Hydraulic lock loading test device

A testing device and hydraulic loading technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, fluid pressure actuation system components, etc., can solve the problem of inability to effectively detect the actual performance and comprehensive characteristics of hydraulic locks, and mutual influence , Affect the safety of the hydraulic lock control system and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

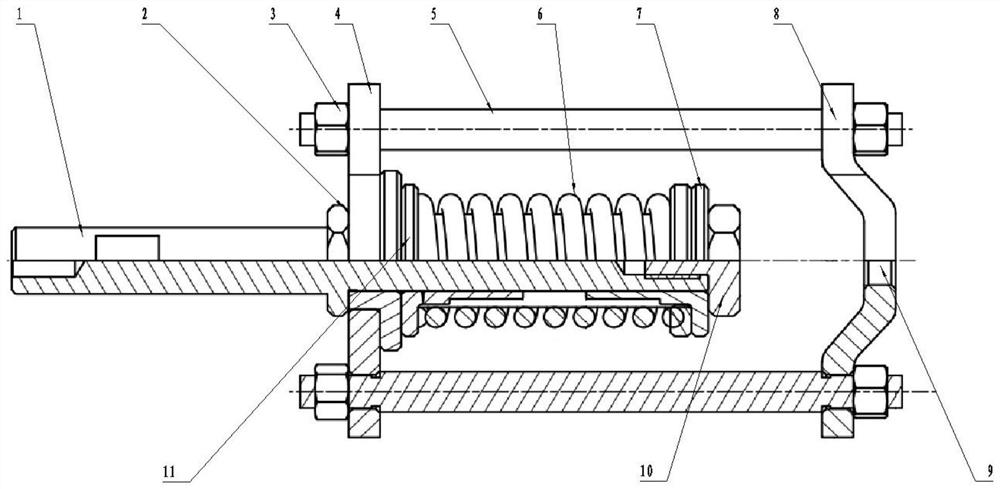

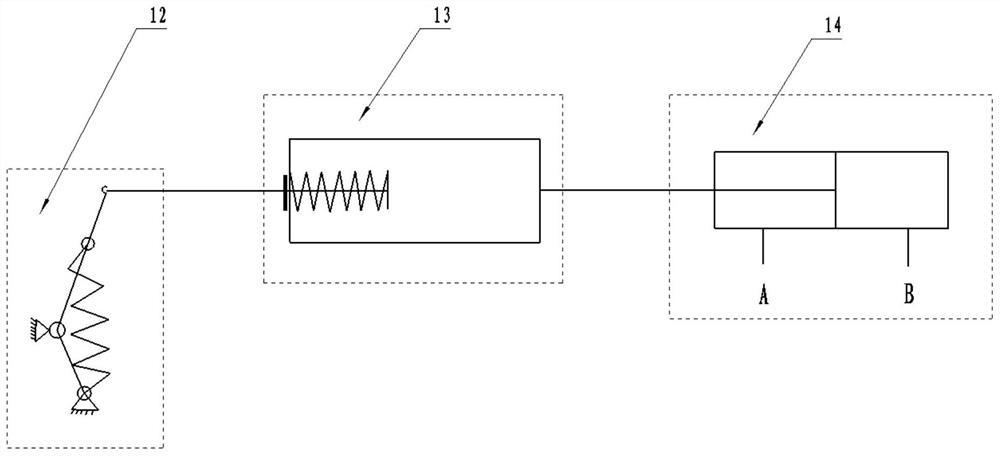

[0013] refer to figure 1 , figure 2 . In the preferred example described below, a hydraulic lock loading test device includes: a transmission link 1 that is coupled and connected to the hydraulic lock 12 at one end, and a loading cylinder connecting plate 8 that is connected to a hydraulic loading cylinder, wherein: the loading cylinder is connected The plate 8 adopts a bow-shaped connecting plate, and connects with the hydraulic loading cylinder through the loading cylinder connecting hole on the bow-shaped connecting plate. The loading cylinder connecting plate 8 connects the spring seat plate 4 through the circumferential loading connecting rod 5, and the loading connecting rod 5 passes through the back tightening nut 3 Carry out solid connection assembly, pre-installed with the spring guide sleeve 11, the opposite end spring guide sleeve 7 and the transmission link 1 of the loading spring 6 through the center hole of the spring seat plate 4, the spring guide sleeve 11 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com