Joint part of a fire hose

一种消防水带、配件的技术,应用在管子/管接头/管件、软管连接装置、机械设备等方向,能够解决推环22不能接触等问题,达到优良操作性、迅速消防活动、避免乱跳的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

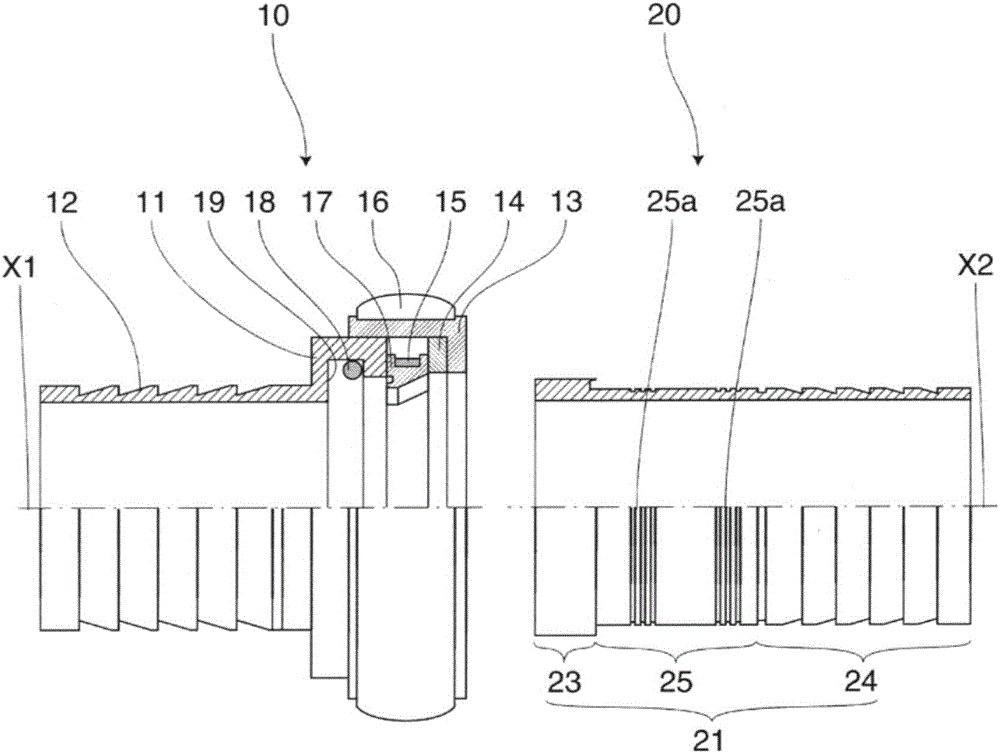

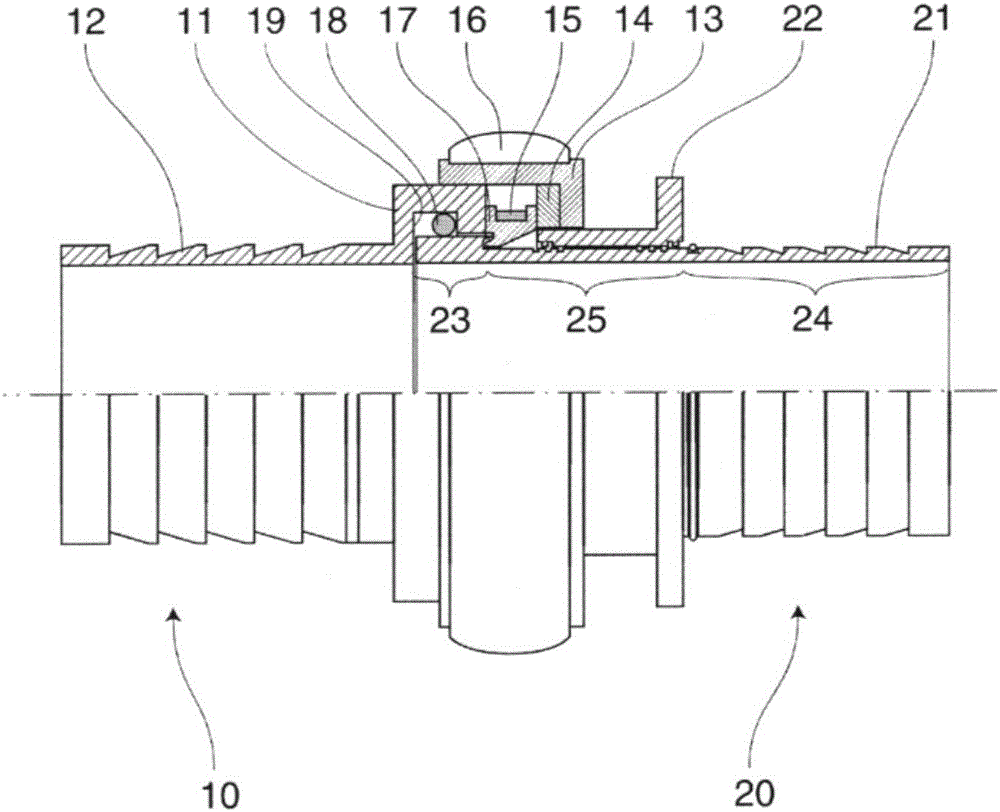

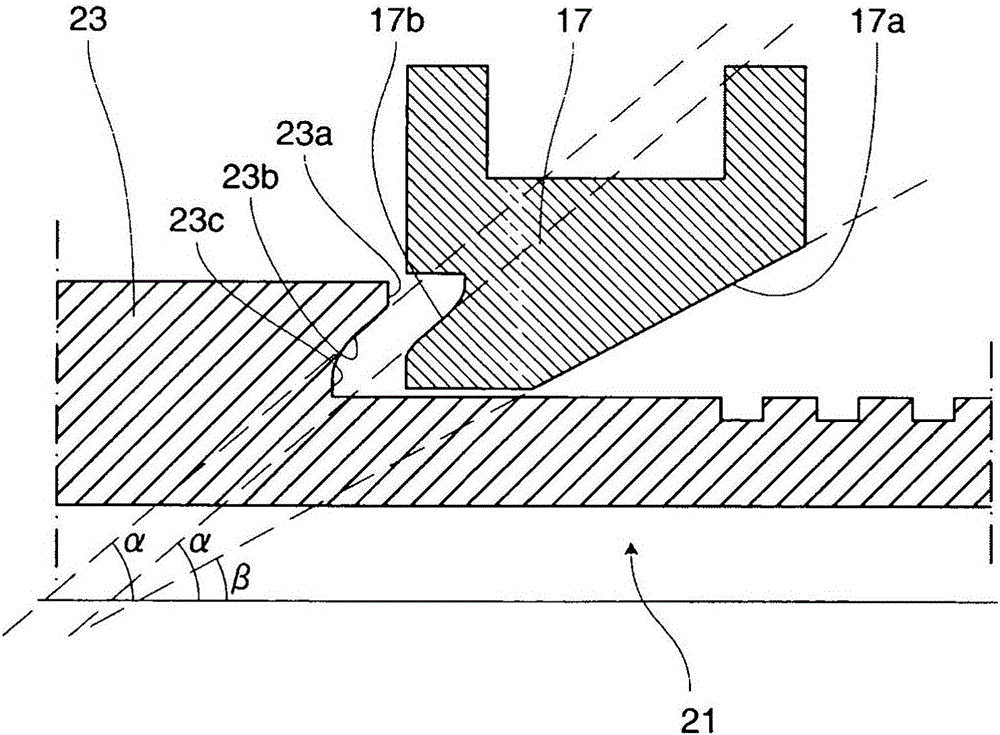

[0070] Next, according to the accompanying drawings, a joint fitting of a fire hose according to an embodiment of the present invention will be described.

[0071] figure 1 It is a half-sectional view of the state in which the joint fittings of the fire hose of this embodiment are disengaged (but the push ring is not shown), figure 2 It is a half-sectional view of a state in which the coupling fittings of the fire hose of this embodiment are combined, image 3 It is a sectional view of the main parts of the joint fittings of the fire hose of this embodiment, Figure 4 It is a half-sectional view of the push ring used for the combination fitting of the fire hose of this embodiment, Figure 5 It is a cross-sectional view of main parts showing the operating state of the coupling fitting of the fire hose of this embodiment. In addition, members having the same functions as those in the conventional example are assigned the same reference numerals, and a part of description th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com