Screw host loading and unloading special press

A main engine and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of strong applicability and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

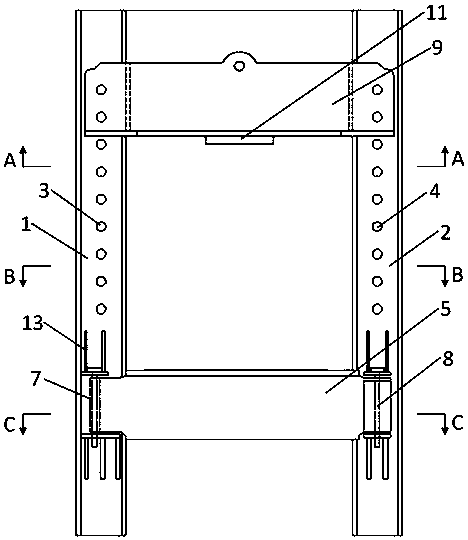

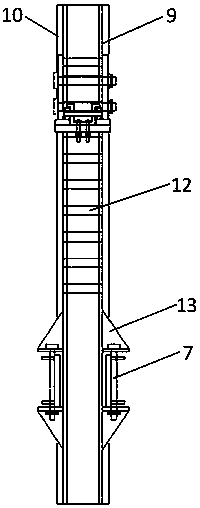

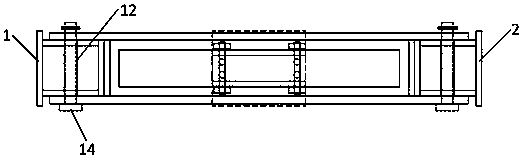

[0037] Such as Figure 1~6 As shown in the figure, a special press machine for loading and unloading the screw main frame includes a left vertical frame 1 and a right vertical frame 2 parallel to each other, and the lower side of the left vertical frame 1 and the right vertical frame 2 is provided with an I that can open and close the screw main frame. No. support plate 5, the upper part of the left vertical frame 1 and the right vertical frame 2 is provided with the No. I adjusting plate 9 and the No. II adjusting plate 10 that can be adjusted vertically, and the No. I adjusting plate 9 and the No. II adjusting plate 10 below A fixed plate 11 that moves horizontally is provided, and a hydraulic cylinder for decompressing the rotor is fixed at the lower end of the fixed plate 11 .

[0038] In the present invention, the No. 1 support plate 5 can be opened, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com