Multi-drop-hammer millisecond delay loading experiment system

A loading experiment, millisecond-level technology, applied in measurement devices, impact testing, testing of machine/structural components, etc., can solve problems that do not conform to the nature of mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

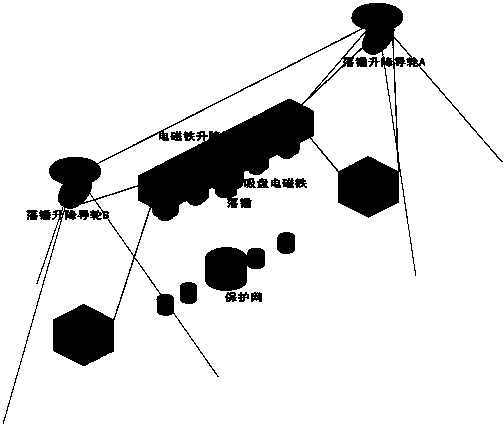

[0019] Such as figure 1 The multi-drop hammer millisecond-level delayed loading experiment system shown includes an electromagnet lifting guide wheel box, a single-chip microcomputer, a hoist, 5 drop hammer devices, and drop hammer lifting guide wheel A and drop weight lifting guide wheel B arranged at the same height. The drop weight lifting guide wheel A and the dropping weight lifting guide wheel B are fixedly connected with the tripod through the connecting shaft at the center thereof. The two ends of the rope pass through the guide rails of the drop weight lifting guide wheel A and the drop weight lifting guide wheel B and are fixedly connected with the left and right side walls of the electromagnet lifting guide wheel box respectively. Drop hammer lifting guide wheel A is a double guide wheel.

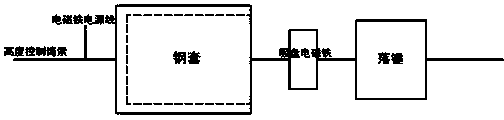

[0020] Such as figure 2 The drop hammer device shown: the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com