Internal-tight type moment pressure plate bolt

An inner-tightening, pressure plate technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of damaged wire cores and inconvenient use of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

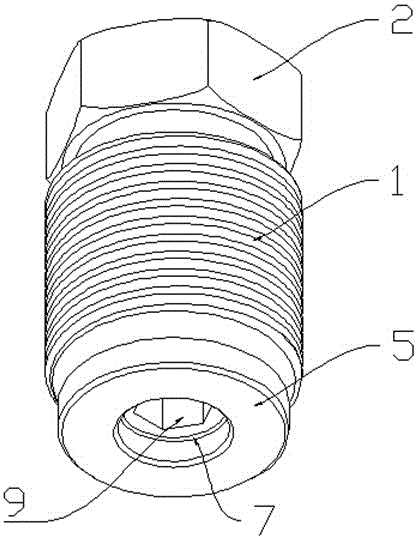

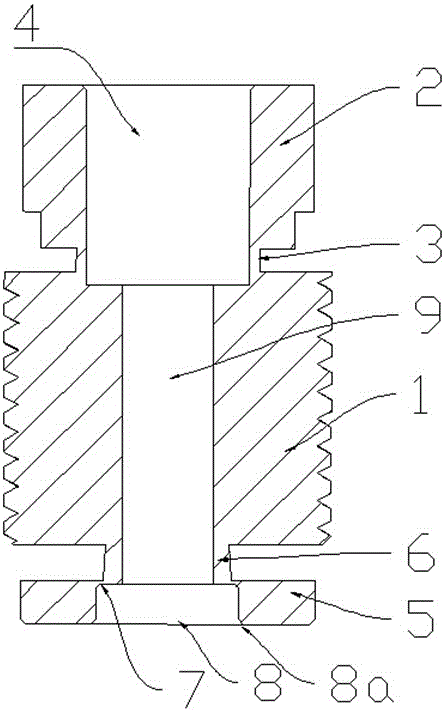

[0015] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings.

[0016] See attached Figures 1 to 2 , the present invention includes a bolt main body 1, an outer hexagonal bolt head 2 is arranged on the top of the main body 1, the main body 1 and the outer hexagonal bolt head 2 are connected through a fracture part 3, and the outer hexagonal bolt head 2 and the fracture part 3 are connected internally. The inner hole 4 is characterized in that: a pressure plate 5 is provided under the main body 1, the main body 1 and the pressure plate 5 are connected by a limiting part 6, and a breaking part is provided between the limiting part 6 and the pressure plate 5 Two 7, the strength of the fracture part two 7 is smaller than that of the fracture part one 3.

[0017] Further, the pressure plate 5 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com