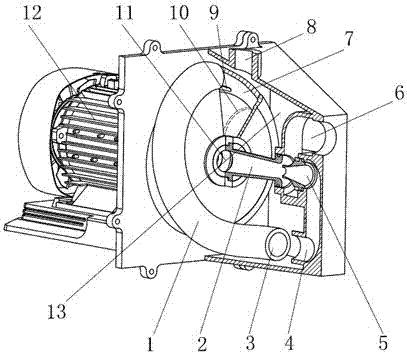

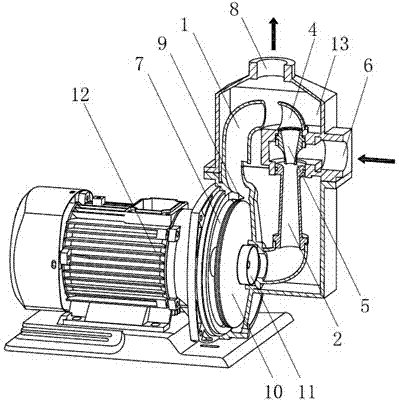

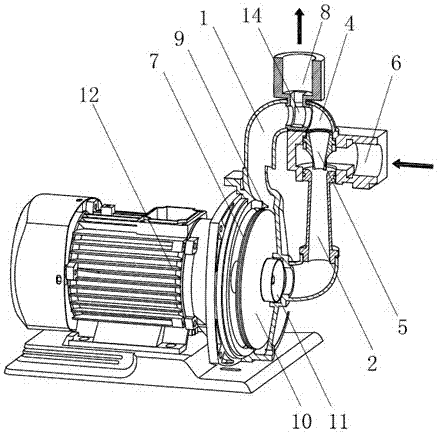

Low noise self-priming compound pump

A compound pump, low-noise technology, applied in the direction of pump, drive pump, pump components, etc., can solve the problem of fluid flow into the split pressure water chamber is not smooth, high operating noise, etc., to solve the problem of flow noise and flow loss, pump body Weight reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: When the low-noise self-priming compound pump of this embodiment is working, a part of the fluid in the centrifugal volute chamber 7 of the compound pump is driven by the high-speed rotation of the centrifugal impeller 10, and after obtaining kinetic energy, it passes through the centrifugal volute chamber tongue 9 under the action of centrifugal force. After passing through the single-entry flow channel 1, the diversion flows smoothly and smoothly into the diversion pressure water chamber 13 or the diversion tee 14, and quickly converts kinetic energy into pressure potential energy. Therefore avoid the collision of guide vane on the guide vane plate 15 of the traditional jet pump and centrifugal impeller 10, scrape and flow noise and the flow loss of high-speed fluid impact jet pump guide vane 16, jet pump guide disc 17, see Figure 4 . Part of the fluid (high speed or high pressure) entering the diversion pressurized water chamber 13 or the diversion tee 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com