Printed fabric for indicating different humidity, preparation method of printed fabric, exercise intensity indicator and application of printed fabric

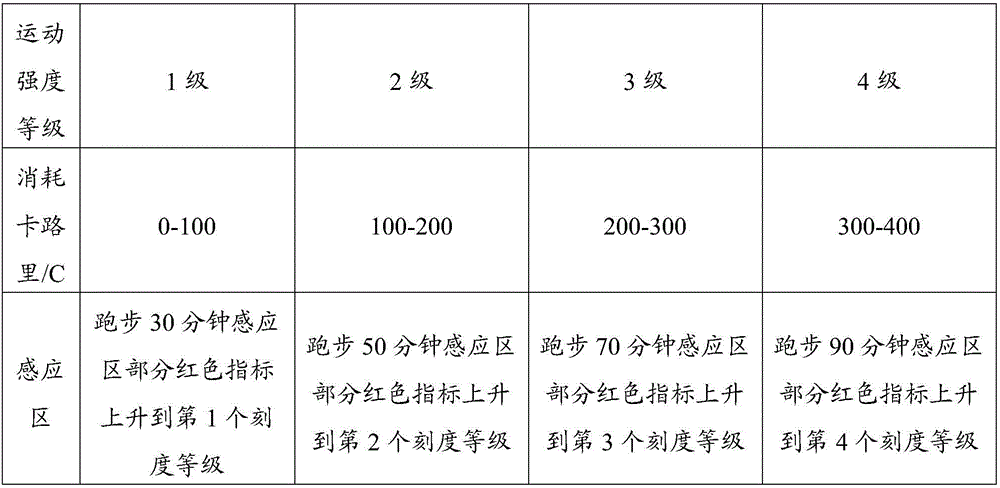

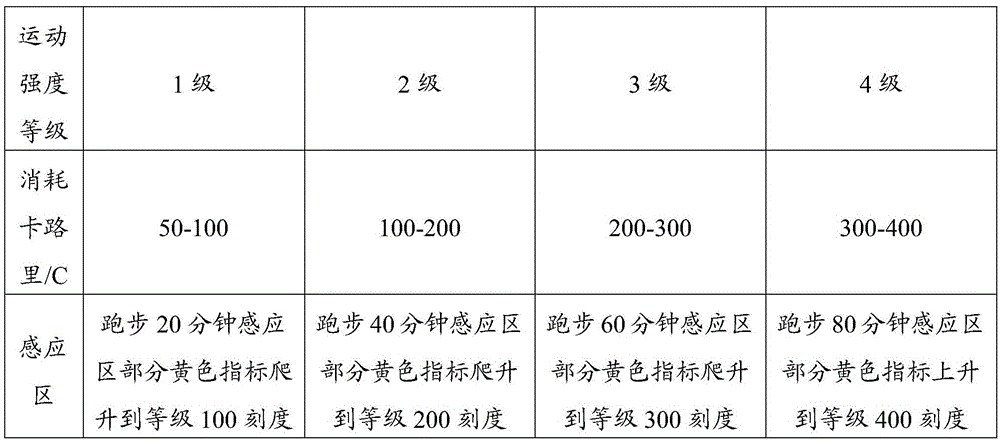

A technology of exercise intensity and indicators, applied in the field of exercise intensity indicators and printed fabrics, which can solve the problems of increased exercise load, inconvenient use, and inability to realize positioning and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Correspondingly, the present invention provides a kind of preparation method that is used to indicate the printed fabric of different humidity, comprises the following steps:

[0062] Provide printed fabrics to be finished;

[0063] The printed fabric to be finished is subjected to hydrophilic finishing, water-repellent finishing and water-changing printing respectively to obtain printed fabrics for indicating different humidity;

[0064] The printed fabric for indicating different humidity includes: a sensing area and a display area surrounding the sensing area; the sensing area sequentially includes a weakly hydrophilic fabric part, a moderately hydrophilic fabric part and a strongly hydrophilic fabric part; the The surface of the sensing area is compounded with a water-changing printing layer;

[0065] The display area is a part of the printed fabric that has undergone water-repellent finishing;

[0066] The weakly hydrophilic fabric part is formed through water-re...

Embodiment 1

[0093] (1): Use piqué fabric (32S pure cotton twill piqué dyed fabric, provided by Guangdong Esquel Textile Co., Ltd.) as the base fabric, first use color paste (the yellow color of Changzhou Caiyi Chemical Co., Ltd.) on the fabric base fabric Color paste SP058, solid content is 70wt%), printed by flat screen printing (200 mesh) figure 1 The pattern shown in the display area is dried until the pattern ink is completely dry, and the printed fabric to be finished is obtained; wherein, the printing speed is 35 m / min, the printing paste is applied, and the pressure is adjusted so that the amount of glue is controlled at 10%; at 160 ° C Bake for 2 minutes to make it fully fixed; the length of the sensing area is 15CM, and the width is 0.5CM.

[0094] (2): In the bottom area of the induction area (length 5cm), use a screen with an opening rate of 30% for water-repellent finishing printing, the middle area (length 7cm) does not do finishing, and the top area (length 3cm) does openi...

Embodiment 2

[0106] (1): Use piqué fabric (20S pure cotton piqué fabric, provided by Guangdong Deyongjia Company) as the base fabric, first use color paste (orange color paste SP268 from Changzhou Caiyi Chemical Co., Ltd.) on the fabric base fabric ), printed by flat screen printing (200 mesh) figure 1 The display area pattern shown is dried until the pattern ink is completely dry, and the printed fabric to be finished is obtained; wherein, the flat screen printing process is the same as that in Example 1; the length of the sensing area is 15 cm, and the width is 0.5 cm.

[0107] (2): In the bottom area (length 5cm) of the induction area, a screen with an opening rate of 40% is used for water-repellent finishing printing, the middle area (length 10cm) is not finished, and the top area (length 5cm) is opened Hydrophilic finish printing with a porosity of 40% yields a second intermediate fabric.

[0108] Among them, the slurry for water-repellent finishing printing includes the following co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com