Vehicle-mounted dust collection and air inflation integrated air pump

An integrated, air pump technology, used in vacuum cleaners, pumps, piston pumps, etc., can solve problems such as damage to the car environment, air leakage, inability to drive, tire puncture, etc., to achieve obvious cleaning effect, convenient access to electricity, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

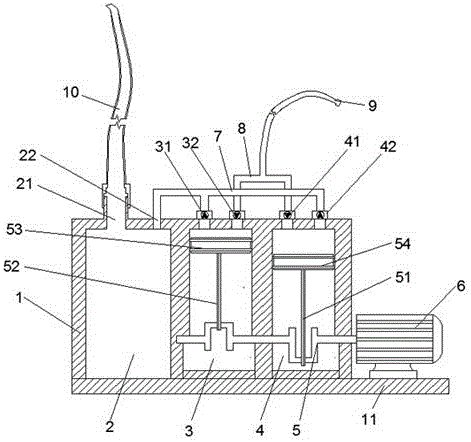

[0017] combined with figure 1 As shown, a vehicle-mounted vacuum and inflatable integrated air pump includes a pump body 1 and a base 11 integrally connected with the pump body 1. The pump body 1 is respectively provided with a foreign matter chamber 2, a first piston chamber 3 and a second piston chamber. 4. A motor 6 is installed on the base 11, and the drive shaft of the motor 6 is connected to a crankshaft 5, and the crankshaft 5 runs through the pump body 1 and is respectively hinged and arranged on the first piston assembly arranged in the first piston chamber 3. The second piston assembly in the second piston chamber 4 is hinged; the upper end of the first piston chamber 3 is provided with a first exhaust check valve 32 and a first intake check valve 31, and the upper end of the second piston chamber 4 is provided with There is a second exhaust one-way valve 41 and a second intake one-way valve 42. The foreign body chamber 2 is provided with an exhaust port 22, and the ...

Embodiment 2

[0023] In order to further realize the present invention, on the basis of embodiment 1, in conjunction with figure 1 As shown, the first piston assembly is composed of the first connecting rod 52 and the first piston 53 hinged with the other end of the first connecting rod 52, and the second piston assembly is composed of the second connecting rod 51 and the second connecting rod. 51 the second piston 54 that the other end is hinged forms.

[0024] Further, the dust suction pipe 10 is connected to the air inlet 21 through threads, and the other end of the dust suction pipe 10 is designed as a flat mouth, with a section length of 2 cm and a width of 4 mm. The smaller the cross-sectional area, the greater the suction force obtained, and the better the dust collection effect.

[0025] Preferably, the material of the suction pipe 10 is a spiral plastic hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com