Electric heating constant-temperature air blowing drying box

A technology of blast drying box and drying box, which is applied in the direction of drying solid materials, dry goods handling, drying room/container, etc. It can solve the problems of difficult control of inner tank temperature, inconvenient taking of experimental objects, and slow heating of inner tank, etc. Achieve the effect of simple structure, wide application range and uniform internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

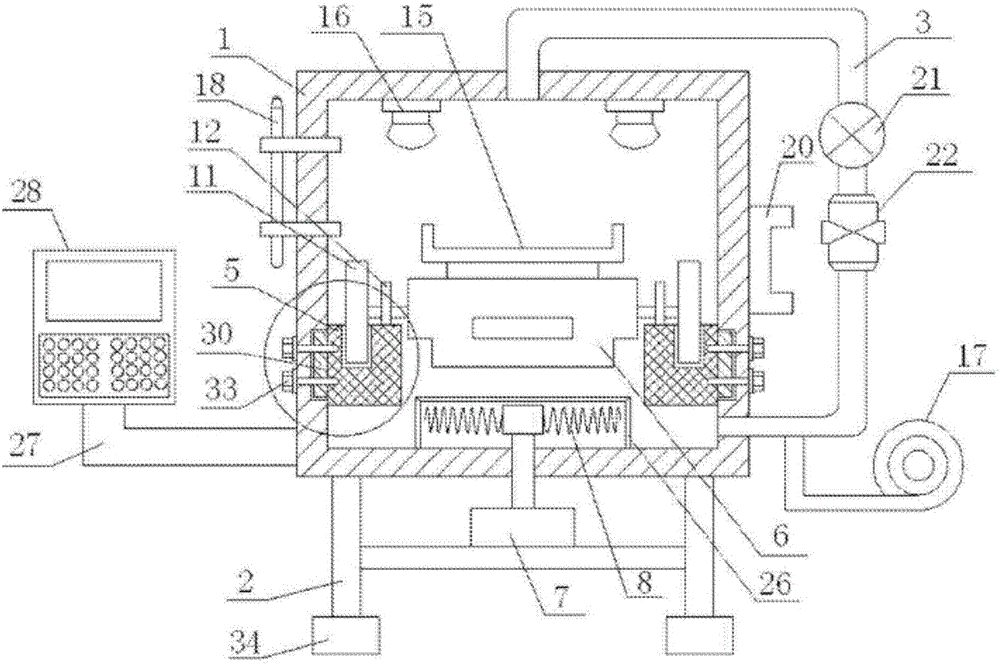

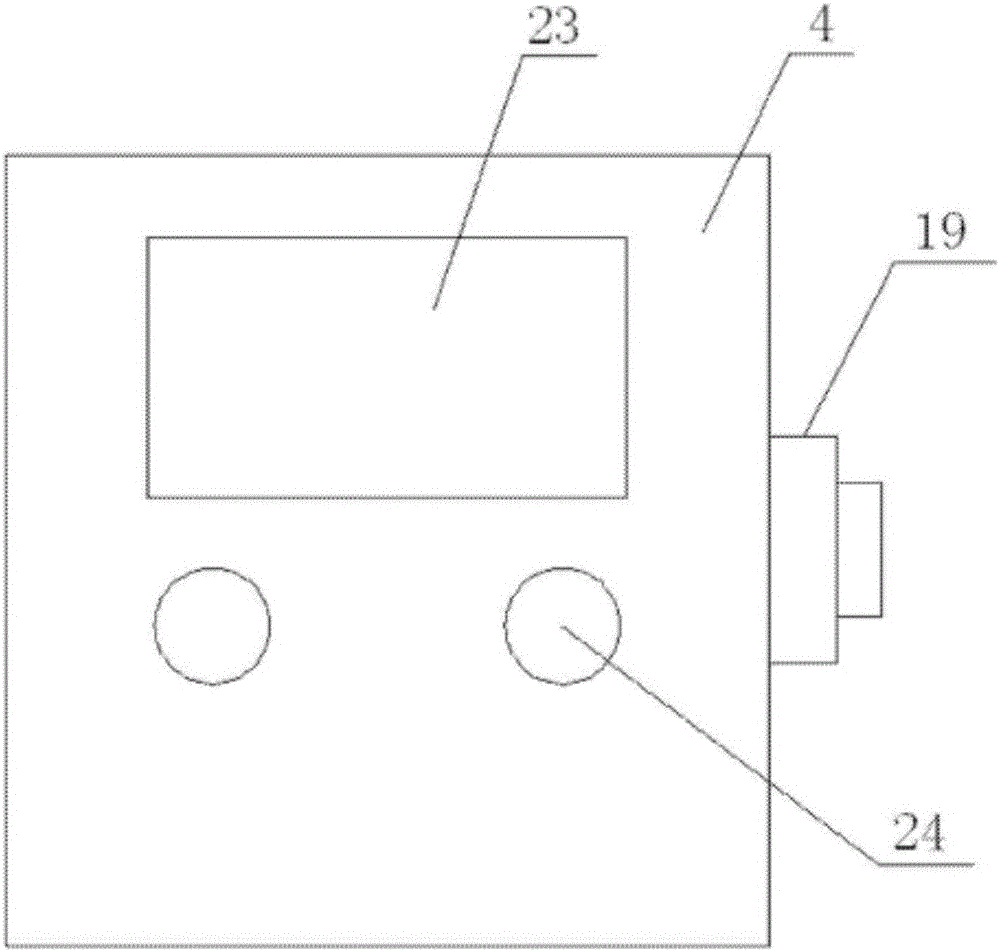

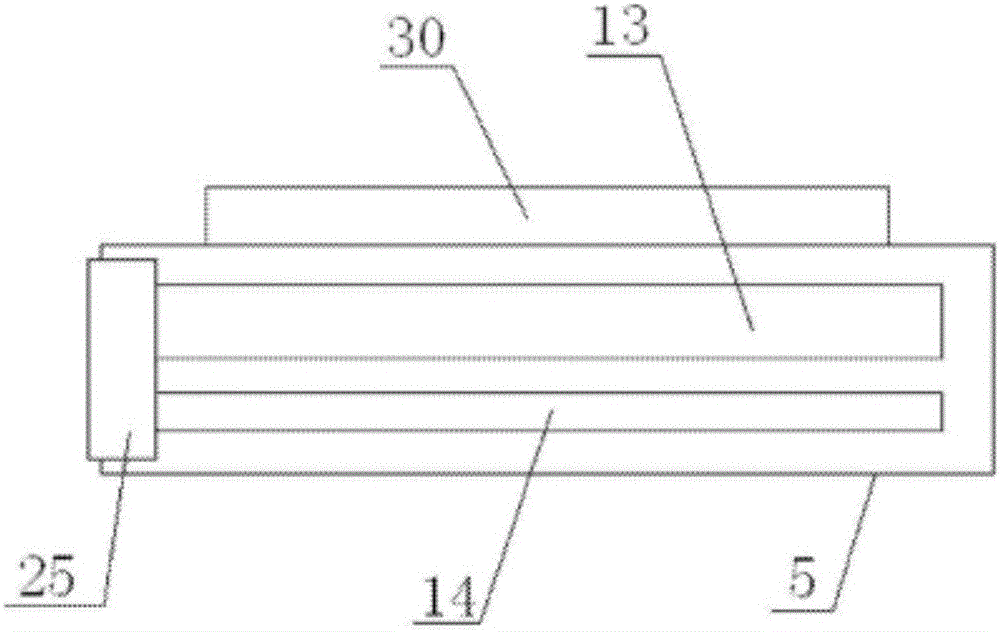

[0017] refer to Figure 1 to Figure 5 A kind of electric heating constant temperature blast drying box shown, comprises drying box body 1 and frame 2, and the circulation pipe 3 that is arranged on drying box body 1, and the box door 4 that is arranged on drying box body 1, and symmetrical Two fixing parts 5 arranged on the inner wall of the drying box body 1, and a support plate 6 arranged in the drying box body 1, the drying box body 1 is arranged on the frame 2, and the frame 2 is provided with a heating The heater 7, the output end of the heater 7 extends to the inner bottom of the drying box body 1, and the output end of the heater 7 extending to the inner bottom of the drying box body 1 is provided with a heating wire ring 8, and the support plate 6 has two Two first rotating shafts 9 and two second rotating shafts 10 are provided in lateral symmetry, large rollers 11 are provided on the two first rotating shafts 9, small rollers 12 are provided on the two second rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com