Technology for hoisting web of girder by using rail-mounted gantry crane

A main girder web and rail crane technology, which is applied in the field of rail cranes, can solve the problems of costing a lot of manpower and material resources, and achieve the effects of wide applicability, ensuring construction safety, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

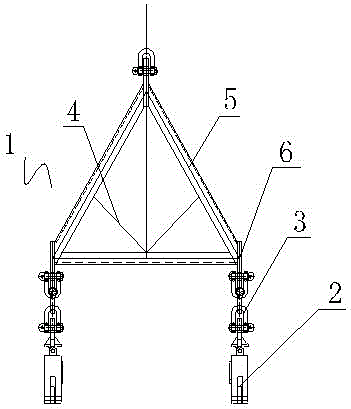

[0022] A kind of hoisting process of main girder web plate of rail crane mainly includes: triangular spreader 1, vertical lifting steel plate lifting clamp 2, 5t shackle 3, triangular spreader 1 is triangular in shape and hollow in the middle, and triangular spreader 1 The three sides are made of channel steel 5, and the three vertices of the triangle spreader 1 are welded and fixed with a transition plate 6, and a connection hole is opened in the middle of the transition plate 6, and the lifting point can be reasonably selected according to different shapes of the plate and matched with the corresponding The spreader has simple structure and wide applicability. In addition, a plurality of reinforcing ribs 4 are welded and fixed inside the triangle of the triangle spreader ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com