A concrete block pressure testing machine

A concrete block and pressure test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of real-time monitoring of block quality, large lifting stroke of oil cylinder, large volume of universal machine, etc. problems, to achieve the effect of lowering the center of gravity, facilitating adjustment, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

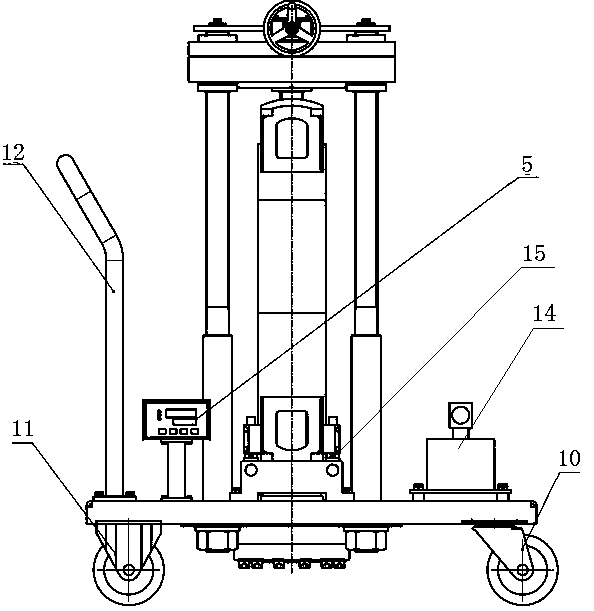

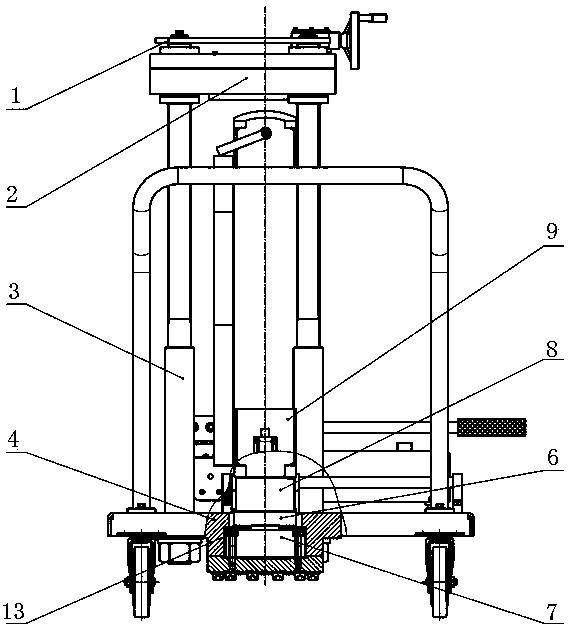

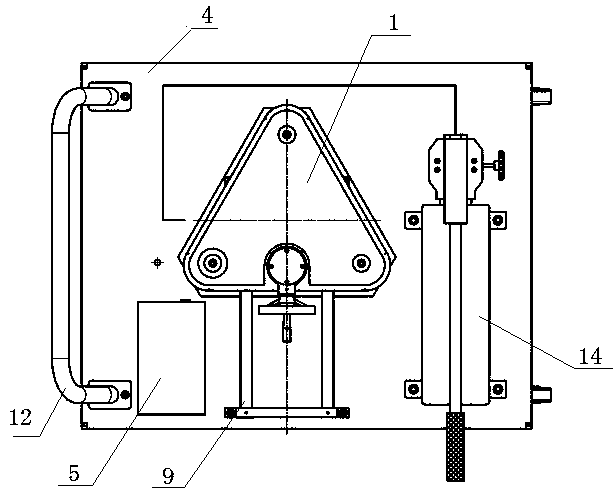

[0020] According to attached Figure 1-3 It can be seen that the present invention specifically relates to a concrete block pressure testing machine, comprising a movable pressure bearing platform 4, a pressure sensor 7 is arranged in the middle of the pressure bearing platform 4, a hydraulic jack 8 is fixed above the pressure sensor 7, and the hydraulic jack Above 8 is the sample moving platform 9, and three screw assemblies 3 are evenly distributed around the pressure sensor 7. A mobile carrying plate 2 that can move with the screw assembly 3 is provided, and a hand wheel for adjusting the lifting of the screw assembly 3 is provided above the mobile carrying plate 2. The pressure sensor 7 is connected to the digital display instrument box 5 on one side, and the hydraulic jack 8 is connected to the The hydraulic pumps 14 on the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com