrix phase powder (wherein the content of silicon component is 7.8wt%, and average particle size is 15 μm) powder is mixed, and mixed powder a is obtained; The mixed powder a is placed in a ball mill, and the ball milling tank is continuously evacuated and the residual air is exhausted with argon, and then argon is introduced into the tank, and the air pressure is controlled at 0.5Mpa; the mixed powder a is intermittently ball milled, and the ball mil...

Embodiment 2

[0072] The present invention is an aluminum-based nanocomposite material formed based on SLM. The preparation process of the aluminum-based nanocomposite material includes two stages of mechanical high-energy ball milling to prepare aluminum-based nanocomposite powder and SLM forming and curing of aluminum-based nanocomposite powder:

[0073] 1. Preparation of aluminum-based nanocomposite powder by mechanical high-energy ball milling

[0074] Rare earth phase La (content is 0.5wt%, average particle size is 15um) and aluminum matrix phase (wherein silicon component content is 9wt%, average particle size is 30μm) powder is carried out proportioning mixing, obtains mixed powder a; Mixed powder a is placed in a ball mill, vacuumize the ball mill tank continuously and exhaust the residual air with argon gas, then feed argon gas into the tank, and the air pressure is controlled at 0.5Mpa; perform intermittent ball milling on the mixed powder a, and the ball milling speed is 350r / mi...

Embodiment 3

[0085] The present invention is an aluminum-based nanocomposite material formed based on SLM. The preparation process of the aluminum-based nanocomposite material includes two stages of mechanical high-energy ball milling to prepare aluminum-based nanocomposite powder and SLM forming and curing of aluminum-based nanocomposite powder:

[0086] 1. Preparation of aluminum-based nanocomposite powder by mechanical high-energy ball milling

[0087] Rare earth phase Sm (content is 0.8wt%, average particle size is 12um) and aluminum matrix phase powder (wherein silicon component content is 6.8wt%, average particle size is 20μm) carry out proportioning mixing, obtain mixed powder a; Mix Powder a is placed in a ball mill, the ball mill tank is continuously evacuated and the residual air is exhausted with argon, and then argon is introduced into the tank, and the air pressure is controlled at 0.5Mpa; the mixed powder a is intermittently ball milled, and the ball milling speed is 300r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com