A Method for Evaluating Solid Phase Mass Flow in Dense Phase Pneumatic Conveying Systems

A pneumatic conveying system and mass flow technology, applied in indirect mass flowmeters, mass flow measurement devices, etc., can solve the problem of inability to evaluate solid mass flow in real time, the impact of calibration results, and the inability of gas-solid two-phase flow to be suitable for dense-phase pneumatic conveying systems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The method for evaluating the solid phase mass flow rate of the dense-phase pneumatic conveying system in this embodiment takes the dense-phase pneumatic conveying of pulverized coal in the entrained-bed pulverized coal pressurized gasification process as an example.

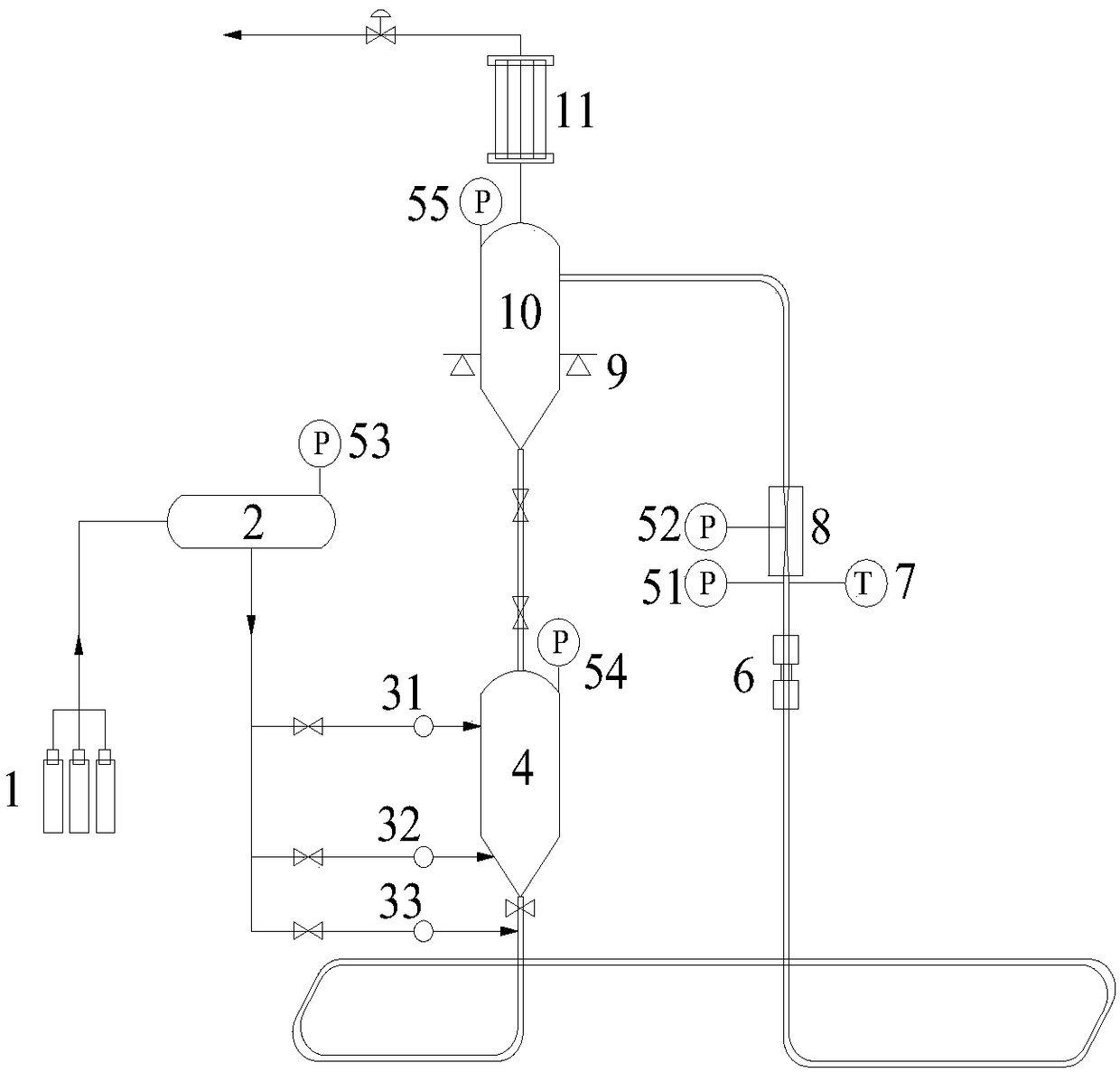

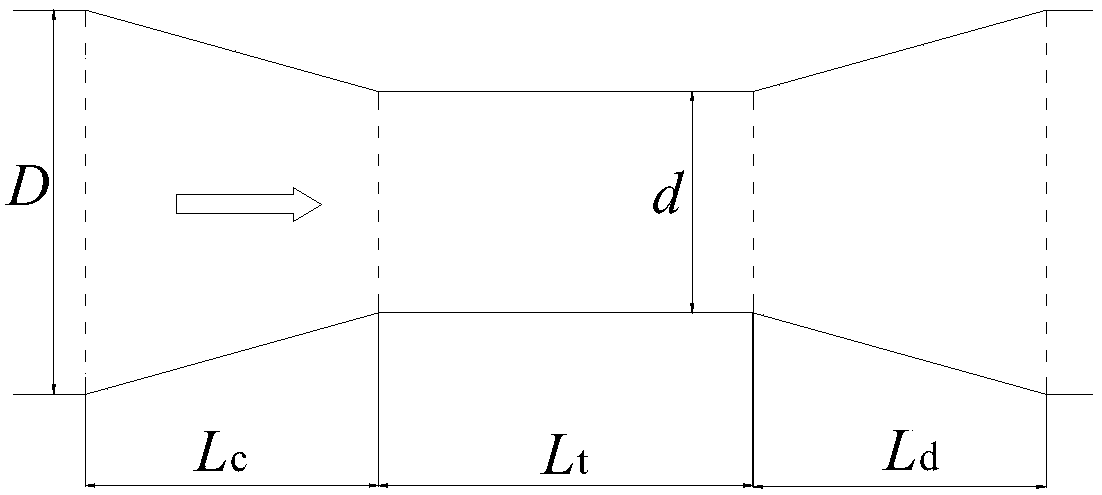

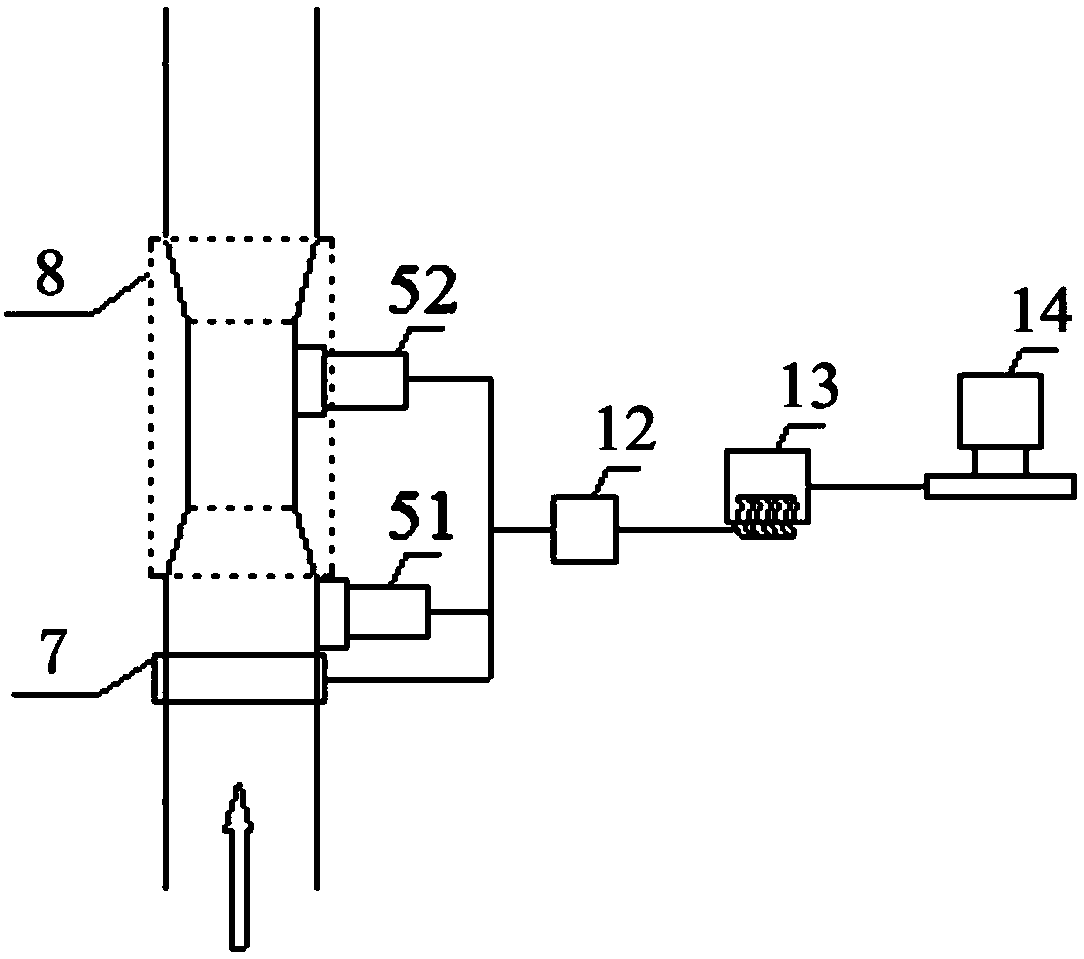

[0065] The pulverized coal dense phase pneumatic conveying system is mainly composed of gas source, material tank, conveying pipeline, valve, instrumentation, DCS monitoring control and data acquisition system and other units. For details, see figure 1 In the figure, 1 is a gas cylinder, 2 is a gas buffer tank, 31, 32, 33 are gas flowmeters, 4 is a delivery tank, 51, 52, 53, 54, 55 are pressure sensors, 6 is a solid mass flowmeter, 7 8 is a venturi tube, 9 is an electronic scale, 10 is a weighing tank, and 11 is a dust collector. The pulverized coal dense phase pneumatic conveying system provides gas into the conveying tank through the gas source, controls and adjusts the pressure of the conveying tank, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com