Anti-shake can hanging plate structure and self-loading and unloading type garbage truck

A self-loading and plate-structure technology, which is applied in the direction of garbage receptacle, transportation and packaging, can solve the problems of limit bar fatigue, aggravated swing, scrapping of plastic trash cans, etc., and achieves increased service life, small jitter, and high efficiency. The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

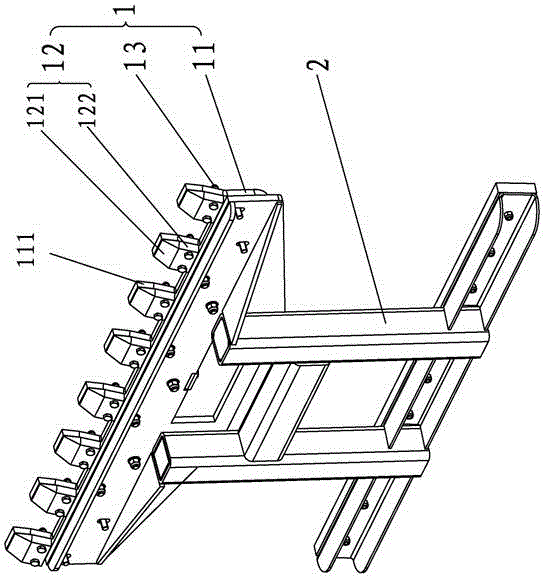

[0024] Such as figure 1 As shown, the anti-shake hanging bucket plate structure 1 of the present invention mainly includes a bucket hanging plate 11 and a hanging tooth gasket 12 .

[0025] The bucket hanging plate 11 can adopt the existing structure, and the hanging bucket plate 11 is integrally formed with hanging teeth 111.

[0026] The hanger gasket 12 matches the shape of the hanger 111, and the hanger gasket 12 is arranged on the hanger 111. Preferably, the hanger gasket 12 is attached to the hanger 111, and the end of the hanger gasket 12 is provided with chamfers. The hanger spacer 12 can be assembled on the hanger 111 by a fastener 13 . There are multiple fasteners 13, and the multiple fasteners 13 respectively include matching bolts and nuts.

[0027] Preferably, the hanger spacer 12 includes a tooth tip 121 and a tooth root 122 connected together, and the tooth tip 121 and the tooth root 122 can be integrally formed. The thickness from the tip 121 to the root 122...

Embodiment 2

[0029] In this embodiment, the self-loading and unloading garbage truck mainly includes a hanging plate frame 2 and an anti-shake type hanging bucket plate structure 1, and the anti-shake type hanging bucket plate structure 1 can adopt the above structure, which is the same structure as the first embodiment, and is not described here. Let me repeat.

[0030] Hanging barrel plate 11 is set on the hanging plate frame 2, and hanging barrel plate 11 is provided with hanging tooth 111, and hanging tooth gasket 12 is set on the hanging tooth 111, and the shape of hanging tooth gasket 12 matches with described hanging tooth 111. The hanging tooth gasket 12 and the hanging plate frame 2 are respectively located on the same side of the bucket hanging plate 11 , and the root of the tooth root 122 of the hanging tooth gasket 12 leans against the end surface of the hanging plate frame 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com