Installing and fixing structure of suspension torsion bar of torsion beam of automobile

A technology of fixed structure and torsion beam, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve problems such as strength not meeting design requirements, poor welding performance, welding cracking, etc., to improve stress concentration and connection strength. , the effect of reducing the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

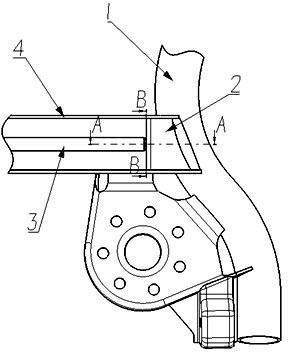

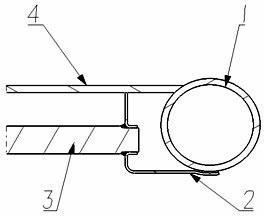

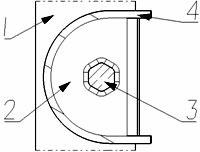

[0013] Embodiment one: see figure 1 , figure 2 and image 3 The shown installation and fixing structure of a torsion beam suspension torsion bar for an automobile includes an intermediate bracket 2 and a torsion bar 3; Connect, the top of the right end of the horizontal part of the intermediate bracket is fixedly connected with one side of the longitudinal arm 1, and the right end of the torsion beam 4 is fixedly connected with the other side of the longitudinal arm 1; There are hexagonal flanging holes, and the right end of the torsion bar is correspondingly a hexagonal structure, and the hexagonal structure is in interference fit with the hexagonal flanging holes in the middle of the vertical part of the middle bracket, and is fixedly connected by welding .

Embodiment 2

[0014] Embodiment two: see figure 1 , figure 2 and image 3 The shown installation and fixing structure of a torsion beam suspension torsion bar for an automobile includes an intermediate bracket 2 and a torsion bar 3; Connect, the top of the right end of the horizontal part of the intermediate bracket is fixedly connected with one side of the longitudinal arm 1, and the right end of the torsion beam 4 is fixedly connected with the other side of the longitudinal arm 1; There is a quadrilateral flanging hole, and the right end of the torsion bar is a quadrilateral structure correspondingly, and the quadrilateral structure is in interference fit with the quadrilateral flanging hole on the middle part of the vertical part of the intermediate bracket, and is fixedly connected by welding.

[0015] The torsion bar and the intermediate bracket are assembled with interference, and then strengthened by carbon dioxide shielded welding. The intermediate bracket is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com