Ultra-thick crack-free aluminum oxide ceramic preparation method based on digital light treatment molding technolog

A technology of alumina ceramics and digital light processing, applied in the field of 3D printing, can solve problems such as inappropriate holding temperature or time, poor cracking, poor mechanical properties of ceramics, etc., achieve low cost, solve cracking, and promote The effect of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 (do not add calcium carbonate powder)

[0043] Weigh 78g alumina powder, 19.66g photosensitive resin (among them, EA 30wt%, PUA 10wt%; HDDA 30wt%, ACMO 14wt%, TMPTA 13wt%; photoinitiator 819 3 wt%), 2.34g dispersant, ball mill Stir evenly to prepare an alumina ceramic slurry with a solid content of 78wt%.

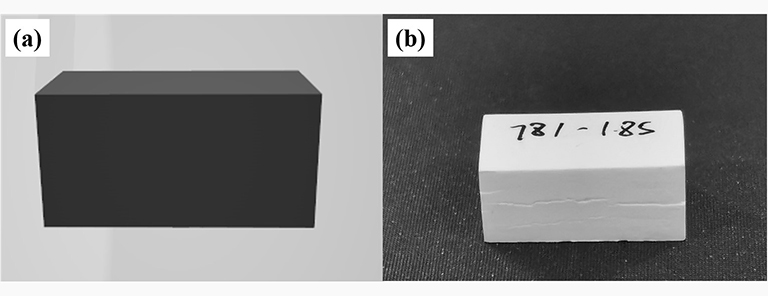

[0044] The three-dimensional graphics drawn by Solid works are designed in a size of 20mm×10mm×10mm, such as figure 1 As shown in -a, import into RayWareC software for slicing, the slice thickness is 20 μm, and export the 3D graphics after slicing as SSJ format files. After adjusting the printer, set the printing parameters, set the curing time of the base layer to 15s, the number of printing layers of the base layer to 5 layers, and the curing time of a single layer to 1.8s. After all preparations are complete, start to print layer by layer. After printing, carefully remove the ceramic green body from the printing platform and wipe off the uncured pas...

Embodiment 2

[0048] Weigh 77.22g of alumina powder, 0.78g of calcium carbonate powder, 19.66g of photosensitive resin, and 2.34g of dispersant, and mix them uniformly by ball milling to prepare an alumina ceramic slurry with a solid content of 78wt%.

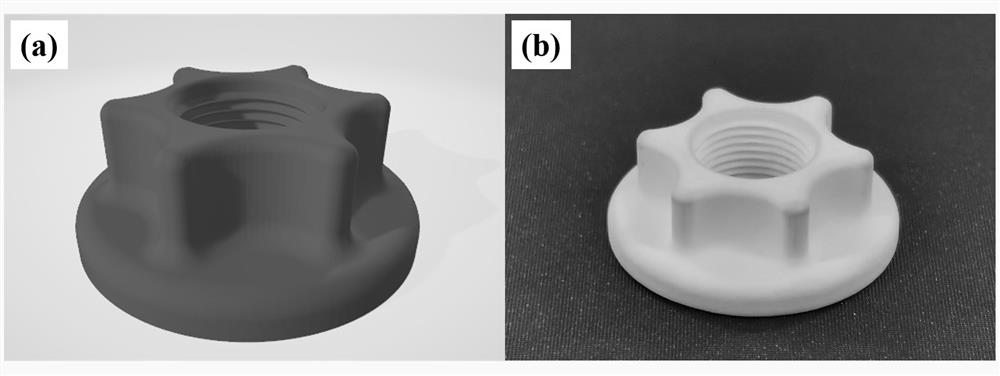

[0049] Using the 3D graphics drawn by Solid works, the size of the nut is designed to be 30mm×30mm×12mm, as attached figure 2 As shown in -a, import it into RayWareC software for slicing, select the slice thickness as 20 μm, and export the 3D graphics after slicing as SSJ format files. After adjusting the printer, set the printing parameters, set the curing time of the base layer to 15s, the number of printing layers of the base layer to 5 layers, and the curing time of a single layer to 1.8s. After all preparations are complete, start to print layer by layer. After printing, carefully remove the ceramic green body from the printing platform and wipe off the uncured paste on the surface with alcohol.

[0050] Degrease and sinter the cerami...

Embodiment 3

[0052] Weigh 76.44g of alumina powder, 1.56g of calcium carbonate powder, 19.66g of photosensitive resin, and 2.34g of dispersant, and mix them uniformly by ball milling to prepare an alumina ceramic slurry with a solid content of 78wt%. Other steps are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com