High-speed heavy mechanical snow removing equipment and control method

A technology of heavy machinery and equipment, which is applied in snow surface cleaning, cleaning methods, construction, etc. It can solve the problems of small size, inability to adapt to complex road conditions, and low speed, so as to improve service life, improve elasticity, and reasonable snow throwing angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

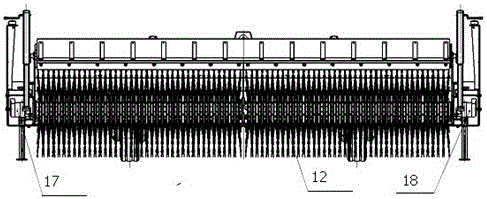

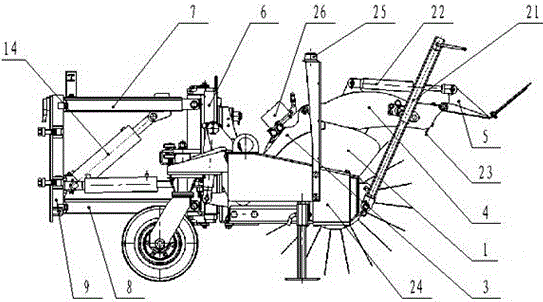

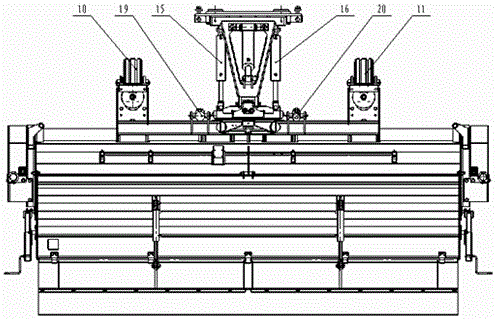

[0033] to combine figure 1 , figure 2 and image 3 , a high-speed heavy machinery snow removal equipment, comprising: a main frame device, a front frame device, a four-bar linkage device, a road wheel device, a brush core device, a hydraulic device and a lifting device;

[0034] The main frame device includes a rear frame 3, a left side bracket 1 and a right side bracket 2; the front frame device includes a front shield 4 and a small snow shield 5; The upper frame 7, the lower frame 8 of the propulsion frame and the base 9 of the propulsion frame; the road wheel device includes a first tire assembly 10 and a second tire assembly 11; the brush core device includes a transmission shaft 12 and bristles; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com