Wireless charging receiving coil and fabrication method thereof

A wireless charging and receiving coil technology, applied in the direction of transformer/inductor coil/winding/connection, circuit, inductor, etc., can solve the problems of large area and difficult integration, and achieve high quality factor and strong power receiving ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

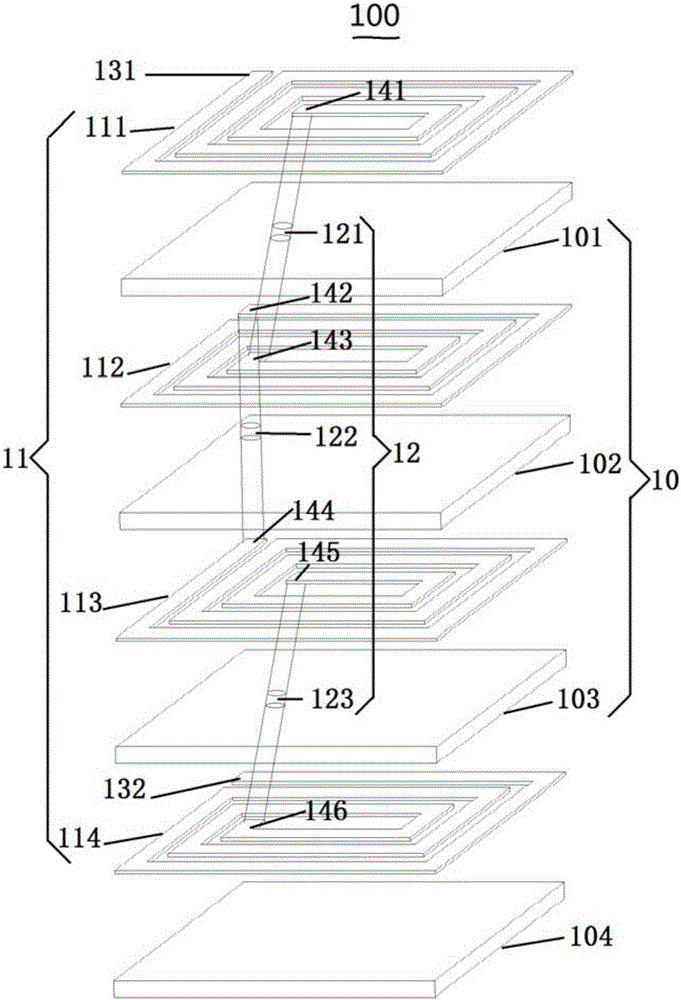

[0086] see figure 1 Shown is the structure of a wireless charging receiving coil provided in Embodiment 1 of the present application. The wireless charging receiving coil is a 4-layer series structure, including 1 layer of flexible substrate 104, 3 flexible insulating layers 10, and 4 conductive coil layers. 11, 3 vias 12, 2 terminals 131, 132. The bottom layer is the flexible substrate 104 as the base layer, the first conductive coil layer 114 , the first insulating layer 103 , the second conductive coil layer 113 , the second insulating layer 102 . . . up to the fourth conductive layer. The coil layers 111 are separated by an insulating layer 10 between adjacent conductive coil layers, forming a multi-layer structure in which the conductive coil layers and the insulating layers are alternately stacked.

[0087] The conductive coil layers of different layers have the same direction after being connected in series, and the inner end 146 of the first conductive coil layer 114 ...

Embodiment 2

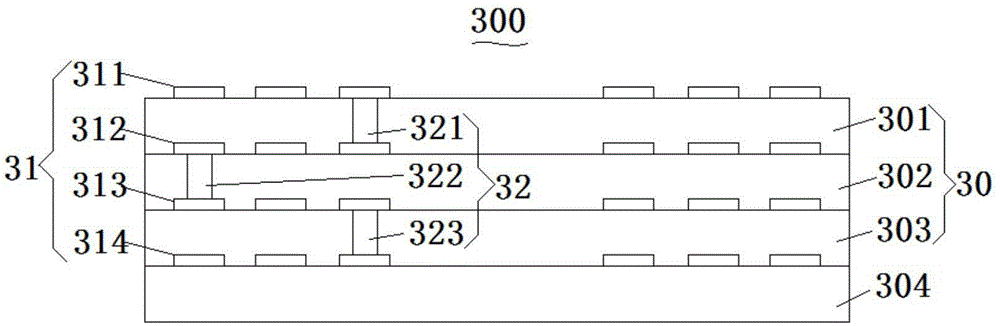

[0095] see Figure 4 Shown is the structure of a wireless charging receiving coil provided by Embodiment 2 of the present application. The wireless charging receiving coil is a 4-layer series-parallel structure, in which the upper two layers 211, 212 are connected in parallel, and the lower two layers 213, 214 are connected in parallel. , and then the upper two layers are connected in series with the lower two layers, which also includes 1 layer of flexible substrate 204 , 3 flexible insulating layers 20 , 4 conductive coil layers 21 , 5 via holes 22 , and 2 terminals 231 , 232 . The bottom layer is the base layer 204, and upwards are the first conductive coil layer 214, the first insulating layer 203, the second conductive coil layer 213, the second insulating layer 202... until the fourth conductive coil layer 211, Adjacent conductive coil layers are separated by insulating layers 20 to form a multi-layer structure in which conductive coils and insulating layers are stacked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com