Butterfly-type cable-stayed bridge system

A cable-stayed bridge and system technology, applied to cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of increased cable force of the main span cable-stayed cables, large stress amplitude of end anchor cables, and increased displacement of the tower top, etc., to achieve The effect of reducing the amount of material, reducing the force, and reducing the deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

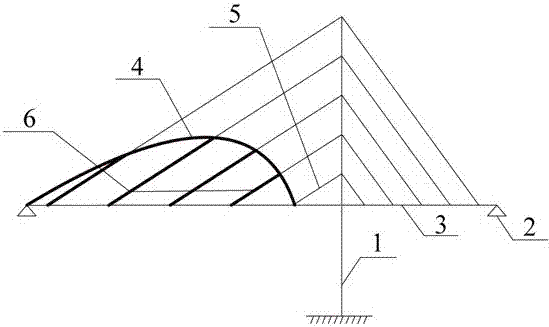

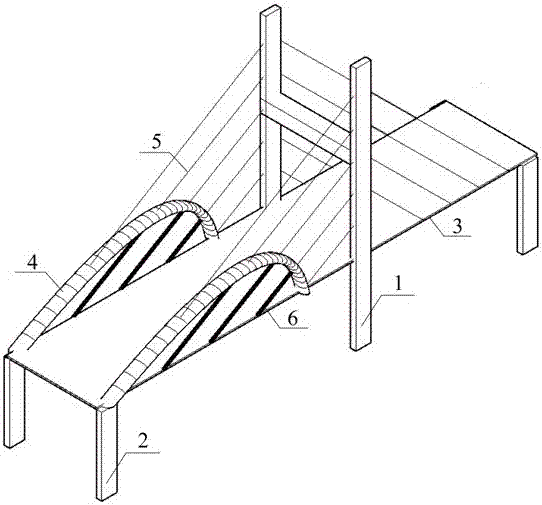

[0021] Embodiment 1: Taking a single-tower cable-stayed bridge as an embodiment, figure 1 It is a schematic diagram (elevation view) of the main structure of the bridge of the present invention, and the cooperation system includes a bridge tower 1, side piers 2, main girder 3, asymmetric curved arch 4, stay cables 5 and inclined suspenders 6.

[0022] The stay cables 5 and the inclined suspenders 6 distributed along the longitudinal direction play the role of elastic support for the main girder 3 . Outside the area of the asymmetric curved arch 4, the two ends of the stay cables 5 are respectively anchored on the bridge tower 1 and the main girder 3; while in the area of the asymmetric curved arch 4, the oblique suspenders 6 are obliquely anchored to the asymmetric curved arch 4 On the arch rib, the oblique suspension rod 6 and the stay cable 5 are anchored at the same point on the arch rib of the asymmetric curved arch 4, and are located on the same straight line, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com