Electronic product significant defect rapid excitation method

An electronic product, fast technology, applied in the direction of measuring electricity, measuring electrical variables, thermal analysis of materials, etc., can solve problems such as difficult product testing, and achieve the effect of robust design and wide range of environmental condition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

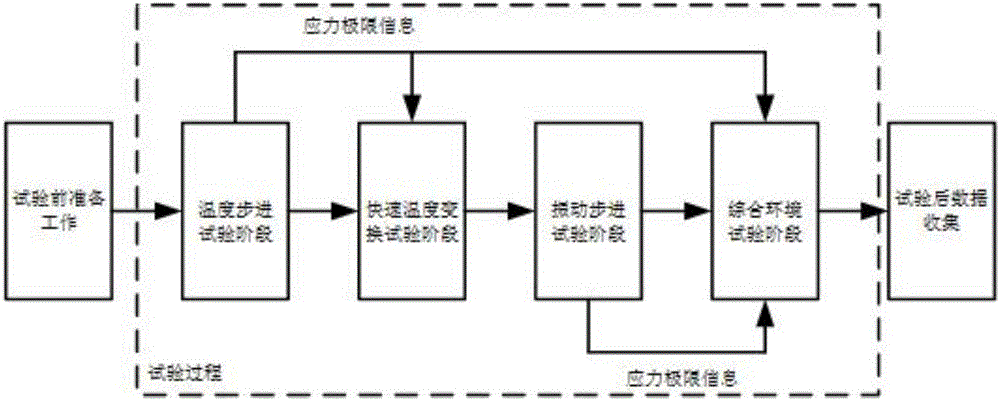

[0022] refer to figure 1 , The rapid excitation method for major defects in electronic products of the present invention is mainly composed of temperature step test steps, rapid temperature change test steps, vibration step test steps and comprehensive environmental test steps.

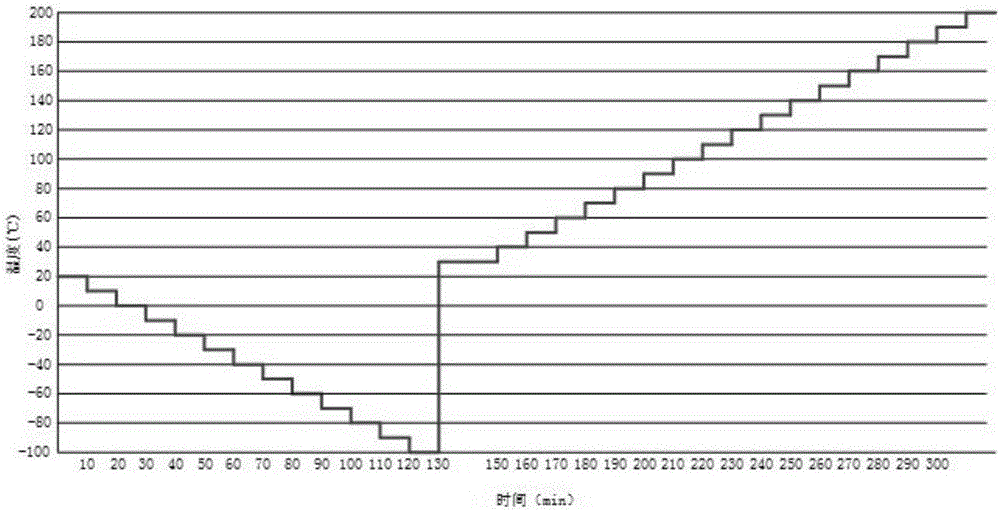

[0023] Step 1 is a temperature step test, which is used to obtain the low temperature working limit, low temperature damage limit, high temperature working limit and high temperature damage limit. Generally, the starting temperature of the test is the ambient temperature +20°C ~ +30°C, and at least one power-on and power-off start-up and load test are performed at each step when the temperature is stable. If the product test is normal, the temperature change is performed in the range of 10°C , and so on until a functional failure occurs. After returning the temperature to normal temperature and stabilizing, perform a power-on start-up and a load test to observe whether its function is restored to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com