Wheel-rail transfer mud system

A mud and transfer technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of difficult layout of pipelines between tanks, incomplete discharge of mud, and inability to achieve centralized discharge of cuttings, etc. The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

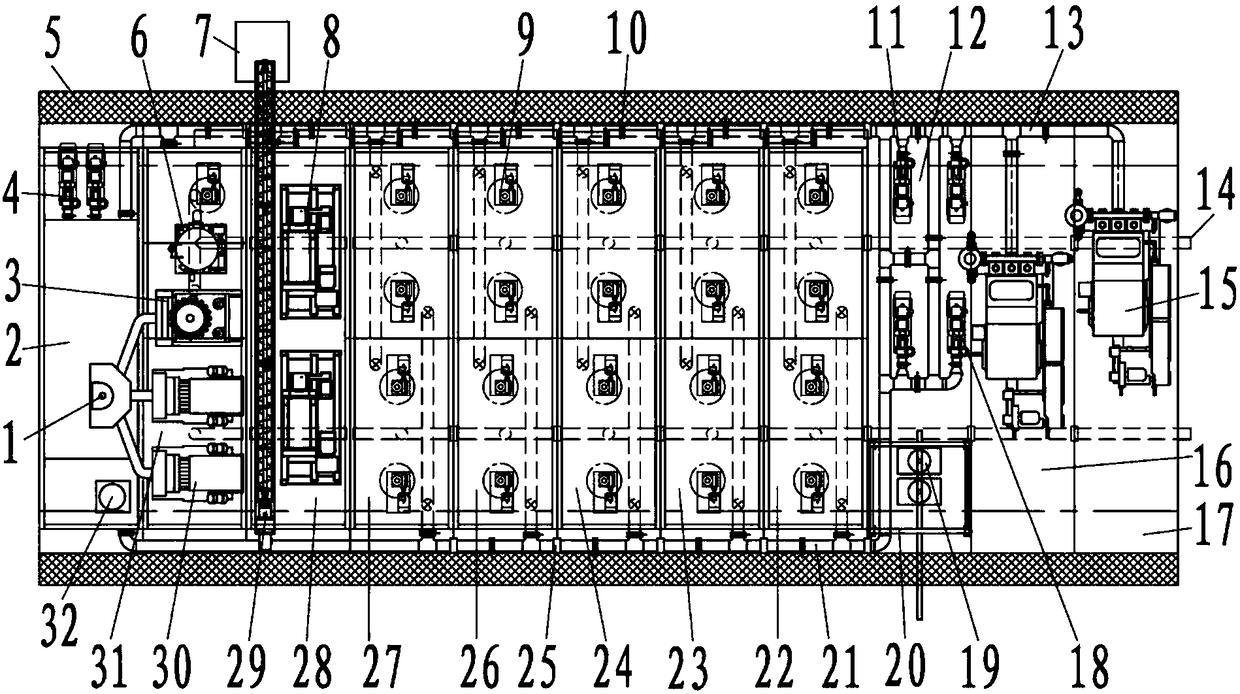

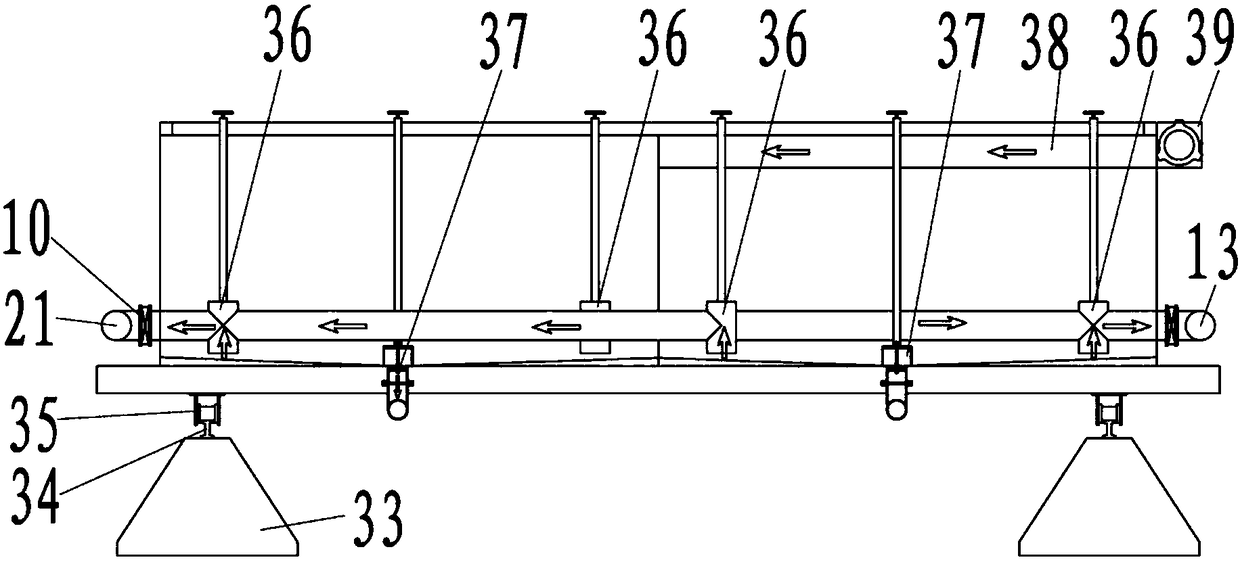

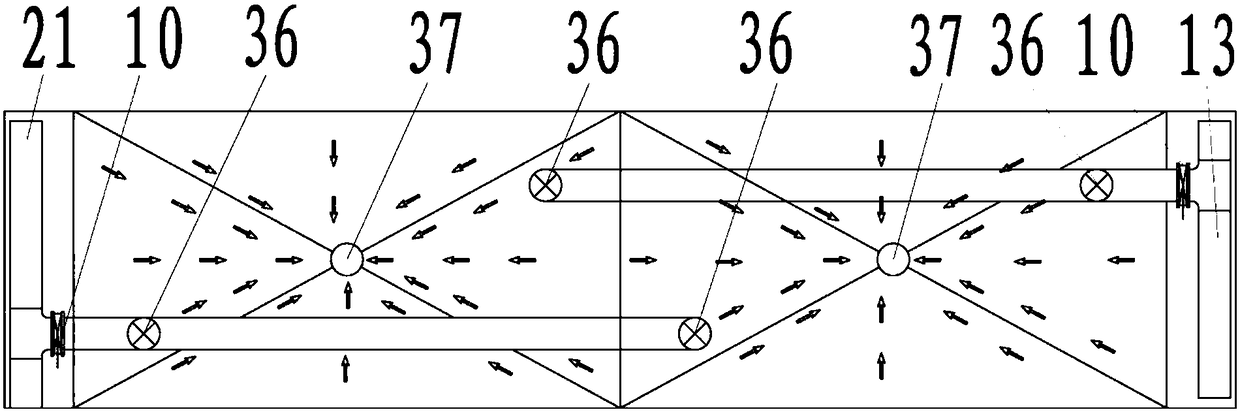

[0026] refer to figure 1 , figure 2 , Figure 5 , the structure of the present invention is, comprise the water tank 2 that closes discharge with zero clearance, vibrating screen tank 31, purification skid 28, intermediate tank 27, 1# reserve tank 26, 2# reserve tank 24, 3# reserve tank 23, suction Tank 22, mixing skid 12, mud pump skid Ⅰ 16, mud pump skid Ⅱ 17, above-mentioned water tank 2, vibrating screen tank 31, purification skid 28, intermediate tank 27, 1# reserve tank 26, 2# reserve tank 24, 3# The storage tank 23, the suction tank 22, the mixing skid 12, the mud pump skid I 16, and the mud pump skid II 17 are respectively equipped with respective roller assemblies 35 on the lower end surfaces, and all the roller assemblies 35 are placed on the guide rail 34 in turn, and the guide rail 34 is installed On the guide rail support 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com