Pneumatic clamping device for workpieces

A pneumatic clamping and workpiece technology, applied in the direction of manufacturing tools, stamping machines, presses, etc., can solve the problems of structural and functional limitations, equipment can not be completed, complex operation of equipment, etc., to achieve high production efficiency, fast action, simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

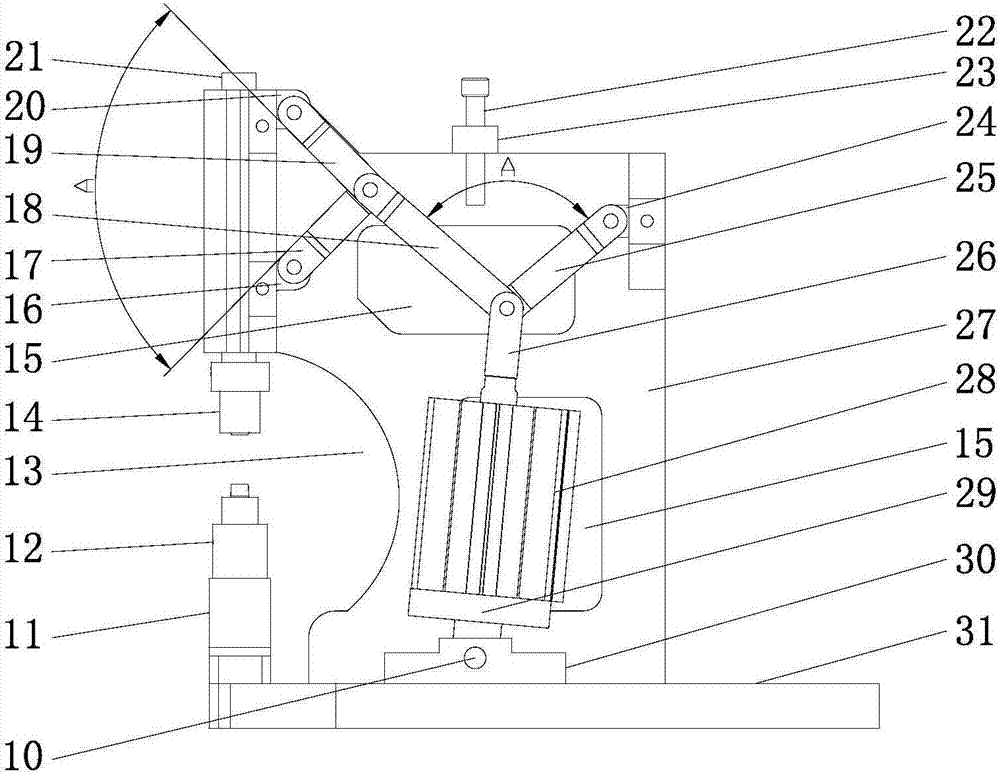

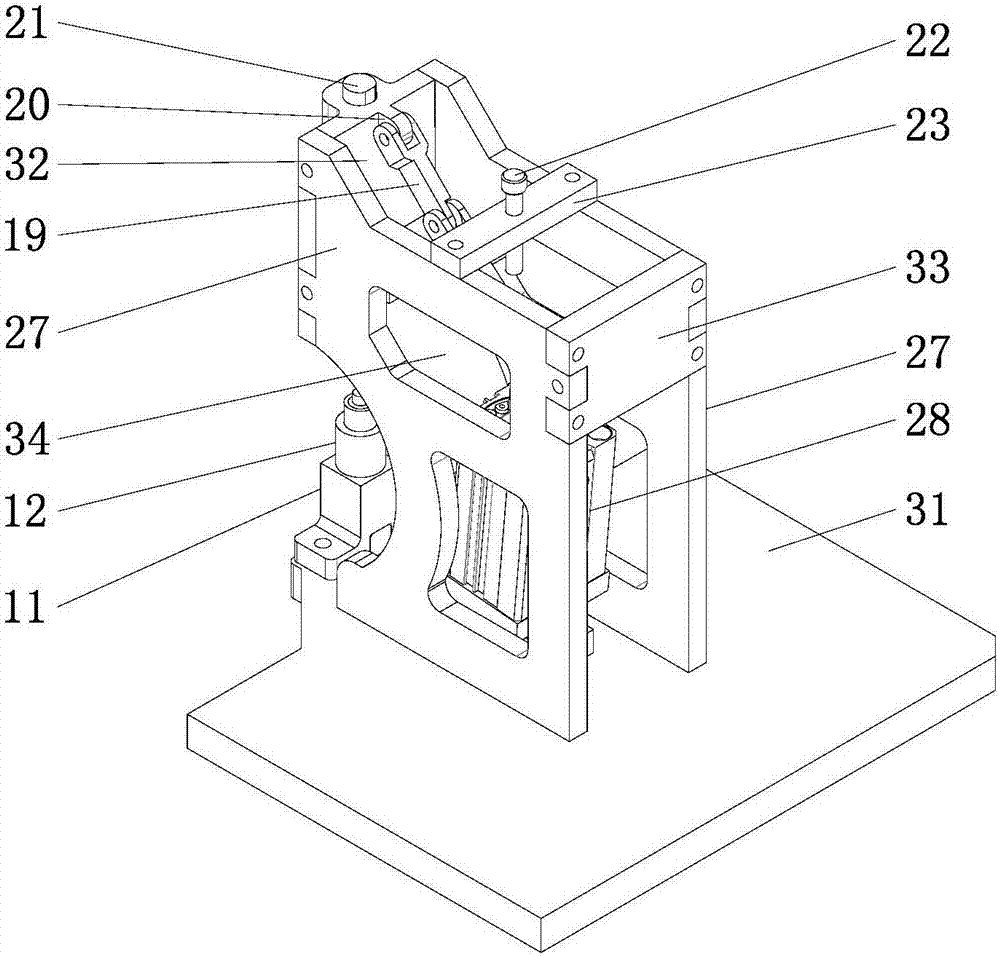

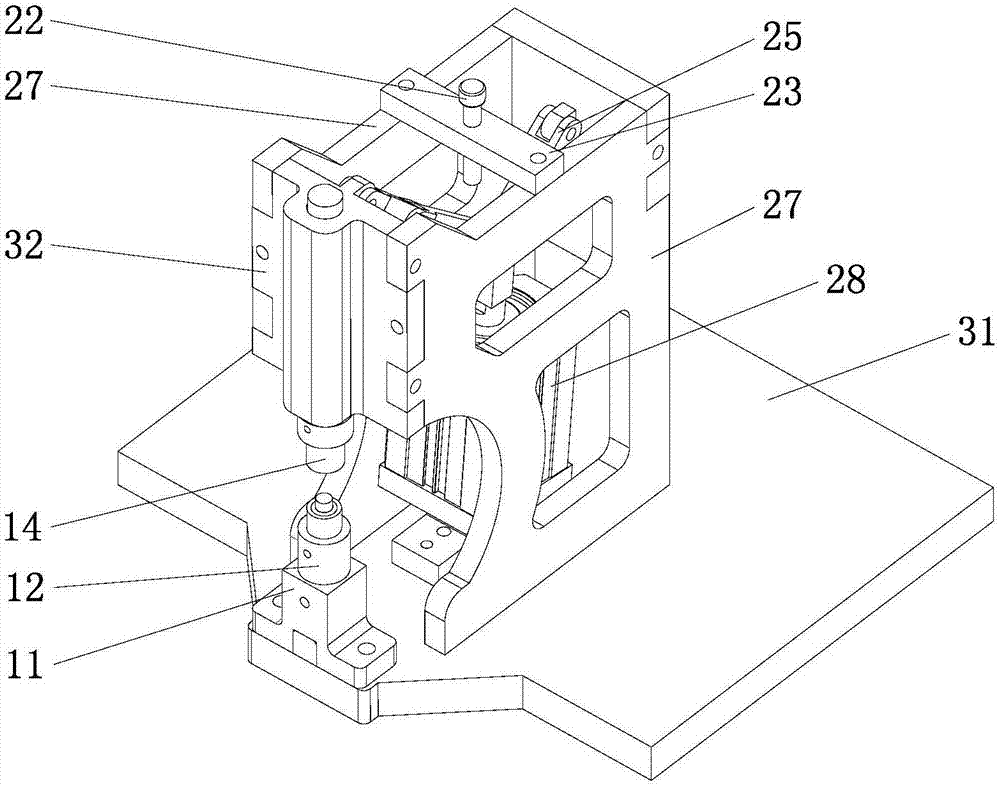

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 6 :

[0024] The pneumatic clamping device of the workpiece includes a frame with a base 31, one end of the cylinder 28 is hinged on the base 31, and the other end is hinged with one end of the first connecting rod 25 and the second connecting rod 18 at the same time, and the first connecting rod 25 The other end of the second link 18 is hinged on the rear wall 33 of the frame, and the other end of the second link 18 is hinged with one end of the third link 19 and the fourth link 17 at the same time, and the other end of the third link 19 is hinged on the frame. On the front wall 32 of the front wall 32 of the rack, the vertical slideway 41 of the front wall 32 of the frame slides to be provided with a slide bar 21, and the lower end of the slide bar 21 is fixed with an upper module 14, and on the base 31 directly below the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com