Full-automatic multifunction EVA baking equipment

A baking equipment and multi-functional technology, applied in the field of automatic multi-functional EVA baking equipment, can solve the problems of reducing the production capacity ratio, long heating time, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

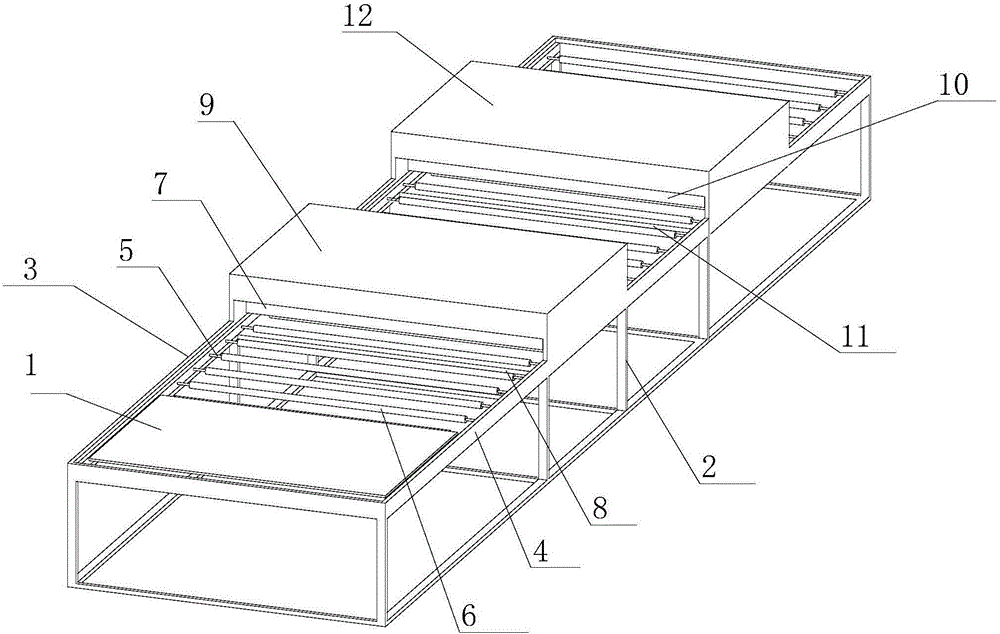

[0016] refer to figure 1 , the present invention proposes a fully automatic multi-functional EVA baking equipment, comprising a carrier plate 1, a baking device, a first detection device, a second detection device, a timing device, and a control device, wherein:

[0017] The baking device includes a support 2 , a first heating assembly, a second heating assembly and a transport mechanism installed on the support 2 for transporting the carrier plate 1 . The transmission mechanism includes a first support plate 3, a second support plate 4, a set of transmission rollers, and a driving mechanism. The first support plate 3 and the second support plate 4 are arranged horizontally and parallel to each other. The first support plate 3 and the second support plate 4 They are all installed on the bracket 2 and there is a gap reserved between the first support plate 3 and the second support plate 4 to form a transmission channel. The transmission roller group is arranged in the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com