A sewage treatment method and system

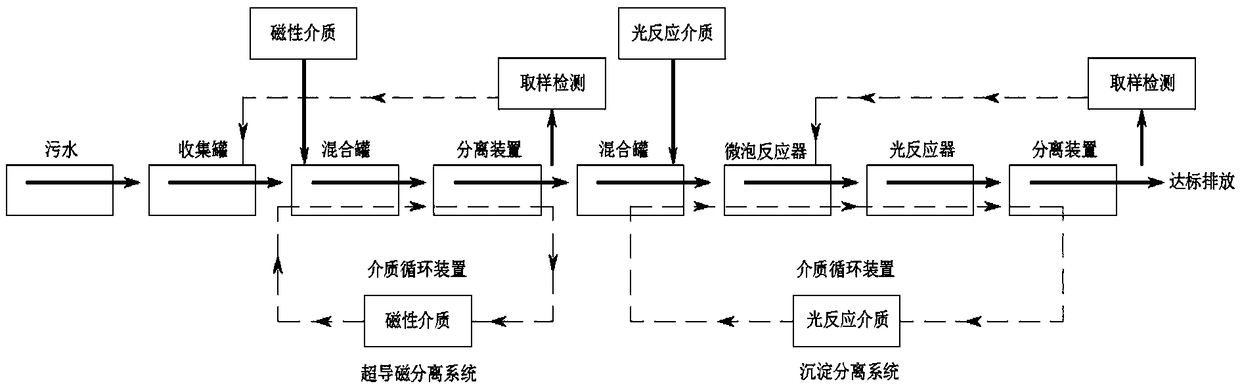

A sewage treatment method and a sewage treatment system technology, applied in the field of water treatment, can solve the problems of low efficiency of sewage metal pollution treatment, etc., and achieve the effect of improving the effect of light reaction, improving the effect and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

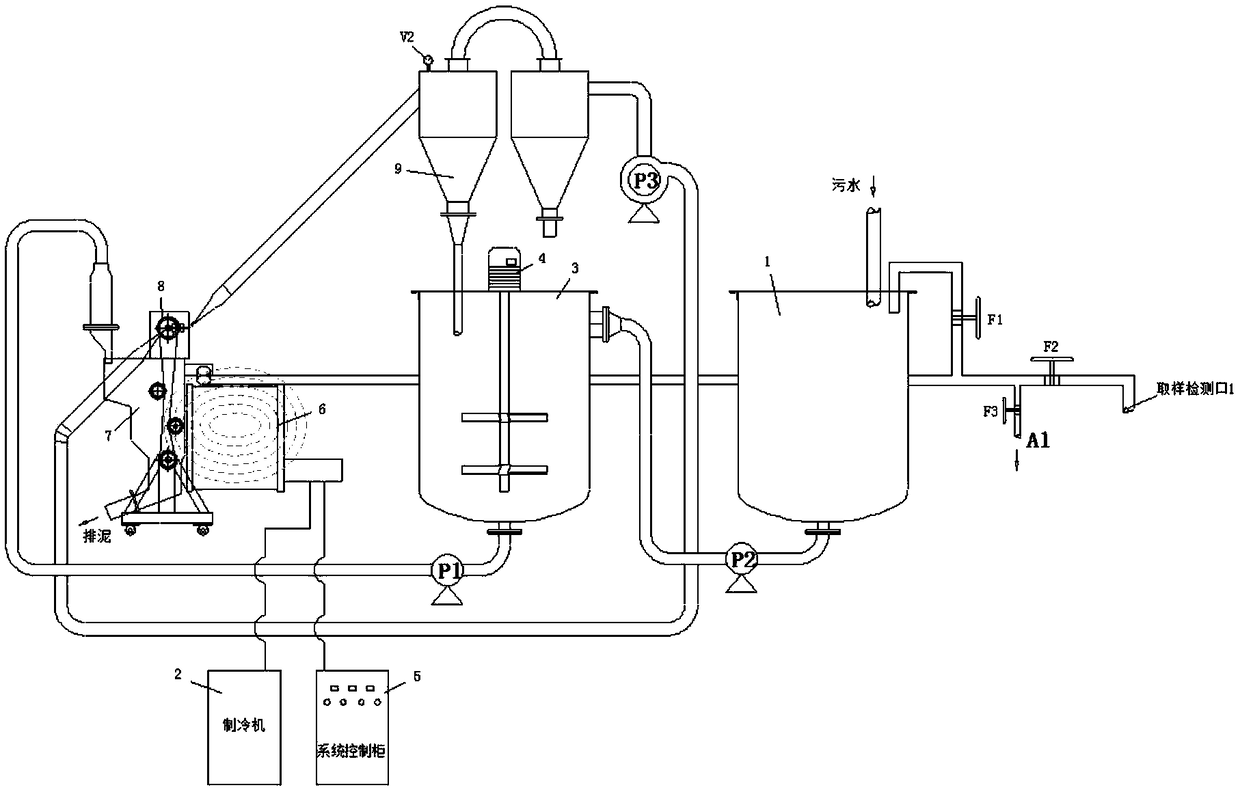

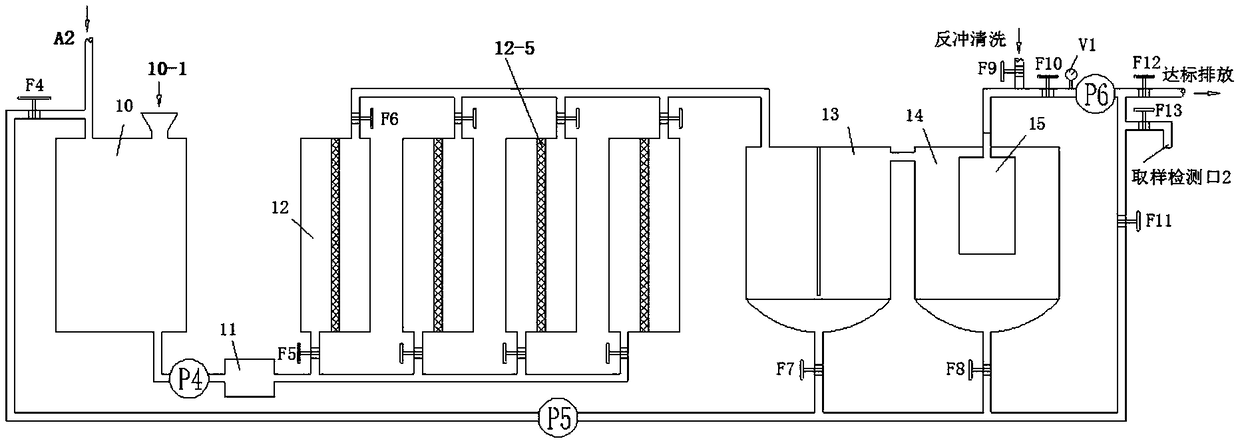

Examples

Embodiment 1

[0126] (1) H with a mass ratio of (2.8-3.2):1 12 Cl 3 FeO 6 and FeC 12 4H 2 O is dissolved in ionized water, wherein, the weight of solute added per 100ml of ionized water is: 6.5-7.5g;

[0127] (2) Then heat the solution in step (1) with a water bath, and keep stirring to raise the temperature. During the heating process, nitrogen protection is introduced. After the temperature is raised to 40-60°C, concentrated ammonia water is added dropwise until the pH of the solution is about 9, and the temperature is kept stable. , the reaction time is more than 1 hour;

[0128] (3) After the reaction, the liquid in the flask is transferred to the beaker, and left to settle;

[0129] (4) move out the supernatant of the mixture after the static precipitation, add deionized water to wash three times until the pH of the washing solution is about 7, and obtain nanometer ferric oxide;

[0130] (5) Use a magnet to absorb at the bottom of the beaker, drain the water and then add deionize...

Embodiment 2

[0137] (1) 25.3g of H 12 Cl 3 FeO 6 and 8.6g of FeC 12 4H 2 O, dissolved in a 500ml deionized water beaker, transferred to a three-necked flask after completely dissolving;

[0138] (2) heating the three-necked flask in a water bath, stirring constantly, feeding nitrogen protection during the heating process;

[0139] (3) Warm up to 60°C and add concentrated ammonia water dropwise to control the pH to about 9;

[0140] (4) Keep the temperature stable, and the reaction time is 1 hour;

[0141] (5) Transfer the liquid in the bottle to a beaker, and let it settle;

[0142] (6) remove supernatant water, add deionized water to wash three times, control about PH7, obtain 9.8 grams of nanometer ferric oxide;

[0143] (7) Use a 3000Gs permanent magnet to absorb at the bottom of the beaker, drain the water and then add 300ml of deionized water;

[0144] (8) Add 200ml quantum carbon liquid to the reaction, and stir at the same time, the rotation speed is 500r / min, and the stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com