Paper feeding sensor of miniprinter

A micro-printer and sensor technology, which is applied to printing devices, optical devices to transmit sensing components, printing, etc., can solve the problems of insufficient reflected light intensity, detection failure, etc., achieve high consistency, improve service life, and improve response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

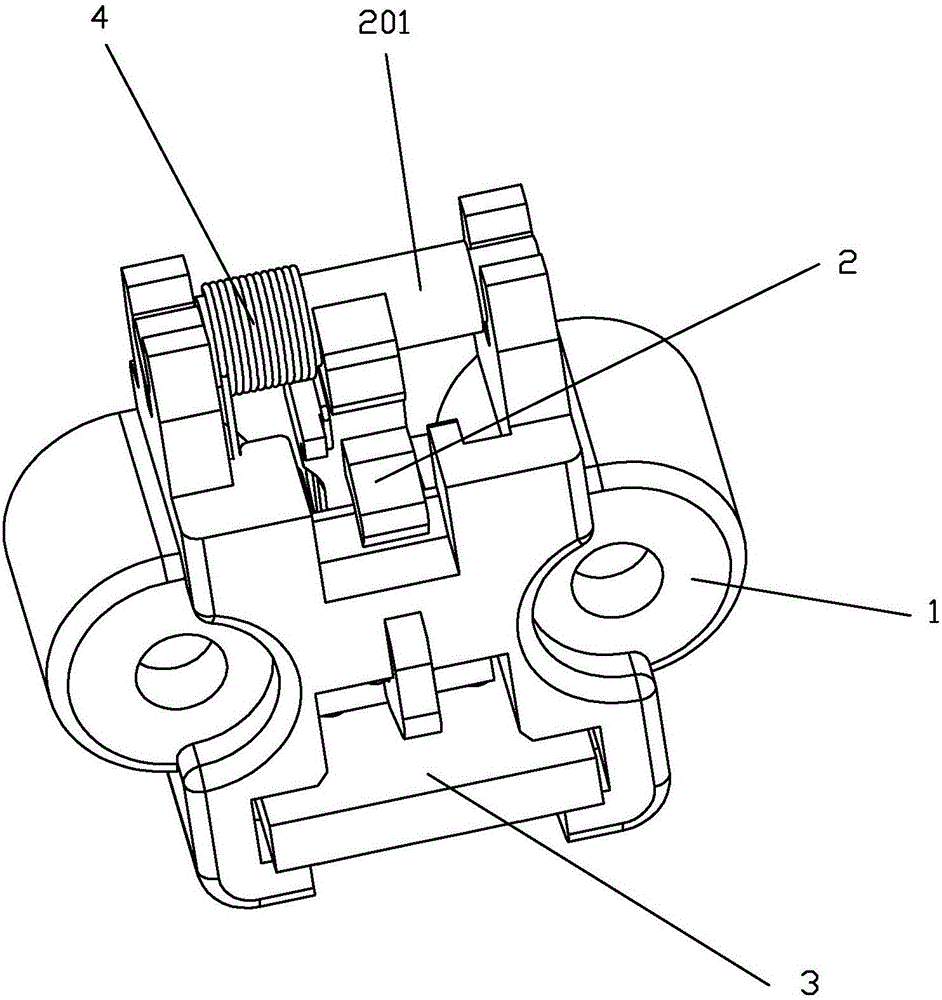

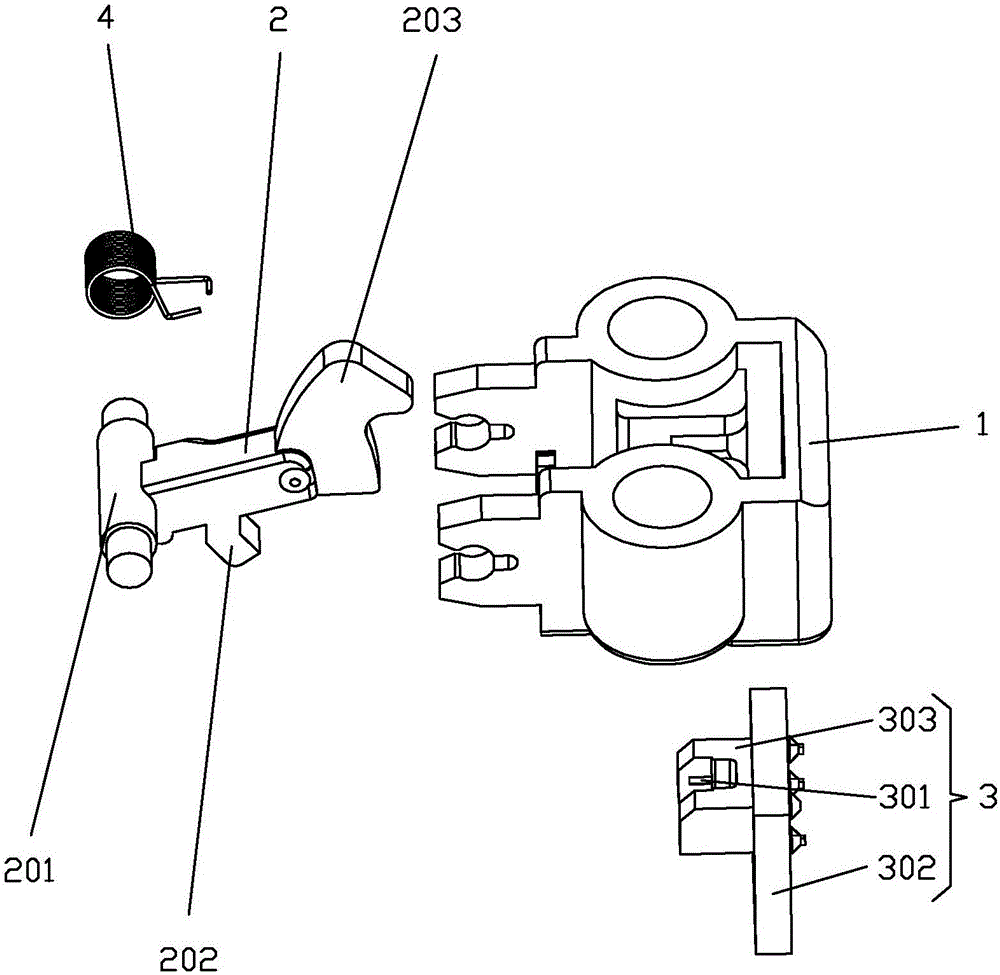

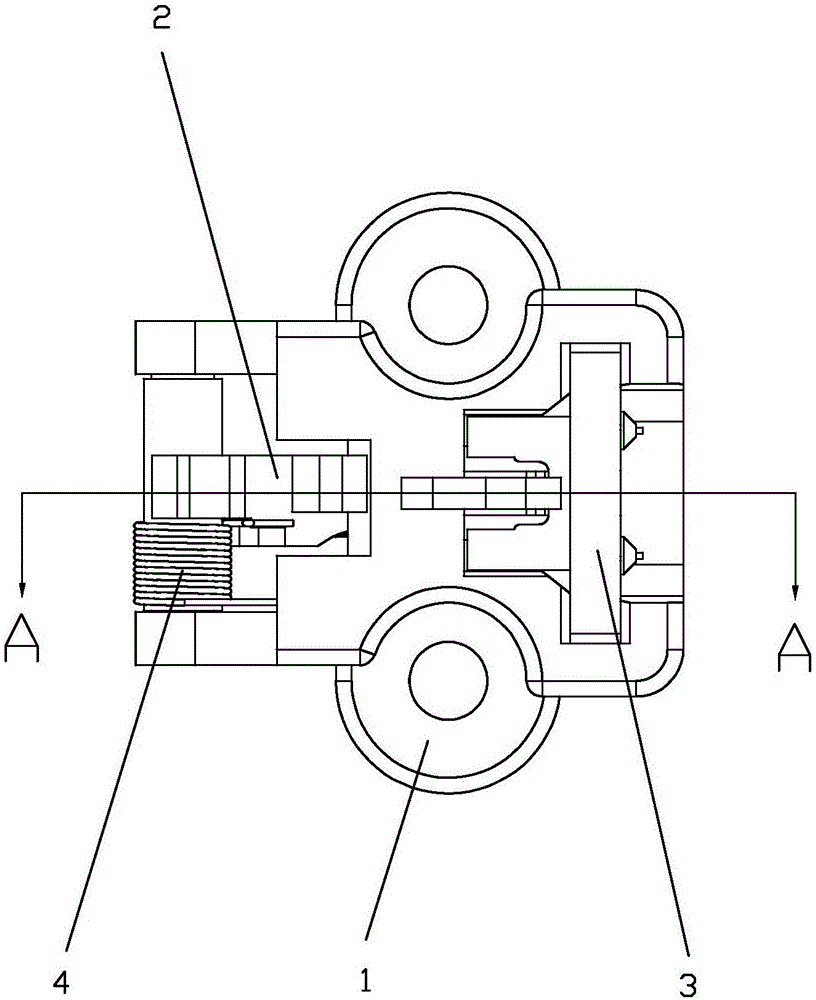

[0019] refer to Figure 1 to Figure 5 , a micro-printer paper feed sensor, including a mounting frame 1 connected to the printer core, a contact arm 2, a bracket 3 equipped with a photoelectric sensor, one end of the contact arm 2 is provided with a rotating shaft 201 perpendicular to the contact arm 2, The contact arm 2 is hinged at one end of the installation frame 1 through a rotating shaft 201, and a torsion spring 4 is set on the rotating shaft 201. One of the two positioning ends of the torsion spring 4 is clamped on the contact arm 2, and the other is clamped on the mounting bracket. on the frame 1; the bracket 3 is installed on the mounting frame 1 and is provided with a photosensitive channel 301, the lower side of the contact arm 2 is provided with a limiting block 202, and the lower end of the mounting frame 1 is provided with a limiting surface 101, and the limiting The block 202 cooperates with the limiting surface 101 so that the lower side of the contact arm 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com