Cylindrical shell section regenerative electric heat storage device and heating method

A regenerative, electric thermal storage technology, applied in thermal storage heaters, thermal storage equipment, fluid heaters, etc., can solve problems such as electric energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

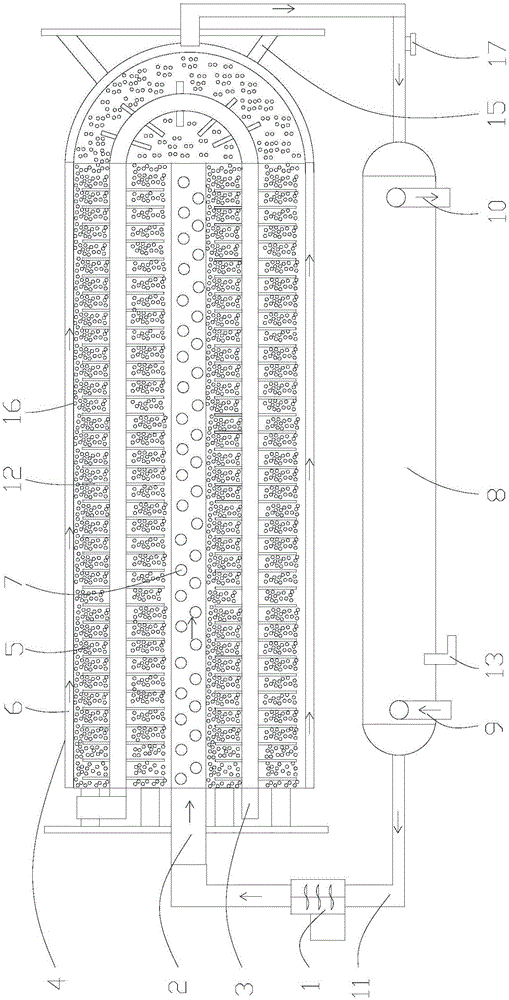

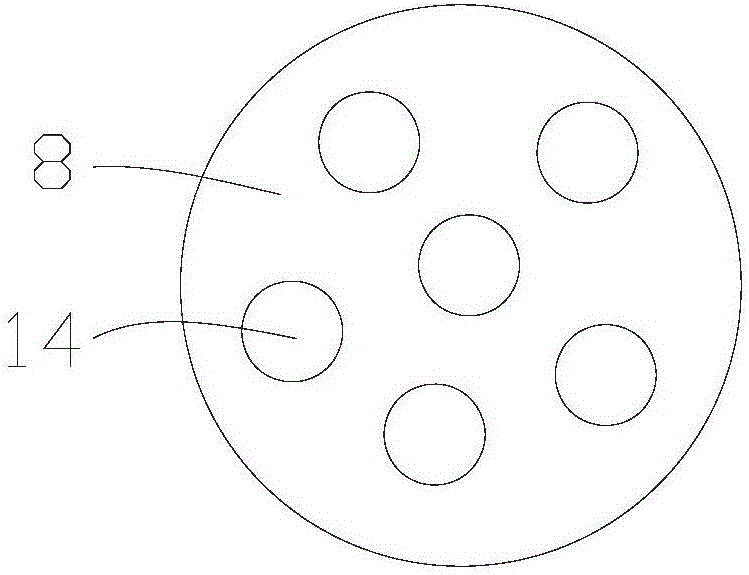

[0031] Example 1, such as figure 1 and figure 2 As shown in the figure, a tube-section heat storage electric heat storage device includes a hot air pipe I11 and a hot air blower I1 arranged on the hot air pipe I11, and the output end of the hot air pipe I11 is connected to the input end of the air pipe I2 , blow the air in the hot air pipe I11 into the air pipe I2.

[0032] The air duct I2 is arranged at the center of the heat storage cylinder 4, and the outer wall of the air duct I2 inside the heat storage cylinder 4 has an air duct hole I7, so that air can enter other spaces of the heat storage cylinder 4 through the air duct hole I7.

[0033] The hot air pipe I11 communicates with the air pipe I2 and the heat storage cylinder 4 provided with one. The heat storage cylinder 4 is carried on the bracket I15.

[0034] The inside of the heat storage cylinder 4 is provided with a heating pipe I3, and the heating pipe I3 is arranged in a circumferential direction on the outer...

Embodiment 2

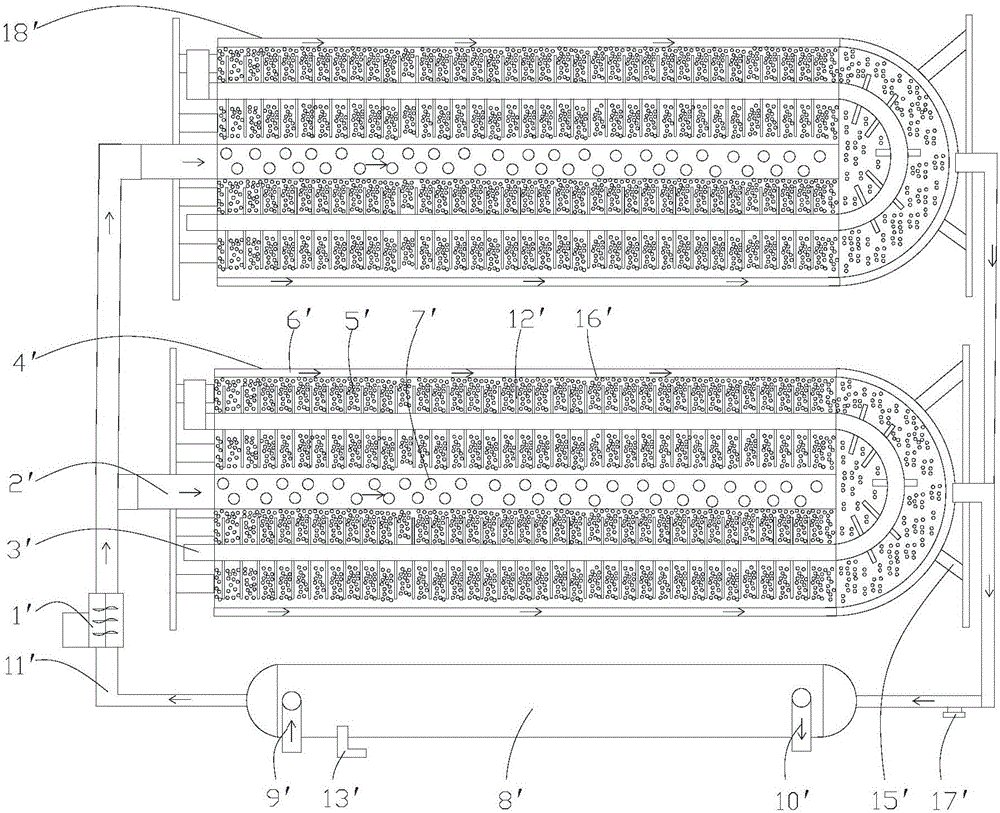

[0048] Example 2, such as image 3 and Figure 4 As shown, a tube-section heat storage electric heat storage device includes a heat storage cylinder, a hot air pipe II11' and a hot air blower II1' arranged on the hot air pipe II11', and the heat storage cylinder is provided with two , are respectively the first heat storage cylinder 4' and the second heat storage cylinder 18'. The first heat storage cylinder 4' and the second heat storage cylinder 18' are carried on the support II 15'.

[0049] The first heat storage cylinder 4' and the second heat storage cylinder 18' are the same heat storage mechanism, and the hot air pipe II11' is the same as the first heat storage cylinder 4' and the second heat storage cylinder 18' respectively. connected.

[0050] In the first heat storage cylinder 4', the output end of the hot air pipe II11' is connected with the input end of the air pipe II2', and the air in the hot air pipe II11' is blown into the air pipe II2'.

[0051] The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com