Toothpaste tube with two detachable ends

The technology of toothpaste and front canister is applied in the field of double-head detachable toothpaste canisters, which can solve the problems of increasing garbage discharge, large usage amount, and increasing use cost, and achieve the effects of reducing garbage discharge, saving use cost, and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

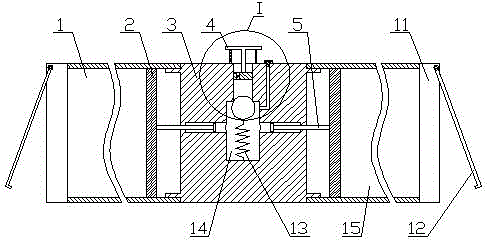

[0024] Such as figure 1 A double-ended detachable toothpaste cartridge is shown, including a front cylinder body 1 and a rear cylinder body 15 with a piston 2 slidably connected inside, and a piston 2 located between the front cylinder body 1 and the rear cylinder body 15 that can push the piston 2 along the front The cylinder 1 and the rear cylinder 15 are pushers that move axially. The ends of the front cylinder 1 and the rear cylinder 15 away from the pusher are provided with a flat paste outlet 11 and a sealing cover 12 that seals the paste outlet 11 .

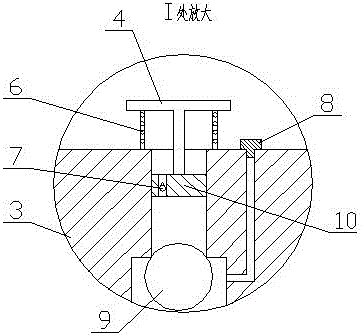

[0025] The pushing device in the present embodiment comprises two ends and the front cylindrical body 1, the rear cylindrical body 15 respectively by the mounting base 3 that is threadedly connected, the mounting base 3 is provided with the air chamber 14 and the section is smaller than the air chamber 14 and the air chamber 14 is connected with the air chamber 14. The compressed gas channel connected to the atmosphere, th...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the pushing device in this embodiment includes an installation box 16 fixedly connected to the front cylinder body 1 and the rear cylinder body 15 at both ends, and an electric motor 17 and an electric motor 17 are fixed in the installation box 16. The hollow shaft 22 rotated by the electric motor 17 is fixed with a driven gear 20 on the hollow shaft 22 , and the output shaft of the electric motor 17 is fixed with a driving gear 19 meshing with the driven gear 20 . The switch 18 of the electric motor 17 is arranged on the surface of the installation box. It can be three independent buttons, respectively controlling the forward rotation, reverse rotation and stop of the electric motor, or it can be a slider switch, which slides three different positions for forward rotation and reverse rotation. and stop control of the three states. The hollow shaft 22 is connected with the installation box 16 through the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com