Device for measuring displacement and deformation of high-temperature object on basis of structured light and digital speckles

A technology for digital speckle and high-temperature objects, which is applied in the optical field and can solve problems such as difficult to strategic long-distance high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not relevant to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

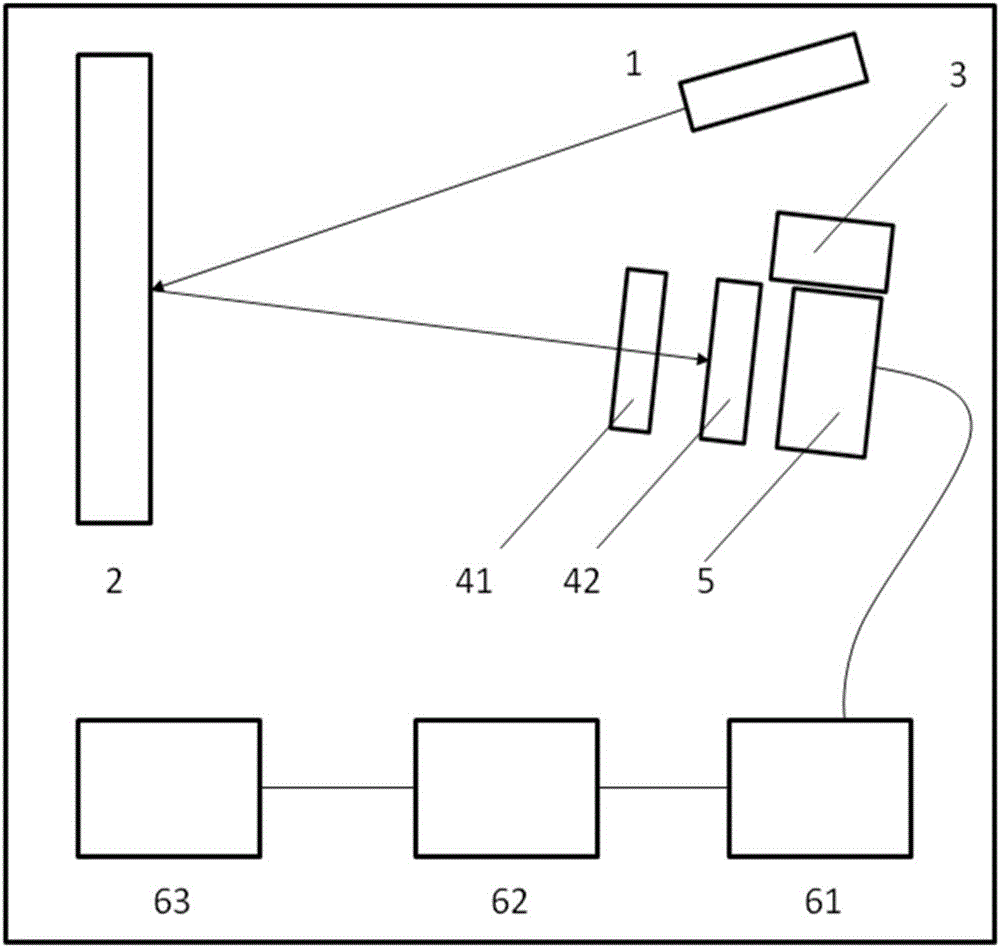

[0030] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of the device described in the embodiment of the present invention, which may specifically include:

[0031] Structured light laser 1, mainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com